Tay Bridge disaster

Use 'Print preview' to check the number of pages and printer settings.

Print functionality varies between browsers.

Printable page generated Saturday, 20 April 2024, 6:53 AM

Tay Bridge disaster

Introduction

This unit starts by giving an overview of the two main categories of disasters: disasters of natural origin and disasters of human origin. It then analyses the Tay Bridge disaster, which was caused by mechanical failure.

Inevitably, human factors emerge as important in many major disasters. They may involve the failure by engineers, designers or managers to recognise faults in safety-critical products, or managers overriding the design team for other reasons – such as keeping to a deadline or keeping costs within a predetermined budget. We cannot therefore neglect discussing such problems in failure cases.

One way of examining such events is by dividing them into two categories, those of natural origin, and those occurring to manufactured structures. The division cannot be enforced rigorously, however, because the one can cause or interact with the other. The great forces unleashed by natural effects can make a structure unstable and hence unsafe, or even destroy it entirely. Structures should therefore be designed to withstand such forces.

It follows immediately that designers need to know what magnitude of force to expect for the lifetime of their particular product. When structures such as ships, aircraft or spacecraft are made specifically to withstand extreme environments, they should be able to resist those forces safely.

Find out more about studying with The Open University by visiting our online prospectus.

Learning outcomes

After studying this course, you should be able to:

critically evaluate disasters and their causes, especially from mechanical or material failures

demonstrate the importance of systematic and rigorous analysis of disasters, so that future failures can be avoided or prevented.

1 Disasters of natural origin

1.1 Overview

Why are disasters important? They attract public attention because there is great loss of life, or because the event happened suddenly and quite unexpectedly, or because the accident occurred to a new project that had been regarded as completely safe. Certainly, the aspect of suddenness is one that features in many catastrophes, and indeed, it is this feature by which a catastrophe is defined.

Great disasters are always traumatic, especially for those who endure them and come through alive. They remain fixed in time and place, and are endlessly re-analysed for any clues as to their cause or causes with the quest for understanding, and for ways of forestalling or preventing future catastrophes of a similar nature.

Natural phenomena that can cause disasters are inherently uncontrollable, but yet attempts can be made to limit their effects on human populations by planning, or by engineering structures to make them more resistant to natural forces.

1.2 Earthquakes and volcanoes

The disasters that first come to mind are those where the earth itself changes in an unpredictable and sudden way:

earthquakes

volcanic eruptions

tidal waves

These natural phenomena are now known to be interconnected: earthquakes result from vast plates of the earth's crust meeting and moving against one another. Volcanic explosions, such as Krakatoa (1883) and Mount St Helens (1980) are also manifestations of activity in the earth's crust, where pools of hot magma build up under the surface and erupt explosively. This positive geographical correlation between zones of earthquake activity and volcanoes becomes apparent in places like the Mediterranean, the Andes and Japan.

Earthquakes themselves often involve movement of large bodies of rock, which, if occurring on the seabed, will create a sudden movement of the sea above and hence a tidal wave that propagates to land, often over vast distances.

Such phenomena are now well studied, and the magnitude of earthquakes is classified in terms of the Richter scale – after the Californian seismologist who devised the scale in 1935. The severity is described on a logarithmic scale from 1 to 9, as shown in Table 1. The scale is defined strictly by reference to a set of tables, using data such as the maximum lateral amplitude of the vibrations recorded by a pen on a moving graph and the distance of the listening station to the epicentre of the quake. The related Mercalli scale in Table 2 shows the effects of quakes on structures and people.

| Magnitude | Consequence (and some examples) |

|---|---|

| 1 to 3 | recorded on local seismographs, but generally not felt |

| 3 to 4 | often felt, no damage |

| 5 | felt widely, slight damage near epicentre |

| 6 | damage to poorly constructed buildings and other structures within 10 km |

| 7 | major earthquake – causes serious damage up to 100 km (recently in Taiwan; Turkey; Kobe, Japan; and California) |

| 8 | great earthquake – great destruction, loss of life over several 100 km (1906 San Francisco; 1949 Queen Charlotte Islands) |

| 9 | rare great earthquake – major damage over a large region over 1000 km (1960 Chile; 1964 Alaska, and west coast of British Columbia; 1700 Washington, Oregon). |

| Magnitude | Consequence |

|---|---|

| I | Not felt except by a very few under especially favourable conditions. |

| II | Felt only by a few persons at rest, especially on upper floors of buildings. Delicately suspended objects may swing. |

| III | Felt quite noticeably by persons indoors, especially on the upper floors of buildings. Many do not recognise it as an earthquake. Standing motorcars may rock slightly. Vibration similar to the passing of a truck. |

| IV | Felt indoors by many, outdoors by few during the day. At night, some awakened. Dishes, windows, doors disturbed; walls make cracking sound. Sensation like heavy truck striking building. Standing motor cars rocked noticeably. |

| V | Felt by nearly everyone; many awakened. Some dishes and windows broken. Unstable objects overturned. Pendulum clocks may stop. |

| VI | Felt by all; many frightened and run outdoors, walk unsteadily. Windows, dishes, glassware broken; books fall off shelves; some heavy furniture moved or overturned; a few instances of fallen plaster. Damage slight. |

| VII | Difficult to stand. Furniture broken, damage negligible in building of good design and construction: slight to moderate in well-built ordinary structures; considerable damage in poorly built or badly designed structures; some chimneys broken. Noticed by persons driving motorcars. |

| VIII | Damage slight in specially designed structures; considerable in ordinary substantial buildings with partial collapse. Damage great in poorly built structures. Fall of chimneys, factory stacks, columns, monuments, walls. Heavy furniture moved. |

| IX | General panic. Damage considerable in specially designed structures; well-designed frame structures thrown out of plumb. Damage great in substantial buildings, with partial collapse. Buildings shifted off foundations. |

| X | Some well built wooden structures destroyed; most masonry and frame structures destroyed with foundations. Rails bent greatly. |

| XI | Few if any masonry structures remain standing. Bridges destroyed. Rails bent greatly. |

| XII | Damage total. Lines of sight and level distorted. Objects thrown into the air. |

Engineers have made many positive contributions by designing structures, for example, which are now more resistant to earthquakes than previously (see Input 1, linked below). Nevertheless, there is much to be learnt about the geology of the earth both in the crust and below so that prediction of such natural catastrophes can be put on a more systematic basis than is possible currently.

Click 'View document' below to open Input 1

1.3 Hurricanes and storms

Of quite different origin are those disasters associated with the weather:

hurricanes

storms

tornadoes

floods

They too are interrelated, a hurricane being a vast area of low atmospheric pressure, which effectively grows into a giant vortex sometimes hundreds of miles wide (Figure 1). A storm is a smaller version of the same phenomenon, still associated with low pressure – a depression.

Both can be created when hot tropical seas give birth to a column of warm air saturated with water vapour. When such a column cools, the heat released by condensation of the water vapour further warms the air and provides a positive feedback loop for yet further growth of the storm.

Tornadoes are a more local phenomenon, a vortex of air spinning down from thunderclouds and, as yet, of inexplicable origin. Condensation of water vapour gives rise to growth of water droplets and hence rain, which in the tropics can be intense and long lasting from hurricanes or typhoons, so giving rise to floods of greater or lesser severity.

Although such phenomena are little understood, there are ways, at least, of classifying their severity, such as the Beaufort scale for wind speed (see Input 2, linked below).

Click 'View document' below to open Input 2

The hurricane that struck Galveston, Texas on 8 September 1900 is the worst natural disaster ever in the United States for the loss of life and destruction of property. It hit land during the morning and grew in intensity as the afternoon came, with winds of 84 miles per hour measured on anemometers at 5 pm. Beach homes had at this stage been washed away by giant combers from the sea. With nightfall, wind speed had increased to more than 120 mph, with a maximum of up to 150 mph. The winds only died down at about 10 pm, by which time most of the structural damage had occurred.

The US Weather Bureau and local meteorologists believed they could predict the track of the hurricane. They said the storm would veer away from the city, but they were wrong.

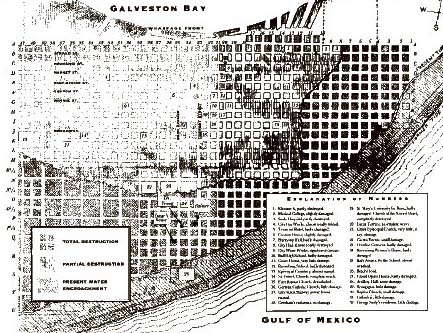

Half of the buildings in the city were totally destroyed (Figures 2 and 3) and between 6000 and 10 000 people lost their lives. The clapboard houses of the city were torn away by the winds during the event. The intense low pressure at its centre created a surge of the sea that inundated the stricken city, so compounding the disaster.

Question 1

Using the pressure data provided in Table C1 from Input 2, estimate the maximum wind pressure likely to be produced at the height of the Galveston hurricane. Either draw a graph from the data provided, or identify the relation between the two variables concerned by calculation.

Answer

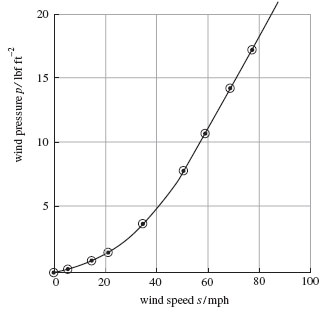

The relationship between wind speed s measured in mph at 33 feet and pressure p measured in lbf ft−2 can be estimated from Table C1 simply by drawing the curve of the one variable against the other, as shown in Figure 4 below.

It is clearly not a linear relation, so try the following equation.

