1.3 Product design and manufacture

So what are the reasons for the continued growth in the use of polymers as shown in Figure 1? It cannot be raw material cost, since the source of synthetic polymers is crude oil or natural gas, prices of which have risen over the same period of time. The comparative prices of polymers are considerably greater than traditional materials like mild steel, so we must look elsewhere for their success.

It is really necessary to focus on their end uses, as finished products, to even begin to attempt an answer. The largest area of consumption is that of packaging (Figure 2), where plastics are used to enclose perishable products such as food, drink, and fragile goods such as glassware and ceramics. Food preservation is a vital service today, where perishing by drying out or bacterial contamination has been reduced in Britain from between 30 to 50 per cent to 2–3 per cent in the last 50 years. Such packaging as shrink-wrap film, plastic bags and other containers, and foamed PS are now commonplace both for cooked and raw foodstuffs. Plastics are not alone here, because the ‘tin’ (actually steel or aluminium) can and glass bottle have also helped reduce wastage and harmful contamination (Figure 7). However, polymers do have a competitive edge in their low density and hence lower weight during transport. Thus vegetables are much more widely distributed in plastic packs, where deterioration is halted not by totally enclosing them in a metal can (so excluding air) but by freezing the vegetables and maintaining them at a low temperature in a film of low-air permeability. Carbonated soft drinks bottles are now almost universally made from PET, a tough transparent polymer, which cannot injure the consumer if it breaks and is substantially lighter than its glass equivalent. The barrier behaviour of polymers is not always as good as inorganic materials, but careful selection of impermeable polymers can reduce air penetration to a minimum. Thus PVDC is widely used to coat PET beer and cider bottles to prevent diffusion of air into these products and hence prolong their useful shelf-lives. Even with metal cans, plastic coatings are normal because they can be printed easily, and can contribute to product strength and barrier resistance.

Exercise 3

In building products, polyethylene DPC (damp proof course) and uPVC rainwater goods have largely displaced traditional materials like slate and steel or cast iron. Indicate what design factors have created this situation.

Answer

Slate DPCs have been displaced by LDPE membranes for several reasons. LDPE film can be made in very large sizes (metres in width and length) whereas slate is limited to small sizes (cm in width and length). Slate is also expensive, occurs only in limited locations and is of much higher density, so incurs high transportation costs when compared with LDPE. It is a brittle material, so cracks may develop and encourage water permeation, so affecting the integrity of the product when in place. LDPE, by contrast, is tough and ductile, so can withstand high stresses imposed during installation or use.

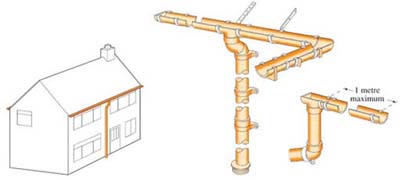

Rainwater products such as guttering and downpipe in uPVC are the preferred alternative to cast iron, mainly because they are substantially lighter (so installation is easier), easier to make in large lengths, safer to install since PVC is tougher than brittle cast iron and cheaper as a manufactured product. It is also much more corrosion resistant than steel guttering or pipe, so should last very much longer.

So polymers do have certain intrinsic property advantages which have helped in designing new products. The most obvious one is low density for ease of transport and installation, but corrosion resistance is also important for products destined for a long life in a building (Figure 8). Ease of manufacture helps lower production costs, and also enables large sizes to be made. Most of these properties are also important in other areas of product design, especially in automotive, consumer, household products and office equipment (Figure 2).