4 Engineering for products

The previous sections gave you a broad overview of engineering, looking at historical development, the processes of design and designing, and the environment in which engineering takes place.

In this section you are going to study how designs are turned into physical products: the resources, materials and methods used, and the set of activities that goes under the heading of 'manufacturing'.

Any design is only useful if it can be made into a product. Remember that an invention is only patentable if it is capable of being manufactured. So there has to be a way of making it, using materials that have the required properties and processes that produce the required product at a reasonable cost. This, in effect, is simply restating that the way you design a product, the materials you choose to make it from and the manufacturing processes you have to use are all interconnected.

Let's first consider what is meant by the term 'manufacturing'. You probably have a general feeling for it already. The word 'manufacture' derives from two Latin words: manus (meaning 'hand') and facere (meaning 'to make'). We generally think of manufacturing taking place in a 'factory': an abbreviated form of the eighteenth-century word 'manufactory', made up from those Latin words. So manufacturing applies to artificial products: it does not apply to natural products that grow on the surface of our planet, or that can be found in the Earth's crust or in the atmosphere. On the contrary, such products are the source of what we call natural or physical resources , many of which are starting points for manufactured items.

Such resources are also often called raw materials , but this term is more generally used to describe the input of any manufacturing process. Similarly the term product can be used to describe the output of any manufacturing process. (Of course 'product' is widely used nowadays to cover many types of service as well as physical products but those are not our concern in this section.) So, crudely, a raw material is anything that can be turned into something else, and the something else it is turned into can be called a product. A mining company takes its raw material directly from the Earth's mineral resources. To such a company, iron ore is a product. An iron producer operating a blast furnace uses this iron ore as a raw material and smelts it into a new product, pig iron, in a blast furnace. This pig iron is either allowed to solidify and sent on to another works (or 'foundry') or else kept molten and fed to a steel works. The output product from the blast furnace thus becomes the main raw material for the foundry or the steelmaker. The steelmaker turns the raw iron into steel sheets or bars. These steel sheets and bars then go on to become the raw materials for other manufacturers producing the enormous variety of useful products we see all around us, ranging from car bodies, railway tracks, domestic white goods (washing machines, refrigerators, etc.), to ultra-thin syringe needles, paper clips, and every conceivable item that contains steel.

Such manufacturing chains are an integral feature of practically all of these sorts of products that our society demands. It matters little whether it be nylon stockings, a plastic moulding for a roof gutter, a child's toy, a tube of adhesive, a high voltage electrical insulator for overhead power lines, a spark plug, or a grinding wheel. Every manufacturing chain can be traced back to some natural raw material that has to be put through several, often many, different processes before the desired product is ready for sale in its end market.

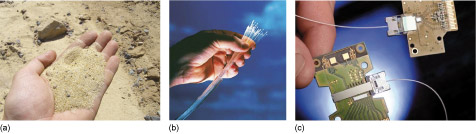

The majority of optical fibres are made from silica (silicon dioxide or SiO 2 in chemical terminology), which is the major constituent of sand. Purified silica is extracted from sand. It is often chemically modified to give specific optical properties and is processed into individual fibres that are then assembled into the fibre bundles – cables – which are fast becoming the main channel of terrestrial communications networks (Figure 52).

Sand is the raw material for the production of fibres. Fibres are the raw material for cables. The network installers buy and use the cables to build their networks. For each part of this chain, every person or organisation involved up until the final user will consider themselves to have suppliers of raw materials and consumers of their products.

Activity 31 (exploratory)

All products require raw materials in some form. Choose two or three items from the following list of manufacturing activities and make a list of the raw materials you can identify for your product. Think in terms of the input materials to the process, rather than the original resources.

- a.The manufacture of ammonia.

- b.The manufacture of ballpoint pens.

- c.The manufacture of copper pipe for central heating systems.

- d.The manufacture of loaves of sliced white bread.

- e.The manufacture of PCs.

- f.The manufacture of Open University printed units.