Let p = k sn, a simple power law relation, a reasonable relation because pressure is zero when the wind speed is zero, and pressure grows faster than speed. k is a constant, hence

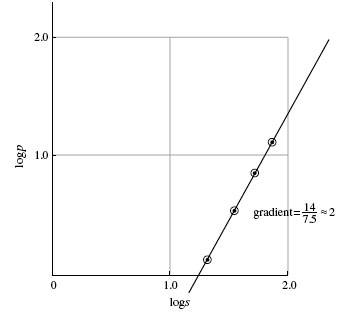

The value of n can be estimated by plotting log p against log s as shown in Figure 5.

The graph is a straight line, with a gradient of 14 / 7.5 or about 2 and the equation is thus p ≈ ks2.

Question 2

Using the relation developed in the previous question, estimate the pressure exerted by the maximum wind experienced during the hurricane at Galveston. Estimate the force exerted on a one-storey, low-cambered-roof, clapboard house with a side 50 feet long and 10 feet high.

Assume the wind acts at right angles to the windward side of the house. The side of the house is supported by 4-inch by 4-inch vertical posts spaced evenly at 2.5-foot intervals and inserted into the foundations. A post will snap off when subjected to a horizontal force of 1000 lbf ft−2 delivered 5 feet above foundation level. Predict the failure mode of the house.

Answer

Using Figure 5 developed in the previous question, then for a maximum wind speed of about 150 mph

so extrapolating onto the straight line on the figure gives

The force acting on a flat area a is given by

If there are vertical supports every 2.5 feet, there will be 21 supports along a 50 foot stretch of wall, so if the force is exerted uniformly, then the bending force per support will be about

As this exceeds the strength in bending of the support, the wall will be blown over, probably by breakage at the foundations. If the wall is made from overlapping slats, they may be stripped first if the connections between them are weak. The wall therefore falls in either case, the roof and other walls failing progressively.

As a direct result of the power of the winds, more than 2600 houses were totally destroyed (Figure 6), with an estimated 10 000 people made homeless. One reason for the high level of destruction was the low-lying position of the port, with most of the city built on an island off the coast.

Yet the port was reconstructed quickly from the remains of the old, although many protective measures were then incorporated into structures. Many buildings were raised seven feet to give greater height above the sea level, and a sea wall built to limit the effects of any future storms.

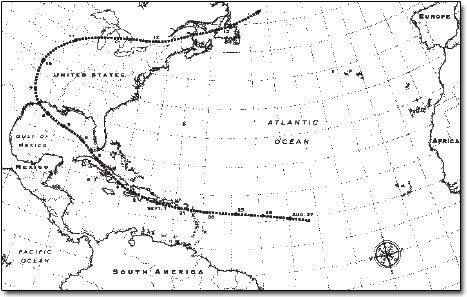

Prediction of storms and hurricanes is fraught with difficulty, but once a hurricane is formed, it can be tracked closely and warnings issued to communities likely to be in its path (Figure 7 shows the path of the Galveston hurricane of 1902). The prediction of an exact path is still a problem. Large areas are now cleared ahead of a detected hurricane in the predicted path, although a hurricane often behaves unpredictably.

The historical frequency of these weather phenomena varies in a way that is presently not well understood, although some climatologists suggest that storm frequency may rise, apparently due to global warming. The control of storms is correspondingly impossible, because of the sheer size of even small storms.

By contrast, disasters associated with manufactured structures or machines is potentially soluble, if for no other reason than that human beings can make rational choices about their design, maintenance and use.

2 Disasters of human origin

2.1 Overview

Catastrophes of human origin can be just as traumatic as those of natural origin, and are studied with even greater intensity for their causes. There are several ways disasters of human origin can be classified, depending on cause or size or origin. Another way of looking at them is by the kind of human activity – perhaps mining, fishing or transportation. Equally, disasters could be classified according to the kind of event that occurred during the accident – perhaps collision, sinking, fire or explosion.

Such events are frequently linked. One of the most well-known disasters in maritime history was the sinking of the Titanic in 1912. The sinking and total loss of the vessel occurred as the direct result of collision with an iceberg, as Input 3, linked below, relates.

Click 'View document' below to open Input 3

Transportation accidents are among the most serious of all disasters, simply because travel involves movement in a potentially hostile environment. Any collision, however small initially, can cause damage that can escalate from a small incident to a total catastrophe.

As Input 3 (above) relates, the subsequent Senate and Board of Trade enquiries led to big changes in the national laws of the USA and Britain, but also greater international collaboration between countries. The International Ice Patrol, for example, was born as a result of the disaster.

2.2 Transportation disasters

Movement of people and goods was one of the main outcomes of the industrial revolution in Britain in the late-eighteenth century, starting with canals, which were displaced gradually by railways. Industrialisation came through innovation in manufacture, especially the development of mass-produced materials such as cast-iron. While the material had been known and used since the Elizabethan period, it could only be made in small quantities by smelting iron ore with charcoal.

The Darby family of Coalbrookdale were the first to develop the use of coke in smelting ore. The coke itself was made by burning certain types of coal with a restricted supply of air, so that the carbon content was conserved, and transforming the coal into porous nodules capable of supporting a mass of material above. The coal was mined locally and the large quantities of iron that became available as a result of improved and larger furnaces using the new fuel, was cast directly into sand moulds to make domestic items such as cooking pots, grates, fireplaces, and stoves. Design with the new material culminated in the construction of the first cast-iron bridge across the Severn (see Input 4, linked below).

Click 'View document' below to open Input 4

2.3 Railways in Britain

The railway age started with attempts to make a steam engine small enough to be fitted to a wagon for hauling coal at collieries, the wheels moving on a wooden or iron rail for guidance. Improvements to the drive mechanism led directly to the Locomotion designed by George Stephenson, and the opening of the first passenger and goods service for the 27 miles between Stockton and Darlington in County Durham. It was opened in 1825 and was quickly followed in 1830 by a line between Manchester and Liverpool, but the opening saw the first railway fatality: local MP Mr Huskisson was run down by the locomotive Rocket.

Both railways were an immediate success, allowing raw materials and manufactures to be transported faster than by canal. Their popularity with the public was great, both for leisure and work.

The railway network expanded fast, although the greatest period of expansion occurred a little later, when railway mania took hold (see Input 5, linked below). The construction teams were most efficient when laying track on the level or along slight gradients, whereas a great deal of engineering work was needed for embankments or cuttings even where dips and hills were only moderate. Understandably, bridges over river valleys and estuaries were a challenge.

Click 'View document' below to open Input 5

2.4 Early disasters

Many of the earliest bridges were simply a wooden trestle type of construction, an efficient and easy-to-build structure, yet providing a secure and safe passage for heavy metal trains. Although we tend to associate such structures with the United States, they were in fact widely used in Britain in the early days of steam locomotion. However, they had a limited lifetime owing to rot, so were gradually replaced by wrought iron girder bridges, often laid on brick or masonry piers.

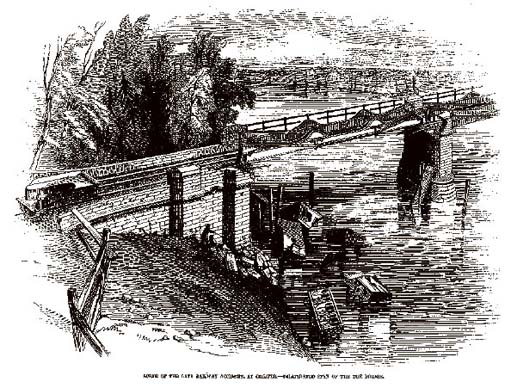

Designers frequently used cast-iron as a cheap alternative to wrought iron, especially as it had been proved in the bridge at Coalbrookdale. However, lack of consideration of the brittle nature of the material led to one spectacular disaster in 1847. A long bridge over the river Dee at Chester failed suddenly while a passenger train was crossing – the result is shown in Figure 8. The investigation is discussed in more detail in Input 6, linked below. Although the subsequent inquest cleared the famous engineer Robert Stephenson, he turned to wrought iron alone for his future bridges over the Conway and Menai Straits, and tested his materials with greater rigour than before.

Click 'View document' below to open Input 6

Collisions were frequent on the early railway system, mainly because of the lack of control of trains and what track they were on in the system. Failures attributable to engineering faults included numerous boiler explosions – largely caused by galvanic corrosion – and wheel or axle fractures (Table 3). A similar pattern of disasters occurred in the fast-growing rail networks in both Europe and North America.

A defining moment for the British railway system occurred some 32 years later, when the bridge over the river Tay – the world's longest bridge – collapsed in a gale while carrying a passenger train from Edinburgh.

| Date | Place | Railway | Description |

|---|---|---|---|

| 1830, 15 Sept | Rainhill | L & M | Mr Huskisson run down |

| 1840, 7 Aug | Howden | H & S | casting fell from truck |

| 1840, 10 Nov | Bromsgrove | B & G | boiler explosion |

| 1846, 1 Jan | Tonbridge | SE | bridge collapsed |

| 1847, 24 May | Dee Bridge | C & H | bridge collapsed |

| Southall | GW | broken wheel tyre, goods derailed | |

| 1849, 27 June | Hemerdon | SD (GW) | boiler explosion |

| 1850 | Wolverton | L & B | boiler explosion |

| 1860, 20 Feb | Tottenham | EC | derailment, broken tyre |

| 1861, 8 July | Easenhall | LNW | boiler explosion, Irish mail |

| 1862, 8 Nov | Westbourne Park | GW | boiler explosion |

| 1864, 5 May | Colne | Mid | boiler explosion |

| 1864, 9 May | Bishop's Road | GN | boiler explosion |

| Leominster | S & H | boiler explosion | |

| 1870, 20 June | Newark | GN | collision, broken wagon axle |

| 1870, 26 Dec | Hatfield | GN | derailment, broken coach tyre |

| 1873, 3 Aug | Wigan | LNW | high-speed derailment on points |

| 1874, 24 Dec | Shipton-on-Cherwell | GW | derailment from broken coach tyre |

| 1879, 28 Dec | Tay Bridge | NB | bridge collapsed in gale |

3 Tay Bridge disaster

3.1 Overview

The Tay Bridge disaster came towards the end of a period of intense development of the railway system in the UK. The bridge had materials that were well known. Cast iron was used for the columns and wrought iron for the trussed girders.

