1.3 Example 1 The Workcenter that didn't

Autodesk Inc. is the world's largest supplier of design and engineering software. It currently markets over thirty products but is most famous for its AutoCAD® two- and three-dimensional design and drafting software. The company is the market leader in this type of application, with over 4 million customers worldwide.

The Autodesk story began in 1982 with a group of programmers, centred on San Francisco, writing code for design software in their spare time. The group demonstrated a cobbled-together revision of what was to become AutoCAD® at an exhibition in March of the same year. The product was finally launched formally in December and was an instant success. By 1987, 100,000 copies of the application had been sold and, by 1999, 2 million. The reasons for AutoCAD's success are:

-

It addressed a known, well-understood and fairly standard need – two-dimensional and later three-dimensional drafting. In this respect it was similar to word processing.

-

The application is widely needed. Design and drafting are undertaken in businesses large and small throughout the world.

-

It made use of the growing power and capability of personal computers. Previously, CAD packages had required a mainframe computer and the few workstations connected to them were situated in special ‘suites’.

-

It was (relatively) easy to use. The extensive training required to use mainframe-based CAD packages was not needed.

-

It was (therefore) affordable and was sold as a standard off-the-shelf package in software retailers.

The company employs over three thousand people worldwide and generated revenues of $820 million in the financial year 1999/2000 (Autodesk, 2000). This example concerns four new or enhanced products that were developed during the period 1992–96.

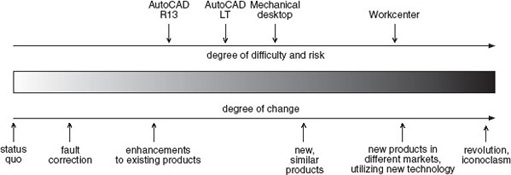

For a while Autodesk, though anxious to develop new products, had a development approach that was described as ‘chaotic’. There was no formal development model or procedure, and documentation was produced as an afterthought. Recognising the problems that arose as a result of this informal way of developing new products, the company developed a product definition process (PDP). This had the stages shown in Figure 1.

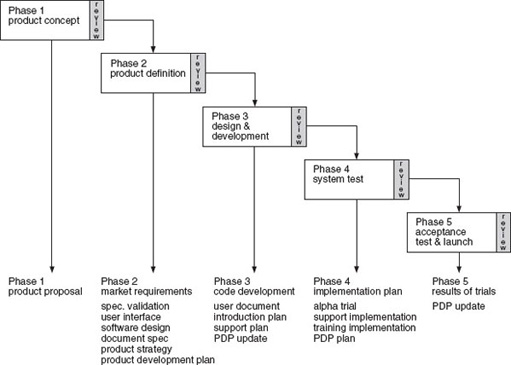

Autodesk's PDP can be characterised as a simplified version of the standard ‘waterfall’ life cycle model of software development shown in Figure 2.

SAQ 1

What do you consider to be the major differences between Autodesk's PDP and the waterfall model depicted in Figure 2?

Answer

Although Autodesk's approach has fewer stages than Eisner's version of the waterfall model, the major difference seems to be the absence of any feedback mechanism between the stages of the Autodesk model. Another difference is the review process at the end of each of Autodesk's stages. However, in reality, the role of the review processes was simply to ascertain the completion of each set of documents and did not consider whether their content confirmed that the work undertaken during the stage had been undertaken competently (Abram, 2001). In this respect a parallel can be drawn with many implementations of the quality standard ISO 9000, which seemed more concerned with ensuring that processes had been accurately documented rather than whether they had been competently carried out.

Autodesk used the PDP to guide the development of four new products during the period 1992–96:

-

AutoCAD Release 13: an update of the original Autodesk package that provides designers and engineers with a personal-computer-based 2D and 3D design and drafting environment and toolset.

-

AutoCAD LT: a version of AutoCAD with reduced features, supporting 2D drafting and design only.

