4.2 Manufacturing processes: making things

We can't hope to cover all manufacturing processes here – that would be beyond the scope of this course. Instead, you'll have a chance to explore a selection of traditional processes and some that have been developed more recently. This should allow you to appreciate the main principles involved and add further to your understanding of how choosing a process to make a particular product is intimately bound up with the product design and the selection of a material to make it from.

Remember the ballpoint pen you looked at, albeit briefly, in Section 1? Manufacturing techniques such as extrusion, injection moulding and machining were mentioned there. Here you'll be introduced to these processes in more detail, as well as to a range of others. Studying this first part of Section 4 should equip you to have a reasonable stab at deducing the methods used to manufacture many of the objects around you.

Activity 33 (exploratory)

Write down some ideas about how the following products could be made. I'm not expecting you to know or even to research specific manufacturing processes. I want you instead to think about the challenges you would face when setting out to make each one:

- sewing needle

- engine crankshaft

- disposable cutlery

- Maltesers/Whoppers.

Answer

I hope you came up with at least some of the following thoughts. You may even have come up with more than the few ideas I have put down here.

- Sewing needle – It's long and thin with a sharp point at one end and a hole at the other. It is made of metal, so it is probably best to start with a piece of wire and shape it. You could grind down one end to a point and punch a hole in the other.

- Engine crankshaft – This is a big, heavy metal object that has to withstand a lot of stress at quite high temperatures for many years. It's also quite a complicated shape and has some very precise dimensional requirements. I need to know the options for shaping large chunks of metal before I can say how something like this is made.

- Disposable cutlery – We see these everywhere. They're made from plastics but they have quite complicated shapes. So my guess would be some kind of stamping or casting process.

- Maltesers/Whoppers – Now there's a challenge. It's a honeycomb centre – like a spherical biscuit – with chocolate on the outside. I think I would bake the core in a little mould and then try to dip it into liquid chocolate. But the difficulty would be getting the chocolate to make a uniform solid coating.

It will be helpful if we base our look at manufacturing processes on a specific example. We need a fairly simple product but one that can be made from a variety of materials that, in turn, require a range of processes.

The product I've chosen is a simple gearwheel. Why use this example? There are several reasons.

- Gearwheels are found in various forms in myriad applications such as all kinds of industrial machines, cars, aeroplanes, ships, domestic products and even toys.

- It is a product that is easily understood.

- It has a mechanical function, requiring physical properties that suit the particular application, for instance gearwheels in a food mixer (Figure 54(a)) must be made of a durable and strong material whereas a flying toy helicopter requires gearwheels that are robust but as light as possible (Figure 54(b)).

- There are many different routes by which it could be made and many different materials that it could be made from.

In a food mixer, there is a single motor that drives one or two shafts to which the attachments are connected. These interchangeable attachments are fitted to one end of a series of toothed gearwheels, known as a gear train, the other end of which is coupled to the electric motor. We're going to look at just one gearwheel in the gear train of a typical mixer.

Not all manufacturing processes can be used sensibly to make gearwheels, so occasionally we'll look at the manufacturing aspects of some other comparably simple components.

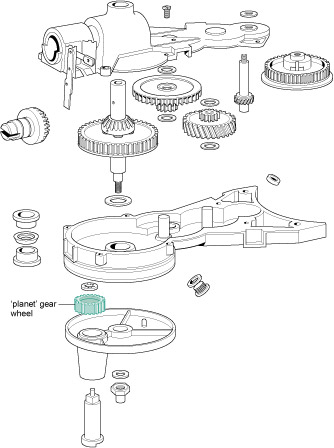

Figure 55 shows an exploded view of the gear train from the food mixer in Figure 54(a). You can see that this is a fairly complex assembly of intermeshing parts. The complexity arises because not only does the mixing tool spin on its own axis but the axis itself also moves around a circular 'orbit' in the bowl of the mixer. In addition, this particular gear train 'gears down' the motion from motor to tool by a factor of 20. But don't worry about the details of Figure 55. We're going to concentrate on the simplest gearwheel in this assembly, the one labelled as the planet gear. A photograph of this and its associated static ring gear (hidden from view in the exploded diagram) is shown in Figure 56.

As you work through this section, I shall return to the gear wheel and get you to think about the different ways it could be made.

The information in this part is organised using three Ps, which are designed to help you choose appropriate manufacturing processes in different scenarios:

- Process – the fundamental approach taken to shaping a quantity of material.

- Properties – the materials properties needed in a product or component and how they can be affected by the shaping strategy.

- Product – the external form or 'shape' of the component.

But before that we need a couple more ideas to help organise the large volume of information on processing in order to help you decide what is feasible or desirable.