The construction of the bridge was, at the time, the largest single engineering project in Britain, the Tay estuary being about two miles wide near Dundee, and the bridge was the longest in the world.

In the shallower approaches in the estuary, conventional brick piers were used to support the trussed girders, and they survived the disaster in reasonable condition. A firm rock base to the river existed here, giving secure and reliable foundations. However, the critical part of the bridge lay at the navigable and deeper part of the river, somewhat closer to Dundee. Here the foundations were less secure, consisting of sand and gravel. This part of the bridge therefore had a lighter construction.

Where the estuary was navigable, part of the bridge had to have a greater height because of masted boats, especially for boats going to and from Perth, upstream of Dundee. Here, the line was built within a raised, trussed structure – the so-called high girders part of the bridge.

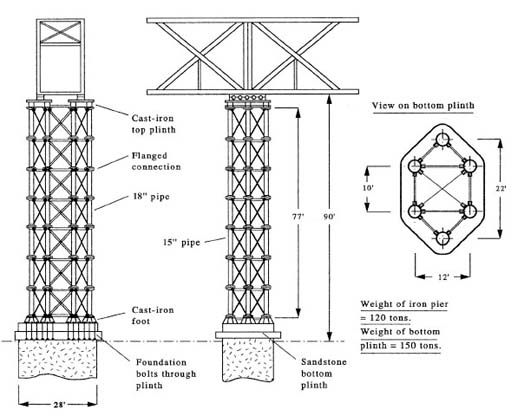

The chief engineer Thomas Bouch chose to use cast-iron columns bolted together to form the supports. Each support comprised six such columns mounted on 12 concrete and brick-faced platforms built on, and piled into, the riverbed. The outermost columns slanted at a small angle inwards – called a batter – so as to give an extra degree of stability to the piers. Each set of cast-iron columns was braced together by wrought iron tie bars attached to lugs designed into and integral with, the cast iron of the columns.

The stone foundations survive to this day, and are visible from the new Tay rail bridge, which was built quickly after the disaster alongside the old structure.

Much, but not all, evidence from the disaster that befell the Edinburgh–Dundee train passing over the bridge survives in various archives and some of this material will be presented here. In addition, detailed mechanical tensile tests after the disaster were performed by David Kirkaldy and were available to the investigators. The way the disaster was investigated was innovative. The information gathered included:

eye-witness testimony of the collapse;

many photographs of the remains, together with a scale model of the bridge;

many failed samples produced as exhibits at the enquiry;

mechanical tests of the materials of construction;

testimony from numerous expert witnesses.

The disaster had a major influence on the way bridges were built afterwards; in particular, the replacement Tay Bridge built alongside the failed structure, and the larger Forth Rail Bridge near Edinburgh. Steel was the main material of construction in the latter, with greater strength and reliability than cast iron. Bessemer steel, which had been available for some time, could not be used in the original Tay Bridge because of restrictive regulations.

This disaster is a good case study for examining not only the way the investigation developed and the forensic tools used, but also for the new light that can be shed on the causes of the failure using methods not available to, or not appreciated by, the Victorian investigators.

3.2 Background

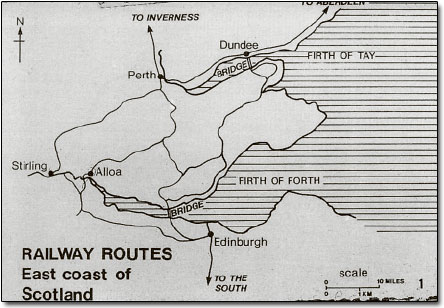

North of Edinburgh, in east Scotland, lie two great estuaries, the Firth of Forth and the Firth of Tay. The Firth of Forth begins at the ancient town of Stirling and runs 50 miles to the east, where it emerges into the North Sea. Edinburgh, the capital city of Scotland, is situated on the southern bank at the mouth of the estuary 30 miles east of Stirling (Figure 9). Eleven miles west of Edinburgh, at Queensferry, the firth narrows down to about a mile in width, but the water is still between 40 and 60 feet deep depending on the tide.

The Firth of Tay lies about 25 miles to the north of the Forth. It begins at Perth and runs east for about 25 miles until it meets the North sea (Figure 9). At this point, near Dundee, the Firth of Tay is 1.5 miles wide and is up to 80 feet deep.

The two firths have always been a major barrier to communications to and from Edinburgh, and this was especially so when the railways were expanding at a frantic pace. A passenger who wanted to go from Edinburgh to Dundee and perhaps on to Aberdeen, had to travel the long way round through Stirling and Perth, adding about 60 miles to the journey.

Alternatively, the passenger had to endure two ferry crossings, across the Forth from Granton to Burntisland, and across the Tay from Tayport to Broughty Ferry. The fastest boat train of the day left Waverley station at Edinburgh at 6.25 am and was timed to arrive at Dundee at 9.37 am, a journey time of 3 hours 12 minutes for a distance of only 46 miles at an average speed of only 14 mph. In bad weather, the ferries might not run at all; if they did, the hapless passengers would probably arrive cold and seasick. Freight traffic posed special problems because goods had to be offloaded at the ferry terminals.

The route was operated by the Edinburgh and Northern Railway. In 1849 it appointed a civil engineer, Thomas Bouch, to be their manager. Twenty-six years old at the time, he immediately set about improving the ferry service and by 1850 had built what was the world's first roll-on-roll-off train ferry. Bouch realised, however, this was only a stopgap measure: the real answer to the problem was to build railway bridges over the Forth and Tay.

In 1854, the E&N Railway was taken over by the rapidly expanding North British Railway. Bouch put his proposal for a pair of bridges to the directors of the NBR, but they dismissed it as ‘the most insane idea ever to be propounded’. In the long run, of course, the case for the bridges was overwhelming; but the chequered progress of the project gives a fascinating insight into the ruthless commercial politics of the railway age.

Eventually, on 15 July 1870, a Bill was passed by Parliament that authorised the construction of a bridge over the Tay. Bouch, by then an independent consultant, was appointed engineer to the new bridge (Table 4).

| Event | Approximate date |

|---|---|

| appointment of Bouch to E&N railway | 1849 |

| first train ferry across Forth | 1850 |

| bridge proposal put to NBR | 1854 |

| act passed to approve Tay Bridge | July 1870 |

| contract to build a bridge across the Tay | October 1872 |

| survey of estuary | December 1872 |

| start of site work | January 1873 |

| Wormit foundry at south end of bridge built | February 1873 |

| Hopkins, Gilkes & Co take over contract | July 1874 |

| accident in caisson on pier 54; 6 die | August 1875 |

| fall of main girder in storm | February 1877 |

| bridge finished and first train passes over | September 1877 |

| testing of bridge by Major-general Hutchinson | February 1878 |

| first passenger train passes over completed bridge | May 1878 |

| Queen Victoria rides over bridge; Bouch knighted with Bessemer | June 1878 |

| bridge collapses in gale killing 75 people | December 1879 |

| Board of Trade enquiry starts in Dundee | January 1880 |

| Board of Trade enquiry to London to hear expert evidence | April 1880 |

| final report to Parliament in London | June 1880 |

3.3 Description of the bridge

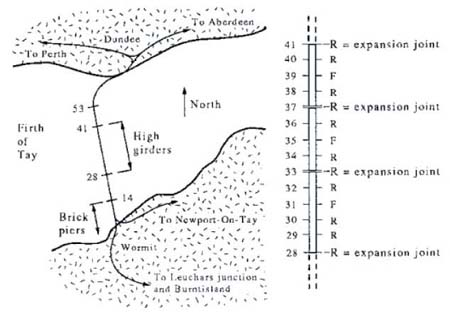

An outline plan of the bridge shows the main piers on which the bridge was laid (Figure 10). To allow shipping to pass up the Tay to Perth, a height of about 88 feet was required between the bridge girders and the high water mark in the middle of the firth. On the south bank, at Wormit, the land rose steeply to a height of about 200 feet, and this proved ideal as a jumping-off point for the bridge.

After leaving the bank on a short curve, the track climbed gradually at 1 in 490 until it reached pier 29 (pier numbering is shown in Figure 10). It then ran level to pier 36. After passing pier 37 the track fell rapidly at 1 in 74, until it reached the north bank at Dundee. At pier 53, the track entered a large, sweeping curve that took it alongside the bank and down to a height of about 40 feet above high water. The overall length of the bridge from bank to bank was over 2 miles, which at the time made it by far the longest bridge in the world.

Bridge girders

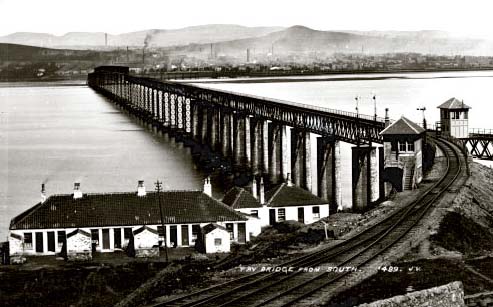

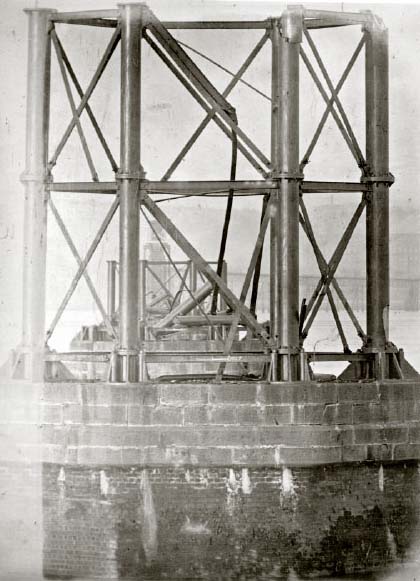

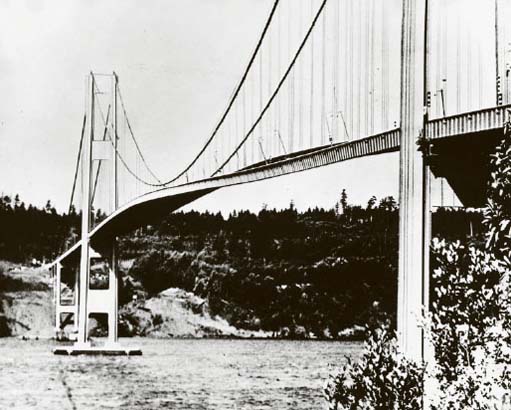

Figures 11 and 12, below, are photographs of the bridge taken from the south and north banks of the firth.