-

Mechanical Desktop: an add-on package for users of AutoCAD that provides additional features for mechanical designers and engineers.

-

Workcenter: a document/data management package implemented on a client-server configuration.

Of these products, three were successful and remain in the Autodesk product portfolio but the fourth, Workcenter, failed to sell in sufficient numbers and was dropped. There were three main reasons for the failure of Workcenter.

First, AutoCAD Release 13, AutoCAD LT and Mechanical Desktop were all closely related to Autodesk's existing product. None of them was a significant innovation. Certainly each had new features, but their basis, application area, market and user bases were already well known to Autodesk. This was not the case with Workcenter. AutoCAD and its derivatives are used by designers and engineers essentially on a standalone basis. Workcenter was intended to integrate the work and management of the different people and departments involved in a project. Its user base was less clear.

Second, as market leader in design and engineering software, Autodesk's file format and interfaces had become a de facto standard. However, document management software has to be capable of accepting many different types of file, produced by a variety of applications. This complicated the technical design of the package enormously.

Third, as suggested earlier, drafting and design processes, at a detailed level at least, are well denned. Engineering drawings are pretty much standard and the way in which they are produced is also standard. They are the graphic equivalent of word processing. This is not the case with document management, where each organisation has its own highly individual way of doing things. The implication of this difference is that whereas a design and drafting package can be used more or less as it stands from the box, the way in which Workcenter was implemented needed to be thought through in a great deal of detail and had to take into account the way that the whole organisation worked. Each implementation had a high degree of individuality. Autodesk's distribution and sales channels were not used to providing the degree of support needed to implement Workcenter, nor was it clear how the extra work was to be paid for.

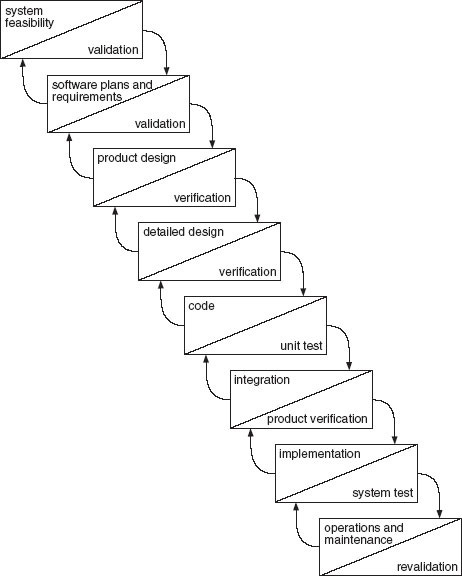

Sticking with the existing situation, the status quo, carries least difficulty and risk (see Figure 3), though it is often, correctly, argued in relation to business development that to ‘do nothing’ is not an option. There are, after all, plenty of examples of enterprises that did nothing only to be driven out of business by their more active competitors. However, at the level of the individual activity, carrying on as normal is least risky.

At the second level of difficulty and risk is fault correction. Any interference in the operation of a system carries some risk, and the phenomenon of engineer-induced faults is well known. Changing an existing product, even where there is presumed to be an enhancement, can be dangerous as the alterations made previously by Coca-Cola to its formulation have shown. However, Coca-Cola have successfully, and paradoxically, introduced several similar products such as diet, cherry and vanilla versions of its standard soft drink. Generally, though, introducing a new product carries greater risk and difficulty and this is exacerbated if it involves new markets or technologies. Finally, the outcomes of attempts to produce revolutionary products that overturn existing thinking and mores is extremely risky and difficult. The use of systems engineering and an holistic approach can help reduce risk and difficulty in all these types of change and becomes more applicable and important with the degree of novelty being faced. Novelty is also linked to the degree of knowledge in a given situation and is something you will consider later in this course.

Question 1

What would you conclude from the Workcenter case and your analysis in SAQ2?

Answer

The main thing that strikes me is that perhaps it is a mistake to assume that a single development process – the PDP – could apply equally to different classifications of project involving different degrees of change and risk.