1.5 Product design specification (PDS)

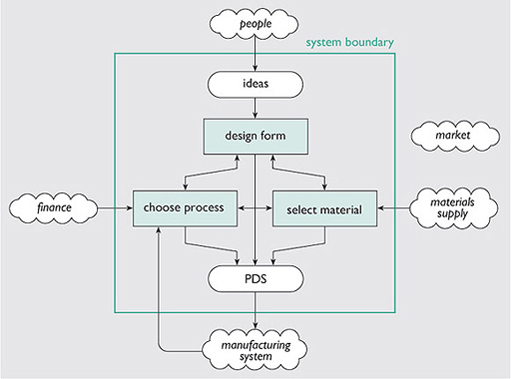

We can model the production of the PDS for a given product using a process flow diagram. One example of such a diagram is given in Figure 3.

This diagram assumes that a conceptual design for a product already exists and so concentrates on how we resolve the conflict between the shape of a product, the choice of material and the selection of a process to make it. It is clear that the output of any useful design system should be a specification detailing the way in which the product is to be made, and the standard to which it is to be manufactured. Such a specification will take into account the company's manufacturing capability, the relative performance of candidate materials, the behaviour of the market and many other technical and commercial factors.

The design activity is triggered by an idea for a product. However, there is not usually much point making a product if you can't sell it so the idea is usually coupled with information concerning the market and expressed in terms of a market need. The market need is defined by the PDS which evolves with the product, starting out as the expression of often only a vague idea but gradually increasing in complexity and detail as the product design takes shape. One approach to ensuring a comprehensive PDS is the use of a PDS checklist.

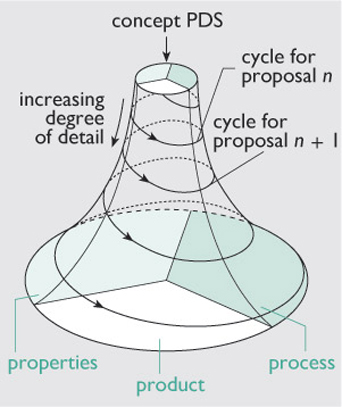

It would be a mistake to think that this checklist is a prescription to design solutions. The important thing to realise is that the PDS increases in detail as the design becomes progressively refined and each of the questions in the list will have to be asked on a number of occasions, the answers becoming more comprehensive on each iteration. One attempt to describe this iterative development of the PDS uses the spiral design model, as shown in Figure 4.

Here the idea of needing to reconsider the three areas of product shape, material properties and process capability is repeated. The increasing size of the spiral represents the fact that the amount of detailed information on the PDS grows with each iteration.

Inevitably, the parts of the PDS you consider important depend on your viewpoint and purpose. Consider, for example, the contrasting viewpoints of an engineer who works for a foundry and is trying to use up spare manufacturing capacity profitably, and an aeronautical engineer working on a new form of anti-stall flap for an airliner. Product teams with expertise in engineering design, marketing and production are required if a balance is to be maintained through the design activity. The leader of this team, often known as the product champion, will be chosen for his or her particular skills depending on the nature of the product. The one skill, however, which is always needed by such a person is leadership.