4.3.5 Co-ordination polymerization

While most free radical and ionic polymerizations are carried out homogeneously, there is another important class of reaction which is often performed with solid catalysts. These reactions, discovered in the mid-fifties, have revolutionized polymer manufacture by permitting much less severe polymerization conditions than with other systems and by allowing a greater degree of control of polymer structure. Ziegler-Natta catalysts, as they are called, will convert vinyl and diene monomers to highly linear, stereoregular structures under ambient conditions.

The prototype of all vinyl polymers, polyethylene, was first discovered quite accidentally in the 1930s as the result of a very high pressure experiment; low density polyethylene is still made under such conditions. However, the thermodynamics of the polymerization reaction indicated that the reaction should be possible at a pressure of 1 atmosphere and a temperature of 300 K, if the right catalyst could be discovered. Suitable catalysts were found to be complexes of aluminium alkyls and titanium halides. It has been suggested that the mechanism of polymerization involves monomer approaching the surface of the catalyst and probably forming a bridge between the metal atoms, while becoming activated at the same time. This is why the mechanism is termed coordination polymerization. More monomer can approach the surface site, react with the active end and grow into chain. The chain thus grows from the surface of the catalyst. Since the activated end is probably partly charged, transfer reactions are much less likely than in free radical situations, so that branching is unlikely. As the monomer molecule must sit in a rather specific position to react, stereoregular polymers can be made.

Molecular masses in Ziegler-Natta polymerizations are often very high, sometimes too high for the polymer to be useful commercially, because too high a molecular mass makes the polymer too viscous to process easily. Molecular mass distributions are often quite broad, probably because active sites on the catalyst surface are sensitive to catalyst poisons.

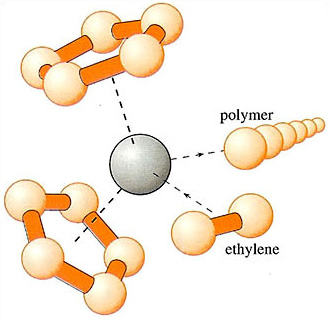

Metallocene polymers are of much more recent origin (1990s). Metallocenes are sandwich compounds of cyclics and metal ions. Monomer is polymerized by the metal ion in a controlled way:

Molecular mass distributions are narrow compared to Ziegler-Natta polymers, with a typical dispersion of 2.5. Such polymers are finding application in packaging and mouldings.