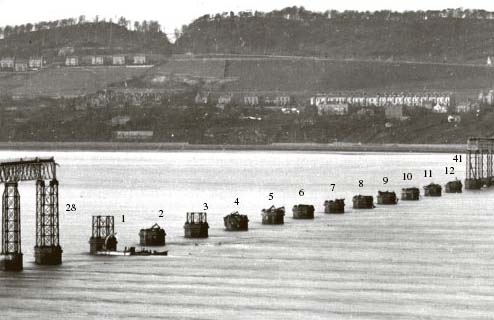

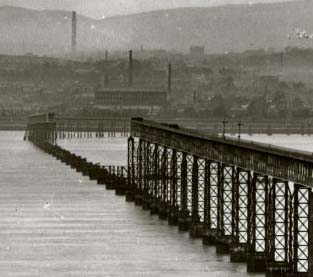

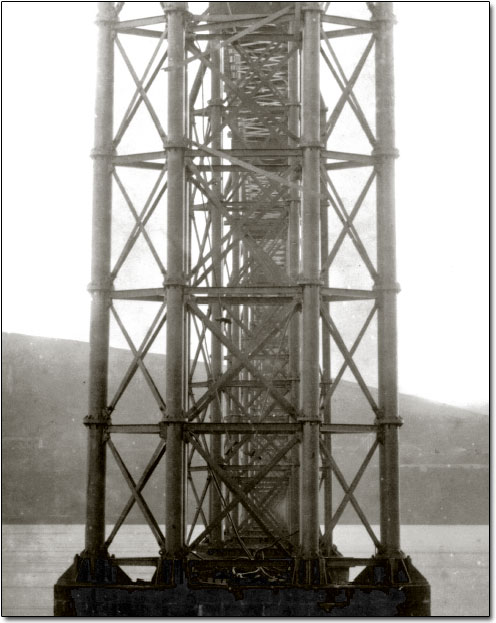

The girders of the bridge were supported on a total of 85 piers. The first 14 piers were made from brick and masonry, built up as a solid structure. The rest were fabricated from iron on masonry platforms, and by comparison, appeared rather insubstantial (Figure 11). Over most of the bridge, the track ran on top of the girders (Figure 12).

But between piers 28 and 41 the construction was different. This was the place where the navigation channel lay, and where the bridge had to have the full headroom of 88 feet. To achieve the extra height, the piers were extended to bring their tops up to the level of the tracks.

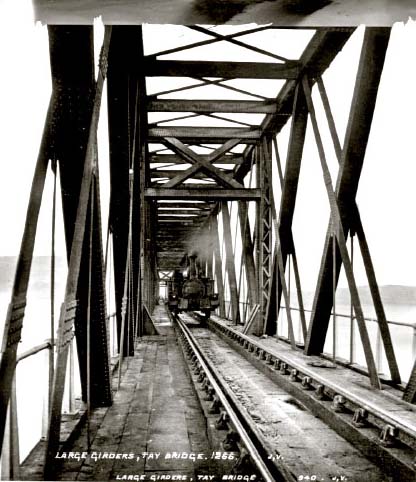

Thirteen spans of lattice-work box section were then placed end-to-end on top of the piers, and the track was carried on the floor of the box (Figure 13). The thirteen spans, the high girders, can be seen clearly in Figure 12.

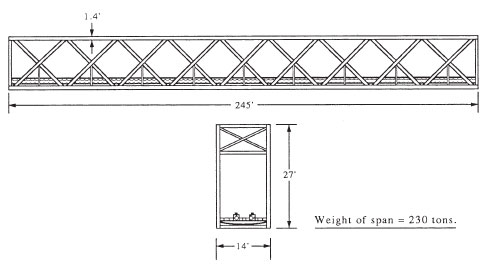

Made from wrought iron sections riveted together, a single 245-foot span weighed about 230 tons complete with track and wooden decking. As shown in Figure 10, the individual spans in the high girders were joined together into three continuous lengths, one of five spans, the two of four spans. The high girders were fixed at only three points to the piers (labelled F in the figure), roller bearings at the other piers allowed for thermal expansion and contraction.

The track was single, laid to the standard gauge of 56.5 inches and fitted with railings on the approach to the high girders. They would not have prevented the train toppling over the edge if it had derailed, however. A passenger would have felt more secure once the train had entered the high girders, although some complained about the drumming noise the open latticework set up as the carriages passed.

Figure 14 shows the side and end elevations of a 245-foot span from the high girders. The main dimensions are given in the Board of Trade (BoT) enquiry report, and details have been estimated from photographs taken for the enquiry.

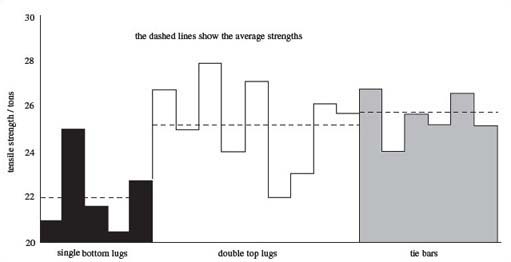

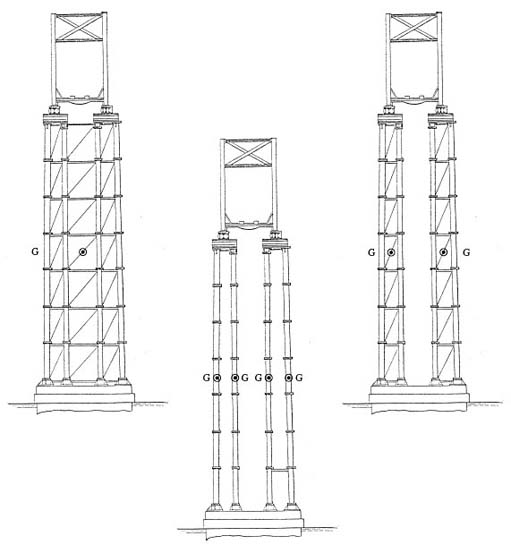

Construction of piers

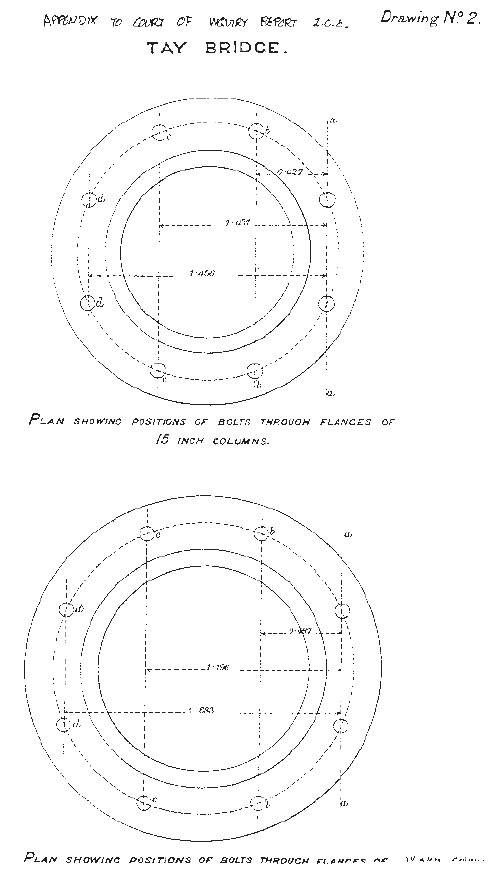

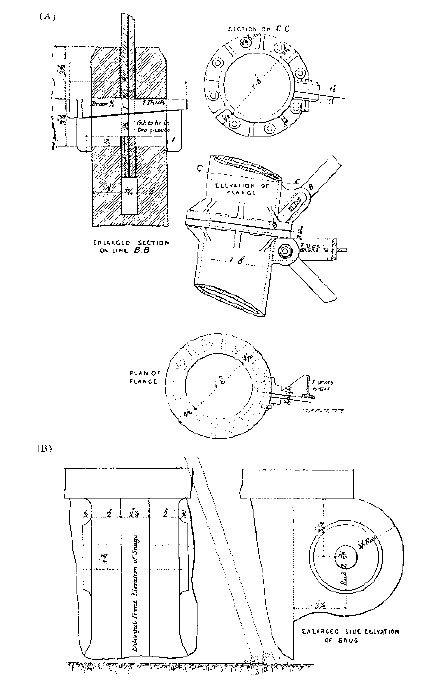

The dimensions and detailed construction of the cast-iron piers are shown in Figure 15. A single pier consisted of six columns of cast iron tied together by struts, bars and rods made from wrought iron. Each pier in the high girders section was built up by bolting together seven flanged cast-iron columns, giving seven tiers. The ends of the flanges were fastened together with eight 1.125 inch (1⅛) wrought iron bolts as shown in Figures 16 and 17, below.

