1.3.3 Speciality sectors

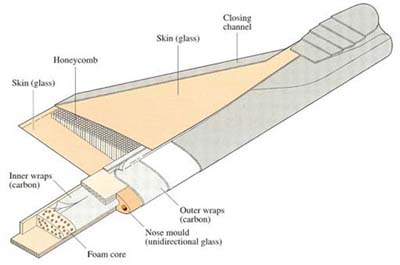

There are many sectors of the market where polymers have made dramatic inroads, including medical/ethical, leisure and aerospace products. The influence of density as a property is most dramatic in the last area, simply because weight saving on aircraft fuselages creates large savings in fuel usage or, alternatively, means that more passengers and/or freight can be carried per aircraft. Although complete polymeric fuselages are rare, only being used to date in small aircraft (such as the ‘Learjet’ and ‘Gossamer’ man-powered plane) or military craft (such as the ‘Stealth’ fighter and bomber), composite wings, tailplanes and rotor blades are increasingly displacing conventional aluminium equivalents (Figure 12). And the reasons for this move are not just for the great weight savings offered. A crucial reason is the increase in mechanical integrity, since the fatigue resistance of composite structures is much greater than metal alloy because cracks are difficult to initiate and propagate owing to the multiplicity of interfaces within the material. Catastrophic propagation following slow and often undetectable hairline cracking from fatigue is a well-known failure mode for all metal aircraft. The increase in product integrity is well worth the extra manufacturing cost of composite materials.

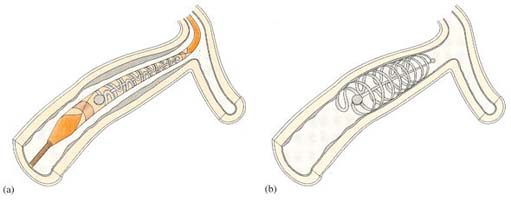

Products now widely used and accepted include catheters, serum bags and stents (Figure 1). In all these areas, polymers offer resistance to body fluids, and mechanical compatibility with body tissues, such properties being related to those already discussed above, namely, corrosion resistance and low and controllable stiffness.

Other materials are used in combination with polymers, where specially high stiffness may be required (e.g. needles) or where shaping is easier (e.g. the ball part of the joint in replacement hip joint. Similarly, stents for supporting weakened or collapsed veins and arteries are more often made using special metals such as tantalum and platinum rather than polymers. The balloon catheters which inflate them in place, however, are universally elastomeric since the long-range elasticity needed is a property unique to this group of polymers.

Medicine and surgery have also seen a dramatic increase in the uses of polymers, enabling people to live longer lives with implants which replace diseased body parts. Such devices range from hip joints and heart valves to synthetic skin and bone. Invasive surgery has exploited many of the new polymers for a wide range of equipment, where disposability is actually an added bonus for the reduction in the chance of infection.

With improved productivity across wide swathes of industry, there are now much greater opportunities for leisure activities. In this area, there has been much inventiveness in product design, with new sports based on or using polymer products. Surfboarding and windsurfing are activities which demand lightweight products, often composed of thermoplastic or composite skins, sometimes reinforced with foam interiors. Highspeed yachting has shown similar developments in the use of high-performance polymers (Figure 14). In athletics, the Olympic record for polevaulting has increased, partly due to the displacement of wood or metal by composite poles. Tennis too, has benefited, especially with composite rackets which have increased product lifetime by reducing fatigue, and increased performance through the use of light-weight materials.

Self assessment question 2

Thermoplastics have come to predominate as the preferred material for toys. A common design of children's building blocks involves the blocks locking together on one of their longer sides by means of raised bosses which fit into recesses in the bases of the blocks. Discuss the design factors which have made plastics the preferred choice of material. Include in your discussion mention of

-

polymer chemical properties,

-

physical properties,

-

product safety, and

-

ease of manufacture.

Answer

Building blocks of the kind shown can be moulded in one piece in a single operation, so displacing wood as the preferred material. Wood requires several machining operations to create complex shapes, so would be more expensive to use for this shape. In terms of chemical properties, plastic is resistant to rot and natural degradation, but care might be needed in additives used because the product might be chewed by the user!. The properties are similar in all directions, while wood varies depending on the direction. The stiffness of plastics is lower than wood, so care would be needed in design to ensure that the wall thickness is great enough to withstand handling stresses as well as the pushfit stresses. A tough thermoplastic should be used to resist impact loads.