4.2 Capitalism – naturally

Business can learn to integrate ecological thinking into the core of its thinking and become the hub of a sustainable society. This is the claim of the business learns position. As environmentalists have spent over 30 years portraying business as the arch-villain of the piece, this is a grand claim. One of the people who have stated it most clearly is Ray Anderson, head of the US carpet giant Interface (Figure 3a). Here is the story of his dramatic conversion to a different way of thinking about business and the natural world.

Ray's story: ‘doing well by doing good’

Ray Anderson was in the business of selling vast amounts of carpet around the world. He had no regard for the environment, beyond recognising the obligation to ‘comply, comply, comply’ with regulations. The company was a heavy user of petrochemicals and, once the products left the factory gate, the company would not see them again; their last home would be landfill. One day in 1994 Anderson was asked to talk to a group of his executives about the company's environmental vision. He realised they didn't have one, and he chanced on a book called The Ecology of Commerce by Paul Hawken (1995). The book transformed the way he thought about the whole business world:

While business is part of the problem; it can also be a part of the solution. Business is the largest, wealthiest, most pervasive institution on Earth, and responsible for most of the damage. It must take the lead in directing the Earth away from collapse, and toward sustainability and restoration…

I believe we have come to the threshold of the next industrial revolution. At Interface, we seek to become the first sustainable corporation in the world, and, following that, the first restorative company. It means creating the technologies of the future – kinder, gentler technologies that emulate nature's systems. I believe that's where we will find the right model. Ultimately, I believe we must learn to depend solely on available income the way a forest does, not on our precious stores of natural capital. Linear practices must be replaced by cyclical ones. That's nature's way… We look forward to the day when our factories have no smokestacks and no effluents. If successful, we'll spend the rest of our days harvesting yesteryear's carpets, recycling old petrochemicals into new materials, and converting sunlight into energy. There will be zero scrap going into landfills and zero emissions into the biosphere. Literally, our company will grow by cleaning up the world, not by polluting or degrading it. We'll be doing well by doing good. That's the vision. Is it a dream? Certainly, but it is a dream we share with our 7,500 associates, our vendors, and our customers. Everyone will have to dream this dream to make it a reality, but until then, we are committed to leading the way.

(Anderson, 2002)

The company has been applying life cycle analysis (LCA) to ‘close the loop’ of its resource impacts through efficiencies and cutting pollution (Figure 10). Perhaps most interesting is the new way it started to think about the business's relationship with customers. It seeks to supply service and value rather than material goods. For example, the company leases floor coverings, replacing only those carpet tiles that wear (and recycling them). The result can be reduced environmental impact, satisfied customers and competitive advantage. But it is still a carpet company, turning a profit, with 7500 employees working in 34 countries.

The company makes some grand claims, but its corporate reporting addresses sustainability. Indeed, it claims to have produced the first corporate sustainability report, and followed this up with a dedicated sustainability website (Interface, 2009). The information in Box 2 is drawn from it.

Box 2 Interface's sustainability performance

Interface can certainly talk the talk, but it is clear measurable evidence that counts. The evidence in some key aspects of environmental impact shows meaningful progress. Here is some evidence drawn from their sustainability reporting web pages.

Waste-elimination activities

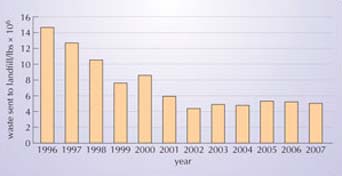

Interface began its journey to sustainability by focusing on the elimination of waste. It measures its waste in a ‘dollar value’ – something that helps attract the interest and commitment of employees (especially the all-important financial directors) and investors alike. By looking hard at trims and scraps, overuse of raw materials, inventory losses and/or labour to re-inspect or correct a defective product, it claims to have cut waste sent to landfills from carpet manufacturing facilities by 66% since 1996 (Figure 11).

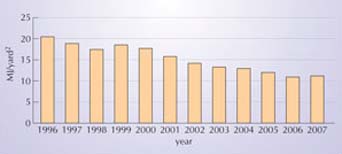

Another of the company's sustainability indicators is the source and quantity of energy it buys. It aims to: (1) decrease the use of non-renewable energy by increasing the efficiency of processes; (2) increase the use of green or renewable energy. The goal is less dependence on fossil fuels and, hence, reduced greenhouse gas emissions. Interface has reduced the total energy used at its carpet factories (per unit of product) by 45% since 1996.

Renewable energy in its plants takes the form of biomass (waste woodchip from a local company) and generating and purchasing green electricity (three Interface sites use photovoltaic arrays and four buy certified green electricity). Its long-term strategy is to increase both efficiency and use of renewable energy (Figure 12).

There are similar goals and progress in its approach to its whole manufacturing and marketing systems, including water use, the reuse of recovered materials (‘closing the loop’) and the replacement of petroleum based products. Its demanding sustainability strategy was seen as high risk in the 1990s, but the company has grown healthily, outperformed many of its rivals, and also been a leader in sustainable business practice. You can track its yearly progress on its website.

Even the brief account of Interface's story in Box 2 sketches out some of the following central messages of the business learns position.