The four columns, forming a rectangle in plan view (Figure 15), had an outside diameter of 15 inches and a wall thickness of 1 inch. The two outside columns had a diameter of 18 inches as shown in Figure 16.

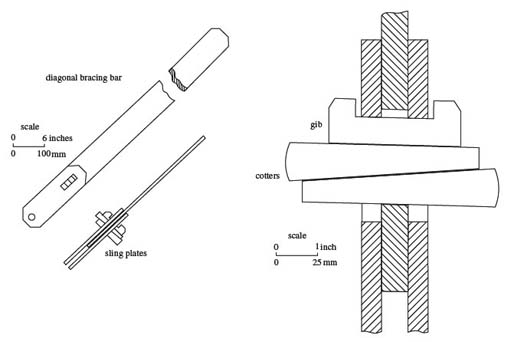

The bracing bars were secured to lugs cast as one with the column. The horizontal bars (referred to in this unit as struts) were made from channel section wrought iron and were secured at each end with two wrought iron bolts. The diagonal bars (referred to in this unit as tie bars) were made from iron flats with a cross-section of 4.5 × 0.5 inches.

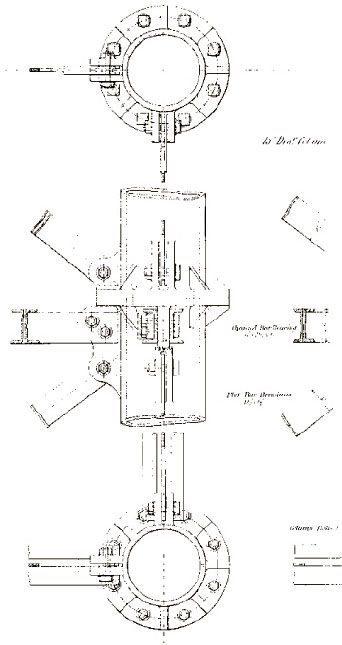

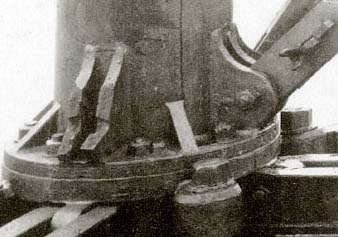

Each diagonal tie bar was held by a 1.125 inch bolt at one end and was jointed into two sling plates at the other. The sling plates were attached by another 1.125 inch bolt going through 1.25 inch (1¼) holes in the lugs. The tie bar could then be tensioned at the joint by two cotters (opposed wedges) hammered into a slot that also housed a gib (metal pad), as shown in Figure 18.

As a pier was erected, the inside of each column was filled with Portland cement, apparently to protect it against corrosion. The total weight of a pier complete with cement filling, bars and top plinth was about 120 tons.

3.4 Building the bridge

The contract for the bridge was won by the firm of Charles de Bergue, and a contract signed on 8 May 1871, whereby the contractor undertook to have the bridge ready for traffic in three years at a price of £217 000. In the event the bridge was opened on 31 May 1878, by which time it had cost £300 000.

Work started on the south bank of the Tay, with piers laid on to solid rock foundations. As the piers advanced into the estuary, foundations needed to be sunk onto the river bed, and caissons (cylinders of wrought iron) were lowered onto the bed, and the water extracted so that workers could excavate the bed itself.

As the alluvium was removed, the cylinder sank down to the bedrock, and was then filled with concrete and built up above water level to form the pier. A solid brick and masonry pier could then be constructed up to the level of the track. Unfortunately, the rock shelf on which the first 14 piers were built became deeper and deeper. A new method of building the piers was needed.

The original contractors were replaced by Hopkins, Gilkes & Co, although they kept the site manager, Arthur Groethe. The increasing depth of solid foundations was tackled by driving piles into the alluvium to give firm support for the piers, and the piers themselves were made much lighter.

Bouch changed the materials for the piers from solid brick to a cast-iron and wrought-iron space frame, a method he had used successfully in a previous bridge at Belah in the Pennines (see Input 7, linked below). The caisson on one such pier (no. 54) burst in August 1875, and six men were killed by the inrush of mud and water. By April 1876, construction had proceeded well with 76 of the 85 spans being built, so only 18 further spans were needed to complete the structure.

Click 'View document' below to open Input 7

Later, in February 1877, when the high girders were being lifted into position on top of the finished piers, there was another accident that should have served as a warning of the problem of high winds on the structure.

The two southernmost spans had been floated out on pontoons, and raised by hydraulic jacks ready to be lowered onto the pier heads. The girders were normally raised onto the piers at a low height, and the columns raised with the girders held above them by hydraulic jacks. They hung on metal pins supported by temporary columns five feet above the pier heads. The pins were moved into different holes until a girder was in place.

A gale suddenly sprang up as night approached, and at about 8.15 pm the girders were blown from their positions into the water below. The wind must have been strong, because temporary shacks in the girders used by the workers were blown away. One worker died, but the damage was repaired.

The bridge was first crossed by the directors of the NBR on 26 September 1877, and detailed tests conducted on its stability by Major-general Hutchinson in February 1878. He spent three days examining the bridge, finally testing its loading capacity with no fewer than six ballast engines running at various speeds across the structure. Vibrations were, he thought, not excessive, but he was not able to test for wind pressure. The bridge was opened to public traffic and a regular timetable implemented.

3.5 Sunday 28 December 1879

The morning of Sunday 28 December 1879 was quiet. When Captain Wright took his ferry boat, the Dundee, across the firth at 1.15 pm, he noted that the weather was good and the water was calm. The 4.15 pm crossing was just as uneventful, but the captain noted that the wind had freshened.

By 5.15 pm a gale was moving in from the west and the river, in the words of the captain ‘was getting up very fast’. The local shuttle train left Newport at 5.50 pm and arrived at Dundee station shortly after 6 pm. The passengers had had a worrying crossing. Their carriages had been buffeted by the growing force of the storm, and lines of sparks had flown from the wheel flanges under the sideways force of the wind.

The mail train from Edinburgh had left Burntisland at 5.20 pm, and by the time the local had arrived in Dundee, the mail had reached Thornton junction, 27 miles south of the bridge. The last station was St Fort, which lay in a small depression south of the bridge. The station staff collected the tickets of the passengers who were going on to Dundee. In addition to three men on the footplate of the locomotive, there were 72 passengers.

By 7.13 pm, the train had reached the signal station at Wormit. The driver slowed the locomotive down to walking pace so the fireman could take the staff for the single line from the signalman. Then he opened up the regulator, and took the train out onto the bridge and into the teeth of the westerly gale. The signalman returned to the shelter of his cabin, and sent the train-entering-section signal to his opposite number in the signal box at Dundee.

Disaster!

The train receded into the darkness and the light of the three red tail lamps grew dimmer. Sparks flew from the wheels and merged into a continuous sheet that was dragged to the lee of the bridge parapet. Eyewitnesses would later recall at the inquiry that they saw a bright glow of light from the direction of the train just after it must have passed into the high girders section, and then all went dark.

The train was timed to pass the Dundee signal box at 7.19 pm. When it failed to arrive, the signalman tried to telegraph the Wormit box, but to no avail. The obvious conclusion was that the telegraph lines had been severed where they passed over the bridge.

James Roberts, the locomotive foreman at the Dundee engine sheds, walked out over the bridge to investigate.

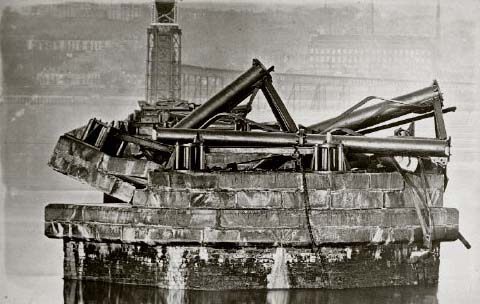

Although at times he was forced to crawl on all fours by the force of the gale, he eventually made his way to the end of the low-level girders (Figure 19). Further progress was impossible: the whole length of the high girders had disappeared into the river taking the train with it. Although steamers went out later that night, no survivors were found.

Question 3

At the time of the disaster, the wind was coming from the west and the high girders fell to the east. What does this suggest about the root cause of the failure? What effect, if any, would the train have had? What supporting evidence is there for your theory?

Some structural damage occurred in Dundee at about 7.15 pm, including loss of several chimney pots and at least one tree was blown over. What can be inferred about the wind speed at the time of the disaster?

Answer

One possible cause is lateral wind loading on the high girders, which would have pushed them downwind. The train would have offered additional resistance to the wind and this would have made the failure more likely. The main supporting evidence is the ‘sheet of sparks’ coming from the wheels of the train on the lee side of the train. It was presumably caused by the iron wheels rubbing against the rail, caused by the train being pushed over by the wind. The same effect was seen on the previous train to cross the bridge.

Using Table C1 from Input 2 to estimate wind speed shows that slight structural damage is characteristic of force 9 winds, although with a tree uprooted, gusting up to force 10 also probably occurred. With these limits, the lowest speed at the height of the storm was about 55 mph, with gusting up to about 63 mph. The train was lost at about 7.15 pm when this structural damage occurred. The actual wind speeds at the height of the train – about 88 feet above the water of the Tay – may have actually been slightly greater because the Beaufort estimates are based on a height of 33 feet, and wind speed generally increases with height above the ground or the sea.

4 Investigation into the Tay Bridge disaster

4.1 Condition of the bridge: an overview

An investigation was put into motion by the Board of Trade (BoT) as soon as news of the catastrophe reached London. Three commissioners were appointed to consider the evidence. They proceeded at their task with haste, knowing the country looked to them for an explanation of the accident.

Fifty photographs were taken of the remains of the bridge about a week after the collapse at the request of the BoT enquiry team.

