2.2.3 Insulation materials and their properties

The heat flow through walls, roofs and floors can be reduced by incorporating one or more of a range of insulating materials. In these conduction is the main mechanism of heat flow.

In order to understand the insulation thickness required to achieve a given thermal performance for a building, it is necessary to look at heat flow in more numerical detail.

As described above, heat energy will flow through any substance where the temperature on the two sides is different, and the rate of this energy flow depends on:

- the temperature difference, Tin − Tout, between the two sides (often written as ΔT)

- the total area available for the flow

- the insulating qualities of the material – its thickness and its thermal conductivity.

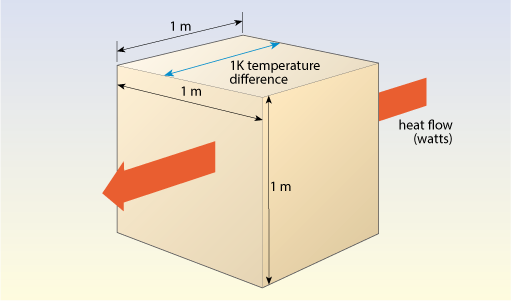

The thermal conductivity is denoted by the symbol ‘λ’ (Greek lambda), although you will also find the symbol ‘k’ used. In this course we have used λ. Its units require a little explanation. It is usually expressed in terms of the rate of heat flow in watts that would flow across a one metre cube of the material with a temperature difference of one degree (kelvin or Celsius) across it (see Figure 6):

λ = heat flow per square metre of area divided by temperature difference per metre of thickness.

The heat flow per square metre has units of W / m2. Temperature difference per metre of thickness has units of K / m. Heat flow per square metre divided by temperature difference per metre has units of:

(W / m2) / (K / m) or

(W / m2) × (m / K) or

W m / m2 K or

W / m K

Thermal conductivity, λ, thus has units of watts per metre kelvin, W / m K or W m-1 K-1.

The lower the conductivity the better the level of insulation.

Table 3 gives thermal conductivities for some common building materials, together with their densities; generally the higher the density, the higher the thermal conductivity.

| Material | Density/ kg m–3 |

Thermal conductivity/ W m–1 K–1 |

|---|---|---|

| Aluminium (window frames) | 2727 | 220 |

| Steel wall ties | 7900 | 17 |

| Reinforced concrete (2% steel) | 2400 | 2.5 |

| Window glass | 2600 | 1.05 |

| Brickwork (outer leaf) | 1700 | 0.77 |

| Plaster (dense) | 1300 | 0.57 |

| Lightweight aggregate concrete | 1400 | 0.57 |

| Aerated concrete | 600 | 0.18 |

| Aerated concrete (lower density) | 460 | 0.11 |

| Timber (softwood) | 500 | 0.13 |

Metals have very high thermal conductivities and can transmit large amounts of heat for small temperature differences. Metal window frames, lintels over windows and fixings used for insulation can transmit considerable amounts of heat even though they only have a small total area. These are often referred to as ‘thermal bridges’ or ‘cold bridges’. Window glass has a high conductivity, so using thicker glass will have almost no effect on their overall U-value. Structural building materials such as brick and concrete have lower conductivities but the potential heat losses are still considerable due to the large surface areas of walls and roofs.

Insulation materials make use of the fact that still air, or other gases with a reasonably large molecular weight, are good thermal insulators. Most practical forms of insulation rely on using very small pockets of these gases. There are four kinds of commercial insulation material:

- various grades of aerated concrete containing small bubbles of air

- foamed glass containing small bubbles of air

- various forms of wool made up of fibres with air held trapped between them

- plastic foams containing small bubbles of gas.

Vacuum insulated panels (VIPs) using plastic foams with ‘bubbles’ of a vacuum have considerably better performance. They are becoming increasingly available, but are very expensive. Their application for refrigerators is described later in Section 4.1.2.

Aerated concrete, whose thermal properties are listed in Table 3, is not as physically strong as its dense counterpart. There is a trade-off of compressive strength against thermal insulation performance. In practical construction this material can be used to form the inner leaf of a cavity wall supplementing the main insulation, which is likely to be some form of mineral wool or plastic foam within the cavity. Figure 7 shows samples of these commonly used insulation materials.

