1.16.2 (3-D) - Shapes

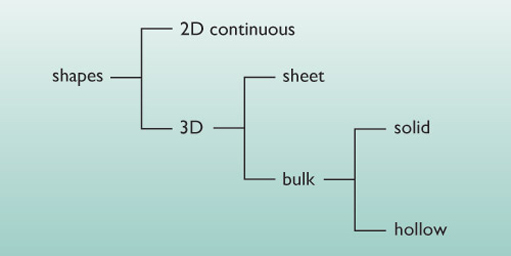

Most artefacts have profiles that vary in all three axes. Many processes are suitable for the production of 3D shapes, so we need some further breakdown of this high-level classification. We will split 3D shapes into sheet and bulk shapes.

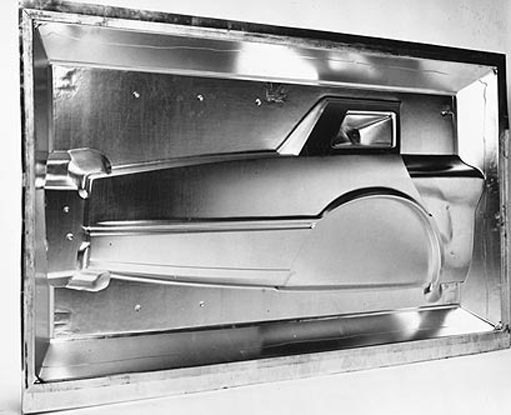

Sheet products have an almost constant section thickness, which is small compared with their other dimensions, but without any major cavities. Therefore washing-up bowls and car-body panels (before assembly) are examples of sheet products (Figure 14).

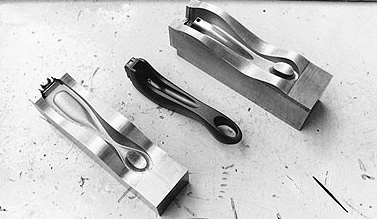

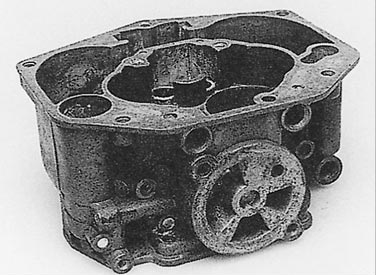

The majority of cast products fall into the category of bulk shapes, and have complex forms, often with little symmetry. If they have no significant cavities in them we will call them solid (Figure 15) but if they do have cavities, they will be classed as hollow. The cavities in hollow objects can be quite simple but they can also be more complex, involving re-entrant angles (re-entrant angle: a shape in the mould which would prevent the product from being removed from the mould after solidification), as is the case with the carburettor body in Figure 1.

One way to present such a classification is by using a hierarchical tree diagram. Figure 17 shows such a diagram for our shape classification. A similar presentation is often used to show family trees. You can see that as you progress down the tree, the shape definition becomes more and more precise. One problem generated by this classification of shape is what to do about containers and similar objects. Depending on how you view the exercise, they could be either sheet, since they tend to have uniform section thicknesses, or hollow since they often have cavities which are entirely enclosed within the artefact. We have chosen to classify them as hollow shapes.

SAQ 4

Consider the following list of components and artefacts and classify each according to the shape classification given in Classifying shapes.

-

A plastic tray used to hold the confectionery within a box of chocolates.

-

A garden hosepipe.

-

An open-ended spanner.

-

A plastic (PET) lemonade bottle.

-

A rail (from a railway track).

-

A flower pot.

Answer

-

3D sheet.

-

2D continuous.

-

3D bulk solid.

-

3D bulk hollow.

-

2D continuous.

-

3D bulk hollow.

We'll now start to look at the different classes of manufacturing processes, and their advantages and disadvantages.