5.2.2 Viscous behaviour

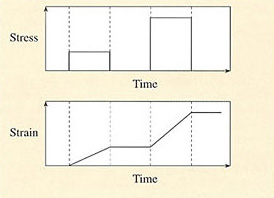

Viscous flow is not recoverable. When the stress is removed from a viscous fluid the strain remains. Hence the work energy is not returned to the forcing agency and has to be otherwise dissipated. Figure 45 illustrates this schematically by showing the strain response in such a viscous material when a simple stress history has been imposed upon it.

For a linear viscous material, the rate of change of shear

strain with time, ![]() is directly proportional to the imposed tensile stress σ

is directly proportional to the imposed tensile stress σ

where η is the Newtonian viscosity of the fluid. In polymer melts, η is not a constant, but depends on the shear strain rate ![]() , with, in general, η decreasing as

, with, in general, η decreasing as ![]() increases. The viscosity is also directly dependent on molecular mass and so inversely related to melt flow index. These factors are thus of direct importance to a processor or moulder.

increases. The viscosity is also directly dependent on molecular mass and so inversely related to melt flow index. These factors are thus of direct importance to a processor or moulder.

Viscous properties dominate during the earlier stages of processing but elastic effects are also important. Molten thermoplastics are obviously highly viscous as are partially polymerized and uncured thermosets and masticated and unvulcanized rubbers. However, observable features such as the swelling of extrudates as they leave dies are manifestations of melt elasticity.

In essence, elasticity in molten polymers arises from the entropy factor or the tendency of the macromolecules to coil into their configurations of maximum disorder. This is in opposition to the stretching which occurs as the material flows under the influence of the stress field.