3.3 Dams

To economize on constructional materials and costs, it is desirable to build a dam at a narrow part of a valley so that the dam can be kept as short as possible. The quantity of constructional materials needed to build dams, and their cost, can be enormous. The Aswan High Dam, built during the 1960s, cost £400 million for a 1.2 km dam. Though shorter than the Aswan High Dam, the longest dam in Britain, the Kielder Dam in Northumberland (Figure 17), which was completed in 1980, was part of a scheme costing £150 million.

There are two fundamental types of dam, which have different ways of withstanding the pressure of water in the reservoir behind them: gravity dams and wall dams. The gravity dam depends on its own weight to prevent deformation or movement, whereas the wall dam is a rigid structure that resists deformation and transfers the pressure of the water to the floor and sides of the valley. Some dams are a combination of both types.

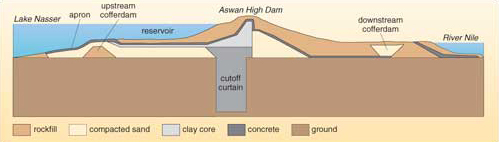

The simplest form of gravity dam is made up of carefully selected unconsolidated material such as clay or broken rock. This is called an earth dam (although it is not made of garden-type earth!). Earth dams usually have an impermeable clay core to reduce the seepage of water through the dam, and the sides are usually covered with broken blocks of rock or concrete to reduce erosion by waves. Gravity dams can also be constructed entirely of piled-up masonry (stone blocks) or concrete. Masonry or concrete gravity dams are usually built if the reservoir site is a narrow valley, but if a reservoir has to be built in a wide valley or in a lowland area, earth dams are used as they are less expensive. Figure 18 shows how the Aswan High Dam, an earth dam, was built. The Kielder Dam is also an earth dam (Figure 17).

Wall dams are usually built only in narrow valleys, when a relatively high dam is needed. They must be strong and impermeable, and are made of masonry or concrete. Their strength is often increased by making them curved in plan (convex towards the reservoir, just as curved arches are used to support heavy roofs in churches), or with buttresses on the downriver side (similar to those used to stop church walls falling outwards), or by reinforcing them internally with steel cables. The Hoover Dam on the Colorado River is an example of a wall dam (Figure 13).

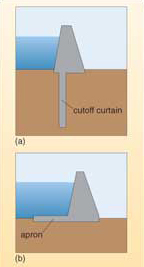

Seepage below dams can be reduced by a cutoff curtain and/or an apron. A cutoff curtain is a narrow impermeable layer, usually made of concrete, extending vertically below the dam, to reduce horizontal seepage of water under the dam (Figures 18 and 19a). The cutoff curtain extends downwards to a depth that is usually greater than the height of the dam, and if possible goes down into impermeable rock. An apron is a horizontal impermeable layer at the foot of the dam wall to reduce downward seepage from the reservoir (Figure 19b).

One of the problems of building a dam in the valley of a major river lies in excluding water from the dam site while the dam is being built. Small temporary dams, called cofferdams, are often constructed for this purpose, and are sometimes incorporated into the main dam (Figure 18).