3.3.2 BS 7000 model: practical

There are many more representations of design processes and issues in the academic and industrial standards literature. All are attempts to move down from the broad philosophical view of Figure 19 towards the practicalities of the design process. The ones that we will consider all come from engineering design.

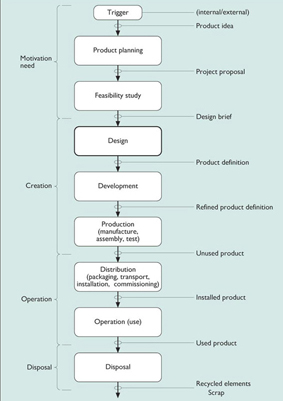

By contrast to the rather abstract and elaborate academic model of Figure 19, the British Standards BS 7000 picture of design (Figure 20) specifies a direct route from start to finish.

SAQ 7

For each of the boxes in Figure 20, identify who would be involved in each of the steps of designing and constructing a new house for yourself, and what each of the steps would comprise. (Note: some of the boxes will not apply.)

Answer

The trigger would be the need or desire for a new house (or the desire to make money if you were a developer).

The product planning would take place between you and the architect.

You might do some sort of feasibility study. For example, a few phone calls might make it clear that you cannot borrow as much money as you had hoped, so that it might not be feasible to find a solution to the original specification (swimming pool, tennis court, five en-suite bedrooms…). Something's got to go.

Then the design would be done by the architect, who might develop your favoured scheme into a final design.

This is handed on to the builders to develop and produce your house.

In this case your house will not be transported anywhere so there's no distribution.

Then you'll start to use it.

You probably will not have to worry about disposal, since the house will probably outlast you!

What's missing from the house-building process if we apply this model rigidly?

If you have experience of even modest building schemes, you will know that the architect must be there to supervise the builders, otherwise production will be a mess. And you will know that the designer sometimes makes mistakes and has to negotiate with the builder to find a solution on site. Thus there may be a loop back from production to design. None of these iterative loops is in the model (and the model contains steps which are not relevant to our example).

The model does not take into account the financial problems you will have as the cost escalates due to the specification changing. And the model does not take into account that you may have to change the specification, even quite late in the process.

SAQ 8

Suppose you were designing a passenger jet aircraft. Go through the activities listed in BS 7000 and try to say what would be going on at each stage during the design of the aircraft.

Do you think it might ever be necessary to go back to review previous steps in the design? Which ones?

Do you think the BS 7000 picture of design would describe the process adequately?

Answer

Well, I've never designed a jet aircraft, but here goes.

The trigger is presumably the desire to make money by carrying people long distances at a reasonable cost in reasonable comfort. Perhaps holiday trends or business travellers' routes have changed.

The product planning would involve deciding how many passengers, how much they might pay per seat, what distances they want to travel, what comfort they might expect and so on. An outline design specification would have to be produced, e.g. size of aircraft, number of engines. There would probably be some basic visuals produced such as sketches or images on computer.

The feasibility study would probably involve a lot of calculations to see if the aircraft was financially viable. Also many calculations to see, for example, which engines have enough power to propel the fully laden aircraft.

The design would be very complicated. I have in mind hundreds of designers sitting at computer-aided design (CAD) workstations. Everything has to be designed, right down to the personal light switches although I suppose some items might be already available 'off the shelf. I begin to think the model is rather weak here, because a huge amount of activity has to go in this box. Lots of models would be used such as CAD models; full-size mock-ups of, say, the cabin; and mathematical models.

The production would take place in a hangar, although many components would be produced elsewhere. I would expect to test the various components of the aircraft to make sure it worked properly and was safe. The various models would have been thoroughly tested during design so I shouldn't learn anything new at the first test flight!

The distribution would include delivering the aircraft, probably by flying it to the customer, and commissioning it. This might involve training the new pilots and maintenance crew.

The operation would involve the carrier flying the plane. It would also involve a great deal of maintenance, which I don't see on this diagram.

In one sense disposal might refer to the carrier selling on the aircraft to another carrier, rather like selling a car before it becomes expensive to maintain and while it still has high value. Ultimately disposal would probably take place at an aircraft scrap yard.

I think aircraft designers probably do have to go back to previous stages. For example, what happens if the product fails at the design stage (perhaps the models reveal that the required efficiency cannot be achieved) or at the production stage (the components are too expensive)? Then again, it is presumably 'back to the drawing board' and some earlier stage.

It is not uncommon for machines to fail unexpectedly when they are in operation (that is, in ways that the models did not predict). For example, sometimes all aircraft are grounded until some safety device is retrofitted. The redesign of the faulty feature also means going back in the design process. The new knowledge might also lead to better modelling and testing procedures.