The photographs are vital evidence of the way the bridge piers failed, and are remarkable for their high quality. Details are seen in focus both in the foreground and the background, indicating the pictures were taken with a small aperture on a large glass plate.

The photographer appointed by the commissioners was a local firm, Valentines of Dundee – later to become famous for its picture postcards. The pictures were recorded on large silver emulsion plates (6 × 4 inches) using long exposure times. The plates had very small and well-distributed silver chloride particles so that detail was recorded, detail that was transferred to the positive print made from the negative. As the resolution of the print was also high, it means a substantial amount of that detail is in the pictures, and which can apparently only be revealed by using a microscope directly on the prints.

Owing to their age and rarity (the BoT set kept by Dundee City Library may be the last complete set still extant), new computer technology has been used to scan the prints optically, and store the digitised images on compact disc. The memory needed to store digitised images is prodigious, and a large picture at a resolution of 600 dots per inch needs more than 40 megabytes.

Once digitised, the images can be enhanced in several ways. For example, the original prints show little contrast, but it can be increased in the digitised image easily by changing the grey scale of the pixels that are used to store the images on the computer. High contrast means specific details can be seen more clearly by the investigator against the immediate background. In addition, and provided high resolution scans have been made, the images can be magnified to reveal the hidden detail.

The highest magnification used on the Tay Bridge set is about 10 times the original size, so the virtual microscope is equivalent to a low-power optical instrument typically used to examine fracture surfaces of failed products.

Such digitised images from the BoT collection are shown in Figures 20–27 (Sections 4.2–4.4). A complementary set held in the Valentine collection at the University of St Andrews, Fife, has also been used for this unit.

4.2 An introduction to the Board of Trade photographs

It is important to bear in mind that these shots show the bridge remains in the state they were in just after the accident, and are almost exactly what the investigators would have seen when they inspected the bridge (see Input 8, linked below).

Click 'View document' below to open Input 8

The weather cleared after the storm, and the piers were examined in bright sunshine. The photographer took views from the four cardinal compass points. The north and south views were taken from the next pier along, while the east and west shots were taken on the pier itself. The latter are especially interesting, because they provide the nearest we have to close-up shots of specific broken components.

So what do the pictures show? The long shots show the section of high girders disappeared almost entirely (Figures 20 and 21), together with a close-up of the wrought iron girders from the top of the bridge lying in shallow water beside the stone platforms left standing (Figure 22). Those remaining platforms can be seen in perspective view in Figure 20, where they have been labelled for ease of reference, starting at the standing pier 28, and proceeding along the line of stone piers from pier 1 – two tiers left standing – through to pier 12. The final pier at the extreme right of the shot is the other pier left standing, on the north side of the firth, pier 41.

4.3 Photographs showing the detail: collapsed piers

Figures 23 and 24 present the east- and west-facing views of a collapsed pier, pier 5, which lay just ahead of the train before it was lost in the disaster. Figure 23 shows parts of two tiers of what was presumably the lowest part of the cast-iron pier on this platform. The columns point towards the east, indicating the lowest tiers fell in this direction during the collapse.

The reverse angle picture, the view looking west (Figure 24), shows the lower columns of this set of tiers, which at the right have broken at a flange. The parts are above one another in the picture. The columns are still held together, however, by their wrought iron struts – the double members that were horizontal in the original upstanding pier. On the other hand, many of the original diagonal single tie bars have broken away, and in some cases, become grossly deformed during the collapse. For example, there is just such a tie bar in the centre of Figure 24, which has been bent double. It indicates the material behaved in a ductile and tough manner during the collapse.

More bent tie bars can just be seen in the centre of Figure 23, hidden behind and between the columns. Other tie bars seen in Figure 23 appear partly intact and straight, and are still attached at their upper points.

The horizontal struts at the base of the pier are still intact, four being visible in Figure 24, running between the large flange castings bolted into the masonry platform. A similar broken base casting is visible at the right-hand side of Figure 23. There are jagged pieces of cast-iron pointing up from these massive base flanges, which from their sharp edges, must represent the edges of fractures in the lowest parts of the cast-iron columns. A bolt can be seen lying on the top of a column in both pictures: was it placed there by the photographer to act as a scale for the pictures?

There is a prominent round tie rod on the platform itself, one of which has an end connection (lower part in the centre of Figure 24) still attached. The component was one of the horizontal reinforcing rods, which crossed – either south-west to north-east, or south-east to north-west – from opposite columns in the original pier (see plan view in Figure 15). The end connection was made from grey cast-iron, and fitted at the column heads, between the lugs for the tie bars and struts (Figure 16). Figures 25 and 26 show similar views of the platform of pier 4 – south of pier 5 – which was the pier over which the train had just passed when the disaster happened.

Question 4

Describe the damage to pier 4, relating it in a systematic way to the component parts of the structure. Use the design drawings of the components in Section 3.3 to discuss your findings. Compare the overall appearance with the damage visible on pier 5, and compare the damage of specific components one with another.

Answer

Starting first with the east-facing view (Figure 25), there are three fallen columns that dominate the scene. They appear to have collapsed to the east, just like those on pier 5, and there is more evidence of the ductile nature of the tie bars.

There are at least six bent and distorted tie bars visible in the picture, the distortion varying substantially. The slightly distorted bar at extreme right shows an intact bolt hole, which must have connected the tie bar to an upper lug, because the gib and cottered joints lay at the lower end of all the tie bars (Figure 16). Most of the double struts appear intact and in place, although there are several that appear out of position, and could have failed.

The columns at right and left have an unusual structure at their upper ends, with a cast-in flange with numerous bolt holes. This feature is not seen in the specification drawings (Figure 16). The holes presumably gave variable positions for attaching the horizontal struts, although in both cases, only the top hole was used. The adjacent lugs have fractured cleanly across the section of the cast-iron lugs in both columns. The left-hand broken lug is just below the end of the ladder top seen at right in the picture. The large base castings appear bereft of upstanding features.

The view looking west (Figure 26) shows the bases of the columns from the previous plate, and the upper parts (lower in the picture) show the curious features (with what look like piano keys) seen in the previous picture, but now in greater detail. The overall appearance is of greater complexity, especially in the way the tie bars appear to be woven inside one another. Most are very distorted. The centre column shows a bare flange from the top of a column, with no brittle fractures evident.

A gib and cottered joint (see also Figure 18) can be seen (right-of-centre), just below the intact flange. It is a lower junction, because the joint is close to the base of the column (see also Figure 16).

One of the struts visible shows some slight distortion, but is otherwise intact. It shows an intact and crisp end (centre), suggesting that either the bolts or the lug failed. Although the platform visible in both plates appears rather bare, there do appear to be traces of small debris.

Overall, the nature of the damage to both piers 4 and 5 is similar, showing collapse of the lowest tier towards the east, as one would expect from the final resting place of the high girders (see also Figure 22). It is interesting to observe that the collapsed tiers shown in Figures 25 and 26 represent the lower parts of only one set of three columns from the original pier (see also Figure 16). The east-most set is presumably in the water to the east, near to the girders.

4.4 Photographs showing the detail: partly collapsed piers

There were only two piers that showed tiers still standing, piers 1 and 3, next to the south pier still standing (pier 28). They are important because the debris lying on the platforms is much reduced, giving clear views of the platform surface and the state of damage of the upstanding tiers.

Two views are shown of pier 3, a view from pier 2 (Figure 27), and a close-up of the lowest tier looking west (Figure 28). That the two views are of the same pier is easily confirmed by the common feature of the hanging cross tie rod, with one of the quadrant (quarter-round) fixing castings still attached to its free end. It can just be seen in Figure 28, to the right, behind the right-hand diagonal tie bar in the foreground of the photograph. It formerly reinforced the first and second tiers, and is suspended at one end from a junction between the two tiers (Figure 27).

What does the pair of pictures show, and what can they tell us about the way the failure may have occurred on pier 3? Figure 27 shows an apparently intact lowest tier, with one exception. That exception is the failed diagonal tie bars that were bolted to the column bases (right-of-centre). The corresponding members (bolted left-of-centre) are both intact. Indeed, the outer tie bars – on the corner faces – are also intact in both directions, while at least two of the tie bars on the opposite face are also intact. All the horizontal struts visible in the two figures are intact. The two failed tie bars hang down, and have fallen to the floor of the pier where their fractured ends rest.

4.5 Photographs showing the detail: broken lugs

The bases of the columns to which they were attached originally on pier 3 deserve closer inspection. Even at this scale, the two fractured lugs where the tie bars were formerly fixed are clearly visible at the right-hand and left-hand sides of Figure 28 (arrowed). The southern (left-hand) column base in Figure 28 is shown at about ×8 magnification in Figure 29, below, and it is now possible to see the fractures more clearly.

The lug originally comprised two wings standing proud of the column surface, an intact lug being seen in section at the right-hand side of the same picture. It possesses a round outer edge, which blends in a smooth curve with the upper surface of the column, and more abruptly with the bottom flange of the column pipe.

The joint consists of a pair of metal sling plates that enter the slot between the two lugs and fasten by a single bolt that passes through the plates and lugs. The same intact lug also shows the way the two plates were connected to the single long tie bar, with a gib at extreme right, and two cotters jammed into the slot (see also Figure 18). The only problem with this interpretation is there seem to be four parts in the slot: has the joint been modified? The cotters were split pins, deliberately opened to prevent them slipping out of the joint.

The way the southern lug has fractured seems clear (Figure 29): the lug has broken across the bolt holes. The fracture surfaces appear rougher than the immediate adjacent metal surfaces, and there are slight differences between the crack paths in each lug. The southern lower fracture surface appears substantially rougher than the other parts of the broken components.

The other interesting feature of the break is the profile of the bolt holes: they are conical in section, tapering from narrow outer diameters to wider inner diameters. It was common practice in casting to provide a taper so that the core that formed the hole could be withdrawn easily without damaging the mould sand. They cannot have been drilled, but must have been cast to shape in the mould. The corresponding break at the northern lug (at right in Figure 28) is very similar in form.

