6.3 Biochemical processing

Biochemical processes rely on the use of microorganisms to convert biomass into more useful forms of bioenergy. Processes include anaerobic digestion, fermentation and enzymatic conversion.

Anaerobic digestion

Anaerobic digestion (AD), is digestion in the absence of air. In this process, bacteria break down organic material into sugars and then into various organic acids, which are further decomposed to produce biogas. The feedstock may include dung or sewage, food processing wastes or discarded food, agricultural residues or specially grown silage crops that are harvested green. Digestion can take place in either wet or dry systems.

The biogas produced can be burned to produce heat or used to fuel an internal combustion engine to drive a generator for electric power.

At present, the majority of the UK’s anaerobic digestion capacity is in the landfill sector, as much of municipal solid waste is of biological origin, and its disposal in landfill sites provides conditions for anaerobic digestion to occur naturally. The gas is mainly used for electricity generation.

Municipal Solid Waste can also be subject to more controlled anaerobic digestion, enabling much higher and quicker gas yields.

Fermentation to produce ethanol

Here the simple sugars from the biomass feedstock are converted to ethanol and carbon dioxide by the action of a different set of microorganisms, usually yeasts. The ethanol is then separated from other components using heat to distil the mixture, so that the ethanol boils off and can then be cooled and condensed back to liquid.

Enzymatic conversion

Fermentation to produce ethanol requires some form of soluble sugar, but much biomass consists mainly of cellulose, hemicellulose and lignin. Following a pre-treatment of such material by, for example, hydrothermal processing, the watery suspension of cellulose and hemicellulose that results can be treated with enzymes. These biological catalysts are usually derived from microorganisms such as bacteria or fungi, and can break down the cellulose and hemicellulose to simpler carbohydrates that can be used in traditional fermenters.

Such combinations of thermochemical and enzymatic conversion processes that allow cellulosic biomass to be used for the production of ethanol are now termed advanced or second/next generation bioethanol technologies. They can increase supply of feedstocks while avoiding competition with food or fodder supply and more easily meet bioenergy sustainability standards.

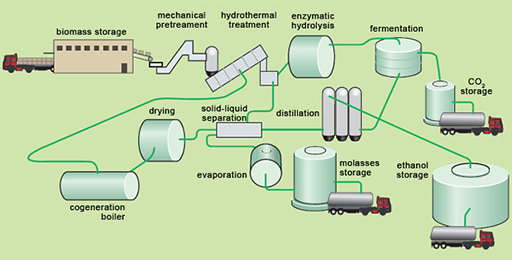

An schematic view of a pilot-scale second generation plant set up by Inbicon in Kalundborg, Denmark (Inbicon, 2010) is shown in Figure 11.

You will now move on to discuss the environmental impacts of bioenergy.