Answer

One thing you should have noticed from this activity is that some products, such as copper pipe, consist of just one material that is simply shaped into its finished form. Others – ammonia and bread – start with several raw materials that undergo chemical change to create a single, coherent item or substance. And others still, such as the PC, are assemblies of several components made from quite different materials.

Some raw materials are easier to identify than others.

- a.Nitrogen and hydrogen.

- b.Up to four different sorts of plastic for the barrel, lid, ink tube and plug; brass for the ball holder, tungsten for the ball.

- c.Copper, probably as ingots that can be drawn into rods and then into pipes.

- d.Flour, water, yeast (plus additives such as the vitamins that were removed from the flour and so-called 'improvers'), plastic film or waxed paper for the wrapping, printing inks, adhesive tape for the closure.

- e.Manufacture of PCs is very much an assembly job, so the raw materials are all the internal components, the housings, the mechanical connectors, the connecting leads etc.

- f.Paper, card, staples (or adhesive) and inks, obviously, but do you count the intellectual and creative efforts as inputs?

Activity 32 is another exercise in choosing the right material for the job but this time taking account of the form in which that material is supplied. You may feel that picking the right match is ridiculously easy in the cases given. But I want you to take a few minutes to summarise why the other candidates are not suitable. This elimination of candidates is going to become an important aspect of your decision-making about manufacturing routes during the section.

Activity 32 (self-assessment)

List the requirements of each of the applications (a)–(c) and then match it to an appropriate material/product from (i)–(vii). Very briefly summarise why each of the other options (i)–(vii) is unsuitable.

- a.Rope for mountain climbers.

- b.See-through door panel for an electric cooker.

- c.Prefabricated roof trusses for a medium-sized house.

Candidate materials and form:

- i.High tensile strength steel wire.

- ii.Sawn, kiln-dried timber planks joined with steel nails.

- iii.Moulded PVC plastic with black colouring.

- iv.Plaited nylon fibres.

- v.6 mm thick toughened glass sheet.

- vi.Thin-walled copper pipe.

- vii.Perspex (transparent, hard) plastic sheet.

Answer

- a.Rope for mountain climbers. This matches with (iv) plaited nylon fibres. (i) steel wire would be far too heavy, might rust and would be difficult to grip. The other options are simply the wrong shape.

- b.See-through door panel for an electric cooker. This matches with (v) the toughened glass sheet. Of the other options, only Perspex is transparent, but this would soften and melt at oven temperatures.

- c.Prefabricated roof trusses for a medium-sized house. This matches with (ii) sawn, kiln dried timber planks joined with steel nails. Again, most of the other options are in the wrong form. Try nailing the other materials!

One thing that distinguishes humans from the rest of the animal kingdom is the ingenuity to devise tools and use them to achieve a purpose. The component parts of the large machines that can be seen in manufacturing plants are made by other machines and these in turn are made by others. They are all 'tools', and one tool is necessary to make another; in other words, all tools are themselves manufactured products. Indeed, most products that are manufactured have evolved from what has gone before, and all stem from the natural materials and resources on the Earth. The challenge to the engineer's ingenuity is to use these resources to the advantage of society. This can be done by understanding the properties of the natural materials and other materials that can be produced from them, before converting these into useful objects. Doing this efficiently and economically, with minimum waste of energy and materials is what successful manufacturing is all about.

Indeed, as you will see while working through this section, manufacturing is about much more than just choosing the right material in the right form. If a manufacturer concentrates just on the processing methods for converting materials into components, there is the risk of taking for granted things like the supply of raw materials to the process, the power consumed by the machinery, and the removal of finished products and waste. These are often seen as 'someone else's job'. There are circumstances when this approach is adequate. But engineers should be just as concerned about how to supply the process with materials at the right rate and cost, and how to deliver the products to the next process or to the customer at the right price. Only by doing so can they recognise and respond to important changes in the manufacturing environment brought about by legislation, currency exchange rates, new evolving markets and so on.

In this part of the section, we will look at manufacturing as a broad engineering activity, and also at some of the details of manufacturing processes, to show the myriad ways in which raw materials can be turned into the products that we see around us.