The broken southern lug can also be seen in cross-section in Figure 27, at the base of the third column from the right. The section torn away is a sector of slightly more than 90°, and the remains of the hole at its apex is just visible. A high magnification of the column base is shown in Figure 30, below, with the lug arrowed. Another broken tie bar appears to be lying on the stone platform.

4.6 Photographs showing the detail: debris field

The relatively clear platform of pier 3 is also visible in Figure 28. There are several pieces of shaped metal on the floor, at least one appears to be a bolt. A close-up of the floor, taken looking east, is shown in Figure 31. So, what are the fragments? At least three bolts are visible, but more significantly, there are nine broken lug ends. These are the pieces that correspond to broken lugs such as those in Figure 28 and are identifiable by:

a curved outer surface;

a bolt hole;

two shorter sides.

The two short sides must be the fracture surfaces, which originally were part of the complete intact lug. The curved surface would be the outer cast surface of the lug.

Several other metal fragments are more difficult to identify, but it is clear that lug ends are the most common metal fragments seen on the floor. As the broken lugs on the lowest tier can only have produced four such parts, we can infer the rest came from broken lugs on the upper tiers that collapsed during the accident.

Moreover, it is most likely the lug ends came from lugs on the north and south faces of the tiers, where the diagonal tie bars effectively held the two groups of three columns together. These so-called wind brace tie bars would have been stressed if there was any side-to-side (west-east or east-west) movement of the upper part of the bridge.

The other fragments comprise three part broken bolts, and a large bolt complete with its nut and two washers. There are also three nuts, two of which include parts of the broken threads they originally possessed. They could have come from either the flange joints, or the lug connections, and there is nothing to distinguish between the two possible origins.

4.7 Photographs showing the detail: damage to pier 1

The final example of a partly collapsed pier is pier 1, photographed from the base of pier 28 and shown in Figure 32. Fracture damage to the flange at the top of the second tier is visible on the east-most column (top right); a large chunk of metal has broken off. The southern column (right of centre) exhibits a matching fracture where the parts are still held in position by the wrought iron strut. Propagation of the same crack has also released the top lug, with the tie bar and strut still attached, so they hang in the centre of the pier.

The damage overall is more severe than in the case of pier 3, but it is still possible to identify the pattern of fracture to the principal components. The second picture of pier 1 is shown in Figure 33: a view of the platform looking west towards the western columns. The image has been made lighter and the contrast increased to highlight parts lying on the platform and their fracture surfaces.

Question 5

Summarise and explain the damage to the principal parts of pier 1 visible on Figures 32 and 33, above. Be careful to survey the picture systematically, including any interesting features that might help to clarify how failure of specific components occurred. Distinguish between wrought iron and cast iron as the material of construction for those various parts you include in your survey. Include a comparison of the damage here with that visible on similar parts of pier 3.

Answer

In addition to the damaged cast-iron columns at the top of the tier already mentioned, further damage can be seen at the base of the right-hand column (Figure 32). It is where a large piece of the wall of the column has spalled away to expose the cement filling. Such damage might have been caused by a brittle crack running up from the base flange, itself initiated by bending of the column to the west.

The same movement could account for the damage to the top of the same column, but it cannot explain the damage to the top of the adjacent column (second from right in Figure 32), which was probably caused by bending of the higher columns to the east.

Similar contradictory comments apply to the tie bars, more having failed than in pier 3. Starting with the centre bracing structure, the lower part shows fracture of both of the east-facing tie bars, with the west-facing ones intact – just like pier 3. They have both fractured at the base lugs. The same is true of the tie bars in the tier above, with the added problem of the fall of the front bar with the strut above due to the flange fracture already noted.

Some of the other diagonal tie bars have broken as well, all of which appeared intact on pier 3. Two are seen in Figure 32, one at the upper tier at left, the other in the section of the structure diametrically opposite, at lower right. As in all other cases of tie bar failure seen in both piers 1 and 3, failure has occurred by brittle fracture of the lower single cast-iron lugs.

Turning to Figure 33, one common feature can be identified immediately, it is the end of the hanging tie bar. It is seen left-of-centre in front of the column, and the end is clearly visible. It is a standard gib and cotter joint attached to a pair of sling plates, and the bolt is still in place within the final holes. It can only have failed by fracture of the pair of lower lugs on the tier above. The lowest tie bar has been moved, presumably by the photographer: it is the tie bar at left in Figure 33. It is resting on the platform floor in Figure 32, but propped against the lower strut in Figure 33.

Figure 33 shows great similarity with the analogous shot of pier 3, especially with the two broken lower lugs and the debris field. The fracture surfaces appear very similar in shape, and there are several lug ends on the floor. There are also bolts and what seem to be cotters among the debris. Overall, the damage is similar, arguing for a similar failure mechanism in both piers.

4.8 Photographs showing the detail: standing pier 28

The final part of the survey deals with the two standing piers connected to the lower girders left after the high girders section fell during the disaster. The whole of pier 28 is shown in Figure 34, and two close-ups of the columns are shown in Figures 35 and 36.

Adopting the same procedure as we have used already, we will focus attention on the diagonal tie bars, although other damage must be examined for its relevance to the failure. In fact, it is the collateral damage that ought to be discussed first because both standing piers show damage that probably occurred towards the end of the collapse rather than at the beginning.

While Figure 34 is a useful starting point for the survey, it is important to see the pier in perspective. It is shown from two entirely different angles in Figures 20 and 21. That some damage was caused when the high girders were wrenched from the pier seems evident from examination of the top of the pier in Figure 34 (bent diagonals in the high girders section), and Figure 20 shows a gap between the girders and the top of the pier. With careful inspection, Figure 20 shows some of the bracing diagonals not in the critical north or south faces have also been broken. The cross braces facing the camera in Figure 34 show substantial damage, although there appears to be little damage to the braces on the corner faces.

The close-ups in Figures 35 and 36 help to clarify the situation. There is a large pile of debris on the platform, with bigger lumps of metal than in the case of piers 1 or 3. If it is debris that has fallen from the very top, it could have created substantial damage in the fall. Most of the cross tie rods appear hanging down in the centre section, and were probably broken by such a fall.

The top of the pier shows great damage (Figure 36), including three broken struts and one of the top diagonal tie bars has actually been bent double. The latter could have been caused by a large girder turning in its fall, and the strut just below shows a severely bent portion at its far end, which would support this suggestion.

Many of the tie bars below are broken at their lower single lugs and are hanging free. Indeed, the damage extends down to the lowest tier. One of the lowest diagonal tie bars is out of position – judging by the irregularity in pattern of the receding tie bars. Most of the east-facing diagonal tie bars on both sides of the centre of the pier appear to be broken at their lower lugs.

So, what happened at this pier? The girders were supported here only by resting freely on a roller bearing plate, and they were not fixed against lateral movement (Figure 10). It is known the girders remained substantially intact during and after the fall (Figure 22), and must have been wrenched sideways from the standing pier. As they were pulled off the pier, they pulled other parts of the structure off, which fell vertically and caused much of the collateral damage seen in Figure 34. This would probably have included the cast-iron rollers and the plate on which they rested on the columns very near the top of the girders (Figure 37).

The suggestion is reinforced by examination of the north pier, where even more collateral damage has occurred. It had a similar structure with a roller bearing plate, and most of the centre section supports were destroyed. Nevertheless, the damage to the tie bars and struts shows the connections to the columns were the weakest, no matter how that damage was caused. Most have failed by fracture of lugs, the connections cast into the structure of the columns.

4.9 Survey results

We have inspected some of the remains of the collapsed bridge using the set of photographs taken shortly after the disaster for the official inquiry. It is important to emphasise that the pictures form only a small part of the total of fifty, but those chosen were selected to give the clearest evidence of the failure modes in the cast-iron piers that supported the high girders. They are by the far the best real evidence to rely on to understand how and why the structure failed.

It would have been better to have the actual cast-iron lugs or even columns that failed, but they have apparently been lost irretrievably. Even if some had survived, however, there could be no guarantee of their provenance: exactly what pier and tier they came from, and so on. The pictures, on the other hand, show us the failed components almost exactly as they were in situ a few days after the accident. You can be confident the evidence is fresh and intact from interference – apart from some components perhaps being moved a little by the photographer.

We saw from those pictures that the wrought iron struts and tie bars were generally tough and survived intact, despite gross distortion having occurred in some cases. The cast iron survived less well owing to its brittle behaviour in tension, brittle cracking occurring at the flanges and lugs of the columns. In particular, the single lugs at the bases of the columns appeared particularly susceptible to fracture across the bolt holes when tensioned by the tie bars.

The evidence from piers 1 and 3 was especially striking, with fractured bottom lugs facing east and some nine lug ends scattered over the floor of the platform. There was supporting evidence for lower lug fracture in the large debris piles on piers 4 and 5, as well as the centre part of pier 28, one of the two standing piers left after the accident. Other lugs could have failed: a pair of upper lugs being seen on the collapsed columns of pier 4, columns of different form from those specified in the original designs of the bridge (Figures 14–18 in Section 3.3).

Although we have examined only two piers where destruction was total, they show only columns from the western set of tiers were still present on the piers. Those columns fell towards the east and they remained attached together, probably falling as a group. Presumably, the eastern set of three columns was pulled over into the water to the east of the piers, where the intact high girders were found.

4.10 High girders and the train

Divers found the high girders lying on their sides in the shallow water of the river bed a short distance away (Figure 22), within which the almost intact remains of the train itself was found. No bodies were recovered because they had all been washed away by the river or tide. Although bodies were recovered in the months that followed, some 29 victims were never found.

