The circular economy in China

Across the nation as a whole, China’s resource use is much less efficient than that of many other countries. It is estimated that it uses around five times more material inputs to generate the same amount of outputs when measured in terms of Gross Domestic Product (GDP) and compared against the average across many developed countries (Mathews and Tan, 2016). You have seen that China also produces colossal amounts of MSW that have risen at rapid rates, and is not as effective as many other countries in using principles of the waste hierarchy to manage the waste and turn it into a resource through reuse and recycling.

But China is starting to tackle these resource inefficiencies and is taking action to make some serious changes that it hopes will bring about long-term improvements. For several years, China has embraced the notion of the circular economy, particularly the elements of the circular economy that focus on industrial wastes and on turning the outputs from one manufacturer into the inputs of another.

In 2004, the circular economy concept was written into China’s 11th Five-Year Plan (for 2006–10) which made it an important target for social and economic development. In 2009, the Circular Economy Promotion Law of the People’s Republic of China was enacted. This helped to promote circular economy programmes and initiatives, including introducing eco-industrial parks to encourage mutually helpful and sharing relationships between manufacturers, involving utility supplies such as energy and water, electronics, food and beverages as well as reuse and recycling (Winans et al., 2017).

The circular economy concept was upgraded to a national development strategy in the 12th Five-Year Plan (for 2011–15) which included targets for reusing industrial solid wastes and increasing resource use productivity – ‘getting more out for what’s put in’. China has produced the first ever national strategy for achieving a circular economy, and the 13th Five-Year Plan (for 2016–20) extends the reuse, recycling and productivity targets, as well as renewable energy source targets.

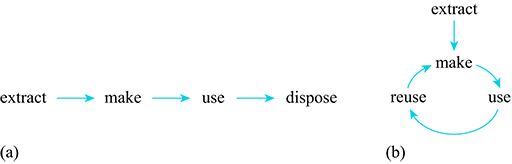

Initiatives to implement the circular economy concept in China appear to be driven mainly by changing or redirecting flows of materials, to move away from the linear economy of ‘extract, make, use, dispose’ to a closed system of ‘extract, make, use, renew resource’, embedding the 3Rs principles of reduce, reuse and recycle. These contrasting strategies are shown in Figure 15. China sees these changes being enacted across different levels in society – individual enterprises (micro-level), clusters of geographically located firms (meso-level), and across industries, regions or at the national level (macro-level). The country has circular economy ambitions that reflect these different levels, based on a ‘10-100-1000’ plan to implement 10 major industrial waste recycling programmes, 100 circular economy demonstration cities, and 1000 demonstration enterprises or industrial parks nationwide (Mathews and Tan, 2016).

One of the first eco-industrial parks to be approved by the Chinese Ministry of Environmental Protection as part of a national demonstrator programme was the development of Suzhou New District (SND). SND is a large industrial zone near Shanghai in southeast China, and is home to over 16 000 commercial enterprises and around 4000 manufacturing firms mainly in IT and electronics, but also includes biotechnology, chemical engineering, medical and pharmaceutical, iron and steel, and textile companies. Figure 16 gives a bird’s-eye view looking over SND.

SND has several success stories of outputs from one manufacturing process being treated within the district and then used as inputs for another, including waste metals and reclaimed copper, clay and waste ammonia. SND claims a number of efficiencies from its circular economy initiatives, including reduced energy consumption, increased solid waste recycling and reduced emissions of pollutants. What is driving this is not just an environmental resource and impact issue, it is an economic one too. Locally regenerated and recycled materials are usually cheaper than externally sourced raw materials, which helps to increase profits.

Achieving the closed loop waste output to the resource input aim of eco-industrial parks is technically more straightforward for some industries than others, for example where waste outputs are uncontaminated and easily separated, such as waste metals. Reclaiming useful materials from mixed and contaminated waste such as industrial sludge is far more technically challenging. There can be behavioural challenges too: encouraging firms to work together may require incentives, but even then there can be geographical and logistical obstacles. Despite this, China is making progress. In 2012, there were 15 officially recognised eco-industrial parks with a potential 49 under construction (Bai et al., 2014). China is also well placed to develop further opportunities as more than half of its manufacturing base is geographically clustered in industrial parks. Being a relative newcomer to industrialisation may also have its advantages:

While it must be understood that China faces enormous obstacles in implementing the circular economy idea, and starts from a very low base in doing so, nevertheless it has certain latecomer and administrative advantages in putting its economy on a new, closed-loop footing, as compared with more advanced countries with established industrial systems.