article icon

article icon

Science, Maths & Technology

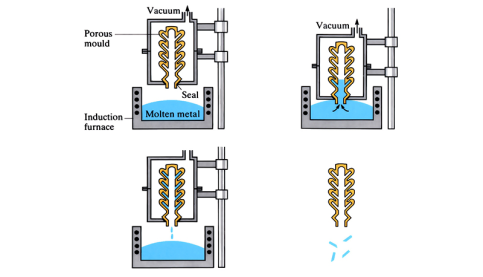

CLA – Hitchiner process

A vacuum is applied to a hollow investment mould sealed within a chamber, causing molten metal to rise upwards into the hollow. The vacuum is released when the metal has solidified. Chandler-Lamb were the originators, and Hitchiner is the company.

article icon

article icon

Science, Maths & Technology

Ceramic mould casting

Ceramic slurry is poured over a relief pattern and left to solidify, forming a cavity mould in the shape of the component to be cast. Cope and drag parts are produced. Each ceramic part is hardened by high temperature firing, then fitted together to make one hollow mould in which to cast the molten metal.

article icon

article icon

Science, Maths & Technology

Resin shell casting

A thin shell of resin-bonded sand is formed around a heated metal pattern. Separating the shell from the pattern and clamping it to a mating shell forms a complete mould into which metal can be cast.

article icon

article icon

Science, Maths & Technology

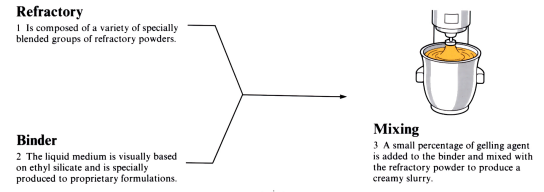

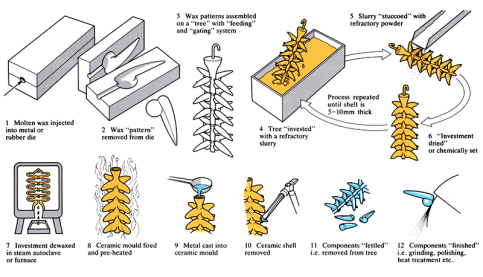

Investment casting

A temporary initial pattern is made from wax. The mould, or investment, is made by dipping the wax pattern into a vat of refractory slurry, which solidifies around the outside of the wax pattern. This process is repeated until the required wall thickness is achieved. The original wax pattern is then melted away, leaving a hollow mould in which ...

article icon

article icon

Science, Maths & Technology

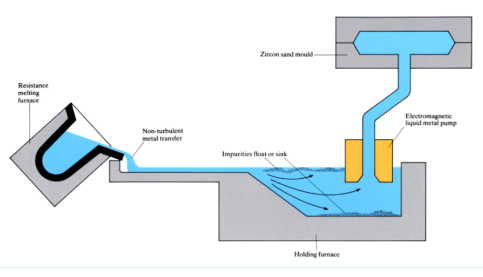

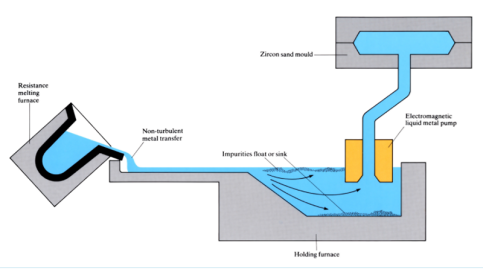

Low pressure sand casting

To reduce porosity in the cast 3D component, molten metal is poured slowly, to avoid turbulence, into a holding furnace. The molten metal is then gravity fed upwards, through a riser tube, and into a sand mould to solidify.

article icon

article icon

Science, Maths & Technology

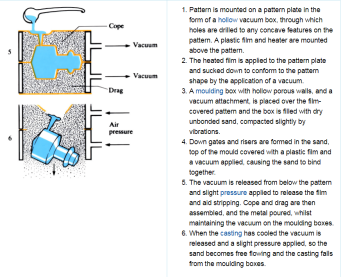

"V" Process (Vacuum sealed moulding process)

Plastic films and sand are sculpted over a pattern using heat, vibration and vacuum to form a mould in the shape of the component to be cast. Suction by vacuum is used to hold the mould in place until the molten metal has solidified.

article icon

article icon

Science, Maths & Technology

Sand casting

Sand is used as the mould material. Sand is compacted round a pattern, into a two part mould, to form a cavity in the shape of the component to be cast.

article icon

article icon

Science, Maths & Technology

Injection moulding

A process where polymer pellets are melted, then hydraulically injected into a mould to solidify into 3D thermoplastic components.