Wool and plastic foam insulation materials are very light; their densities are typically only 15–30 kg m–3. Table 4 below gives some sample conductivity values for them, taken from manufacturers’ literature.

| Insulation material | Thermal conductivity/ W m–1 K–1 |

|---|---|

| Foamed glass | 0.045–0.055 |

| Mineral or glass fibre wool, sheep's wool, cellulose or hemp fibre | 0.032–0.040 |

| Expanded and extruded polystyrene foam | 0.030–0.040 |

| Polyurethane foam | 0.025 |

| Polyisocyanurate (PIR) foam | 0.023 |

| Phenolic foam | 0.022 |

Footnotes

Note: Specialist vacuum insulation is described later in Section 4.1.2.The most commonly available forms of insulation material are mineral wool (often called ‘rockwool’ or ‘earth wool’) and glass fibre wool.

Modern manufactured rock wool is the result of discoveries made in Hawaii of the effects of superheated steam on molten rock during volcanic eruptions. In the manufacturing process a suitable rock is melted at over 1500°C. It is then spun out through small holes on the perimeter of a centrifuge to produce long, thin fibres. Glass fibre manufacture is similar. The fibres may then be coated in a plastic resin and sold either as thick rolls or formed into flat square batts of insulation.

Plastic foam insulation materials are made by blowing a gas into molten plastic. Expanded polystyrene is a very familiar example widely used for packaging; other plastics used include urea formaldehyde, polyurethane, polyisocyanurate and phenolic resin. Their foams have different properties. Polystyrene foam, for example, can be made extremely strong and rigid. It is water-resistant and sufficiently strong to carry the weight of vehicles and so it can be used under factory floors. It can also be produced in blocks that can be quickly clipped together to build insulating shuttering into which concrete can be poured (see Figure 8).

Insulation materials can also be made from natural materials such as sheep's wool, cellulose fibre, wood fibre and hemp fibre.

Any practical insulation choice must take into account:

- thermal insulation performance

- cost

- ease and safety of handling

- compression resistance

- life expectancy

- water resistance

- fire resistance

- any possibility of producing dangerous fumes

Typically, plastic foam insulation materials have only two-thirds of the conductivity of wool or fibre materials, so the same insulating performance can be achieved with a smaller thickness.

There is considerable debate on the relative environmental friendliness of different materials.

The naturally occurring rock fibre, asbestos, is now banned because of associated health problems (the fibres are fine and brittle and break down into a fine dust that can be breathed in). Modern mineral and glass fibre wool are safer, though it is advisable to wear a face mask when using them in confined spaces.

Plastic foams use oil-based chemicals and, being plastic, are inflammable and can produce toxic smoke when burning. Urea formaldehyde foams, widely used in the 1980s, have now been largely replaced because of the slow leakage of low levels of toxic formaldehyde into the interior spaces of buildings.

Also, until the 1990s, the gases used to 'blow' many of these foams, creating bubbles, were chlorofluorocarbons (CFCs). However, these were found to be damaging the ozone layer in the upper atmosphere. They are also strong greenhouse gases, contributing to global warming. As a result of these environmental concerns, they have been replaced with other gases. Pentane has been widely used, but this increases the flammability of the insulation and suitable precautions must be taken with its use. More recently, hydrofluoroolefins (HFOs) have been introduced by some insulation manufacturers. These have a lower flammability and global warming potential.

In comparison, mineral wool and glass wool are relatively inert materials. However, their manufacture requires energy to produce the high temperatures to melt the materials. Even so, the manufacture of glass fibre or rockwool insulation only uses about a third of the primary energy of plastic foam insulation.

The energy used to manufacture insulation materials can be reduced through recycling. Recycled materials can be used in glass fibre insulation and some plastic foams. Recycled newspaper is the main ingredient of cellulose fibre insulation.

The overall energy used in manufacture sets limits to the maximum economic thickness that is worth using. For example, a domestic roof space in the UK might have 80 mm of existing insulation. Adding a further layer of 200 mm of glass wool will save heating energy, but it is likely to take between two and three years to recoup the energy used to make the insulation.