3.2.2 Ethane cracking

Although ethane can be cracked thermally, the reaction is slow and does not necessarily yield ethylene at high severity. Careful control of reaction conditions, however, allows the reaction to occur

The yield of ethylene is typically nearly 50 wt% with the rest composed of unreacted ethane (40 per cent) and some methane and hydrogen (10 per cent). The ethane is separated and recycled to the start. This process is practised widely in the US, where ‘wet’ natural gas has traditionally been abundant and cheap. With supplies arriving in Scotland from the Brent complex, ethane and propane are cracked at the Shell-Esso petrochemical works at Mossmoran, Fife and the BP Grangemouth complex near Edinburgh.

Box 7 North Sea oil

Although we all know that Britain is effectively self-sufficient in oil and gas, and indeed exports substantial quantities, it may not be so widely appreciated that our oil is of very high quality. It attracts a high price on the Rotterdam market because it is low in the impurity sulphur and is also very light. Thus the marker crude oil. Brent, from the UK sector of the North Sea has a sulphur content of only 0.26 per cent compared with 2.5 per cent for Kuwaiti crude. Why should this be important? One of the reasons is that in much petrochemical processing (to make polymers, for example) catalysts are use to speed up process reactions; sulphur poisons such catalysts, so must be removed in expensive purification processes before catalysis. It will also burn in fuels made from crude oil (fuel oil, petrol, paraffin etc.) to pollute the environment, so low sulphur oils generally command a premium on the market.

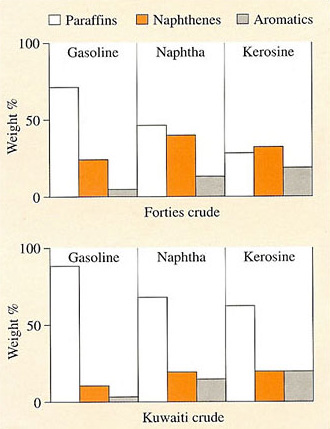

North Sea crudes are also very light, with a density much lower than Middle East crudes. Thus Brent oil has a gravity of about 38 API degrees compared to 27 API degrees for Alaskan crude, for example. This means that it yields more light fraction liquids such as petrol (gasoline), which are more valuable than heavier fractions. Thus Brent yields about 20 weight % petrol compared with only 10 per cent for Alaskan crude. There is a more subtle reason why our oil is of greater value, the reason lying in its molecular composition. Although an incredibly complex mixture of organic compounds, oil composition can be expressed in terms of paraffins (alkanes), naphthenes (cyclic paraffins) and aromatics. The compositions of a typical North Sea crude and Kuwaiti crudes are shown in Figure 34, where it is clear that North Sea oil is much more naphthenic and aromatic than Kuwaiti. This is important for petrochemical extraction of high value aromatics for polymers like PS and PET, as well as increasing the octane rating of car petrols, especially for lead-free varieties.

In the US, however, ethane and propane are becoming more expensive, so that thermal cracking of naphtha to produce ethylene is increasing. There is no doubt that thermal processing of ethane and propane to produce monomer is more efficient because separation costs both before and after processing are much lower; it also means that dependence on a semi-fixed product distribution is much less (Figure 33).

In recent years, there have also been attempts to recover previously flared wet gases from the rich oilfields of the Middle East; conversion to petrochemical building blocks like ethylene clearly offers greater added-value products like polyethylene. There is now a large and growing petrochemical industry in the Middle East, and interestingly, Norway, where the enormous reserves of high-grade oil and wet gases from the North Sea assure supplies for many years to come.