Most of the train was lying inside the fifth span of the high girders, counting from the south side left standing (Figure 38). The horizontal distance between the girders and the edges of the plat forms varied between 16 feet and 51 feet; the fifth span lay between 21 feet and 39 feet from the adjacent platforms. As the piers were 88 feet high, they cannot have simply toppled over, but must have collapsed in a more complex way.

When the locomotive was raised from the river bed it was found to be little damaged, externally at least, and the regulator was fully open, the reversing lever was in the third position from mid-gear and the brakes were fully off. This is the normal position for the controls when an engine is up to speed, and the driver could therefore have had no warning of the impending disaster he faced.

On further investigation, the engine was found to be little damaged, and after repair it was later to return to service, being nicknamed The Diver. Most of the damage was confined to the sides of the train, being most severe to the carriages, which were made from wood. The last two carriages had been reduced to matchwood. The axles of the brake van and the carriages were all bent.

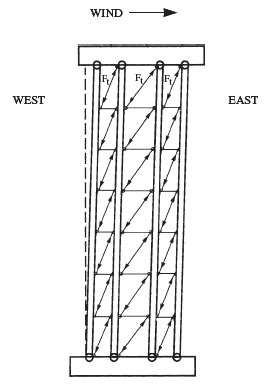

4.11 Model for pier failure

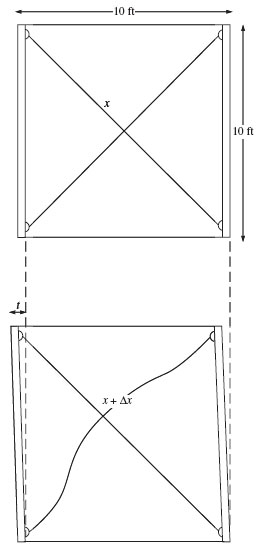

Figure 39 shows a simple model to explain the failure of the piers. The lateral wind loading on the top of the pier bends to shear the pier from a rectangle into a parallelogram. In turn, this stretches the tie bars and also strains the bolted joints at the top and bottom of each column.

You will notice the tension induced in the bars by the stress is shown in the tie bars as you might expect if they were all equally loaded by the tilting. The tension load will, however, be in addition to that already present from tightening of the joint when the bridge was built.

The second point is that the greater part of the load will be experienced by those tie bars directly in line with the direction of stress, the wind bracing tie bars aligned on an east-west axis. They are the set of tie bars in the centre of the pier.

The induced tension in the outermost tie bars (corner faces) will be somewhat less because they are aligned at an angle of about 45° to the east-west axis of each pier.

The inner set of tie bars aligned along the axis of the railway line should experience little or no stress because they are at right angles to the side-to-side movement of the bridge.

There should also be little or no tension in the horizontal struts if the entire structure distorts. Unlike the tie bars, they cannot be pre-tensioned because they have no gib and cotter joint. Indeed, they are designed to act in compression rather than tension. Any overall lateral distortion of the pier will lead to twisting at their attachment points however. They are attached to the top double lugs by two bolts, which should give extra security against twisting provided the joint is tight and there is little play between the bolts and the holes in which they sit.

The horizontal tie rods that cross diagonally within the pier are also unaffected by tilting of the pier. That is, they should not be tensioned by overall distortion of the pier shown in Figure 39. As the wind loading is increased, eventually the bracing tie bars and bolted joints will fail and the pier will collapse to the eastern side of the bridge.

Question 6

Examine the visual evidence shown in Figures 23–36 (see Sections 3.3, 4.4, 4.5, 4.6, 4.7 and 4.8) and identify features you think support the simple tilting model. Can you think of any alternative failure mechanisms that are consistent with the evidence?

Be cautious in your interpretation of the remains, because once a pier has started to give way, subsequent stages in the collapse may be highly unpredictable.

One way to explore further the simple theory is to examine a single cell of the structure, as shown by the diagram in Figure 40. The cell is defined by the two columns on either side and the two horizontal struts, with the pre-tensioned diagonal tie bars running from corner to corner of the cell.

Answer

As is usual in such cases, the problem is essentially one of distinguishing between damage caused by the collapse, and damage that led to the collapse. Support for the theory of collapse to the east comes from inspection of several key pictures from the BoT collection.

The first set of pictures from the totally collapsed piers 4 and 5 (Figures 23, 24, 25 and 26) show the west-facing columns fell almost as a group to the east. The two east-facing lugs (left- and right-of-centre in Figure 24) are broken through the bolt holes, and the columns themselves have broken behind the lugs to leave sharp projections. Those broken lugs could support the theory, but further corroboration is vital. The similar set of base lugs on pier 4 lie beneath the fallen columns (Figure 26), and so may have been further damaged during the final stages of the collapse.

Figure 27 shows the two broken diagonals facing the east, which would have broken from their lugs when pier 3 leaned over to the east. The upper tiers of pier 3 sheared away at the flanged joints to leave the lowest tier only. Figures 28, 29 and 30 show the broken lugs on the east-facing diagonal tie bars, a failure mode that appears to be a widespread problem in the structure.

Similarly, Figure 31 shows nine lug ends that have fallen to the floor of pier 3. They cannot all have come from the lowest tier and it is tempting to suggest they came from east-facing tie bars higher up the pier as the entire pier became unstable. As they lie to the east part of the platform, they may have been thrown here by elastic recoil from the column bases higher up the pier.

Figure 32 shows more complex damage on pier 1, but there are clear parallels with pier 3. All east-facing lugs on the centre part of the two tiers have broken, so leaving the tie bars swinging free, although some of the west-facing tie bars on the outer parts of each set of triangulated columns have broken.

This suggests at some stage during the collapse, the pier may have swung to the west before the top set of tiers fell to the east. The idea seems to gain some support from the presence of a large spall at the base of the right-hand column in Figure 32, perhaps caused by the structure swaying to the west, because the spall faces east. Figure 33 shows the broken lugs on the platform, further supporting the idea that the single base lugs were of low strength.

The standing pier 28 (Figures 34, 35 and 36) shows collateral damage probably caused in the final stages of the collapse when the high girders were pulled off the pier. Some of the damage on the centre part of the pier may, however, have been caused at an earlier stage in collapse. It is difficult to see, for example, how some of the east-west tie bars could have been damaged by fall of debris from the top of the pier because the struts above are intact (for example, the lowest east-facing broken tie bar on the bottom tier – a little out of alignment, is bottom of Figure 35).

So there is support for the theory from the visible remains, although collapse of the piers was more complex than the simple theory suggests. An alternative hypothesis is that tilting occurred in both directions before the final critical event. In other words, tilting may have occurred to the west as well as to the east, that is, the bridge oscillated.

Question 7

The simple tilting model has ignored the trailing diagonal tie bars, which are compressed as the pier becomes a parallelogram. Is this reasonable? To help visualise the situation, sketch the tie bars using Figure 40 as the model. Identify any supporting evidence in Figures 23–36 (see Sections 3.3, 4.4, 4.5, 4.6, 4.7 and 4.8) and specify any backlash possible in the cottered joint (Figure 18).

What will be the effect of tilting to the west on the diagonal tie bars?

Answer

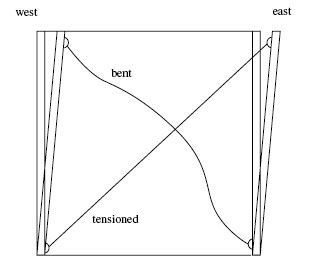

The diagonal tie bars have a section of 2.25 square inches (Figure 18). In axial compression, the diagonal bars will easily buckle (see Figures 41 and 42, below) and will not be able to support an appreciable compression load. The assumption is therefore reasonable.

In addition, there will be some slack to be taken up in the bolt holes at each end and also in the cottered joint. With reference to Figure 18, note that the cottered joint can move by approximately 0.5 inch in compression before it can lake any compressive load – so there is 0.5 inch of backlash in the joint. Supporting photograph evidence is available in the form of badly bent and buckled diagonal bars (Figures 24, 25 and 26).

Tilting the pier to the west (Figure 42) will have the opposite effect. That is, the tie bar with its lower lug facing west will be tensioned, while the other tie bar will be compressed and hence buckle under the load after taking up the slack in the gib and cotter joint.

5 Board of Trade enquiry into the Tay Bridge disaster

5.1 Overview

The enquiry team set up by the Board of Trade, and sitting in Dundee Court House, held an initial session lasting several days starting on Saturday 3 January 1880. There were three members chaired by Mr Rothery, Commissioner of Wrecks. The others were Colonel Yolland, the Inspector of Railways, and Mr W H Barlow, president of the Institute of Civil Engineers, and a distinguished practising civil engineer.

Henry Rothery was a mathematics graduate but trained as a barrister. He had been appointed in 1876 as wrecks commissioner. Cases he gave judgment on included fires at sea on colliers, and ways of stowing grain on ships to maximise stability. Colonel Yolland was a royal engineer who also had mathematics training, and had worked at the Ordnance Survey in the Tower of London. He had become chief railways inspector in 1877.

They were assisted by counsel for the enquiry and the North British Railway and other parties involved with construction of the bridge.

In all, they heard 121 witnesses and the final reports were delivered in the remarkably fast time of six months. The magnitude of the disaster and the shock to the railway system may explain the speed of the enquiry, but it was also essential to learn the design lessons for future bridges.

5.2 Eye-witness testimony

Their first main aim was to question local witnesses, including several who claimed to have seen the fall itself. One especially impressive eye witness was Alexander Maxwell, who lived on Magdalen Green, near the north end of the bridge. He was examined by Mr Trayner, counsel for the enquiry:

942. You are an engineer? – Yes

943. You live with your father, who is an ex-baillie of this town at Magdalen Green, do you not? – I do

944. I believe it is immediately to the north of the bowstring girder? – Yes

945. On Sunday evening, the 28th of December, do you remember that there was a great storm? – Yes