I don't feel the BS 7000 diagram has represented my aircraft design process very well. It's disappointing to have 'design' as a box without further elaboration. And the suggestion that one does not 'loop back' is simply not realistic.

Even though it has the 'gold seal' of the British Standards Institution, this model has its shortcomings. But although one can criticise it, it is not completely wrong or completely useless. At some level it describes reasonably well the flow of activities in the life of developing a product. Some parts of the diagram will fit some products better than others.

So, how can the model be improved?

French's picture of design (Figure 21a) starts with a need and proceeds sequentially through formal stages with feedback. French's picture is relatively simple. For example, if you were building a house you would start with a need (somewhere to live), you would prepare and analyse a specification (the price, number of rooms, location, etc.), and you would state the problem to the architect who would come up with some conceptual designs. You would select those you liked best. It's not clear to me what embodiment of schemes means in this context, perhaps an integration of the best features of several schemes and certainly the production of drawings. These drawings would eventually have to have all the details specified for the builders, and they would be recorded as working drawings. The drawings are also used to communicate the design from designer to fabricator.

An important feature in French's model is the possibility of 'going round the design cycle'. At almost every stage, the designer must expect to revisit earlier stages to make changes so that the design 'works' lower down. French's model captures a very important part of the design process, that it is iterative in the way it cycles round until a satisfactory solution/scheme is found.

Exercise 3

What is the important feature of design captured by French's model which appears to be absent from the BS 7000 model?

Answer

French's model includes loops to earlier parts of the design process, allowing the designer to 'go round the design cycle'.

French's format is elaborated by Pahl and Beitz's picture (Figure 21b), which follows the same backbone, but adds more labels, more definition, and more feedback. At first sight this picture is harder to understand than French's.

The Pahl and Beitz model is one of the standard models in the engineering design literature. This model shows how designs are 'worked up' from loosely defined ideas into something much more definite as the process proceeds. At the beginning the designer is, understandably, unsure what the solution will be. As the design proceeds the solution (or solutions) becomes clearer.

Of course, sometimes the chosen solution path may fail; then it's back to the drawing board again round one of those loops. This model also allows the designer to go back and modify decisions made at earlier stages.

Exercise 4

Both French's model and that of Pahl and Beitz assume there is a need or a task to be fulfilled. Was this the case in the design of the plastic kettle?

Answer

While there was an established need for kettles there was no perceived need for a plastic kettle. The original, unsuccessful plastic kettle, was someone's new idea. So, in this respect there was no need or task to be performed.

However, once the company decided they should make a plastic kettle (in this case it was the idea of the Technical Director), the need for a plastic kettle is established. The task for the designer was to design one. So in this respect the models are applicable.

SAQ 9

Use the example of designing a five-bedroom house to answer this question.

In your opinion, which of the French model and the Pahl and Beitz model best represents the design process? To formulate your answer, take a list of the good and bad points of one model, alongside a list of the good and bad points of the other. Then weigh up the pros and cons, and give your considered judgement.

Answer

Deciding good and bad points is a very personal thing. Table 2 gives my lists.

| French | Pahl and Beitz |

|---|---|

| Simple, easy to understand at a glance. | Quite complicated, requires studying |

| I think this scheme would work quite well for house design. | I think this scheme might work better for house design |

| In summary, the procedure is to analyse and state the problem, sketch out some conceptual design, select those that look most promising. | All of this, but in more detail. |

| I'm not sure what 'embodiment' means for house-building – we can only do it once, so this does not seem to fit our problem. | There is more explicit optimisation in this model. That's important because there will be many trade-offs in house design. |

| Certainly the design has to be detailed into a set of drawings, so that the planning office can pass it, and the builder can build it. | Again the plans and drawings are discussed in more detail. |

| Does not allow the perceived 'Need' to change through time. Recall the discussion of design as being a process to find a problem-solution pair. | Does not allow the perceived 'Task' to change through time. Recall the discussion of design as being a process to find a problem-solution pair |

| 'Needs' often have to be changed in house building, because the loose starting specification may have no solution. | Similar remark. |

Although I found French's picture simpler and initially easier to understand, I subsequently found the Pahl and Beitz picture to be more satisfactory because of the greater detail it gives. But it depends on the purpose. If I were trying explain design to a lay person I'd probably prefer to start with French's picture. If you preferred French's picture because of its greater simplicity, that is a perfectly sensible judgement. Better to have a simple picture that you understand, than have a complex picture which you cannot understand.

It is interesting to note that by listing good and bad points in my answers to SAQ 9, I have convinced myself that none of the models we have studied is perfect. This is an important point. The models exist so that we can try to gain an understanding of how designers work; any model will either miss some key activity or will not be generally applicable. There is no single perfect model of design.