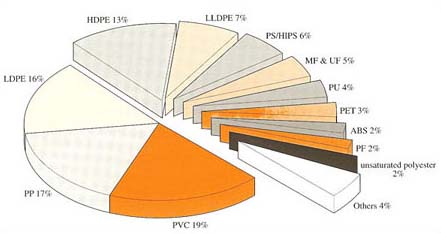

1.2.3 Consumption of plastics

The consumption of plastics in the UK today is shown in Figure 6, with usage being dominated by PVC, closely followed by a range of polyolefins (polypropylene, various polyethylenes) and materials based on styrene monomer (PS and HIPS). These are the ‘big five’ bulk commodity polymers which dominate the market, and which have found application in almost every sphere of human activity (Figure 2). PVC is produced either in a flexible, elastomeric form (plasticized PVC) or as the rigid material familiar in pipes and profiles (unplasticized or uPVC). The ubiquitous plastic bag is usually made from any of the grades of polyethylene, and polypropylene is widely used for wrapping of consumer products. Polystyrene by itself is quite brittle, so is often used in its reinforced form (HIPS), or alternatively as a lightweight foam for insulation or protecting sensitive goods in transit.

These five are followed by thermosetting melamine and urea formaldehyde, widely used for electrical insulation products as well as for reinforcing wood products. Polyurethanes are a very versatile group of polymers – they may be thermoplastic or thermosetting, and range in stiffness from flexible elastomers to stiff plastics. Stiff grades are used for car body panels, and in foam form for insulation, flexible foam being used in furniture. Another grade is widely used in paint varnishes. Polyester, PET, originally mainly used as a strong fibre, is often nowadays used in blends with cotton in textile fabrics. But its greatest application today is in tough lightweight bottles, displacing glass for its safer properties. ABS is a derivative of PS, being much tougher by blending with rubber particles, and so is widely used for enclosures. The oldest synthetic thermoset, PF, is used for reinforcing wood products, while unsaturated polyester forms the main matrix material for glass-fibre reinforced composites. Acrylics, which comprise PMMA and related polymers, first found use in transparent aircraft windows during the Second World War, especially since they could be easily formed into complex shapes. They should not be confused with acrylic fibre, actually based on a quite different chain structure, that of polyacrylonitrile or PAN.

Although consumption of the remaining named polymers in Figure 6 is relatively low, they represent a growing class of so-called engineering polymers, whose properties are often so unusual or interesting as to find unique application in addition to displacing traditional materials. The family of nylons centres around nylon 6,6 and 6, both invented in the 1930s, the former still popular as a fibre, although both forms are used for mouldings. A more spectacular example is aramid fibre, developed in the late 1970s in the USA, for its very high stiffness and resistance to high temperatures. These properties have resulted in aramid fibre being widely used in textiles, ropes and composite structures such as aircraft tailplanes and rotor blades (often in combination with epoxy resins). Acetal is a tough, crystalline polymer which until recently was widely used for domestic kettles. Polycarbonate also finds use as a tough material for consumer products, and displaces PMMA owing to its greater toughness. PBT is another kind of thermoplastic polyester mainly used as a moulding material. The fluoropolymers are a unique class of polymer exemplified by PTFE, the parent material used most frequently for its exceptionally low coefficient of friction and temperature resistance as in non-stick frying pans, plumbing tape and support pads for moving heavy equipment. A related elastomer, Viton rubber, is used for engine seals and aircraft hose.

Exercise 2

For the various polymer plumbing applications in modern houses, identified in Exercise 1, attempt to identify the specific polymers used in each product or range of products.

Answer

-

water supply pipe: uPVC or HDPE or polybutene; tank fittings: PE, PP, nylon or POM.

-

bath: PMMA/GRP or ABS

-

fittings: often ABS

-

film covering: LDPE

-

moulded tank insulation: UF foam

Sewage pipe: uPVC; fittings: PP or HDPE

-

Rainwater goods: uPVC

-

DPC: LDPE

Flat roofs: bitumen/fabric or EPDM vulcanized rubber.