2.3.3 Expendable mould and pattern

With this type of casting, a pattern is made from a low melting point material and the mould is built around it. The pattern is then melted or burnt out as the metal is poured in. The mould has to be destroyed to retrieve the casting.

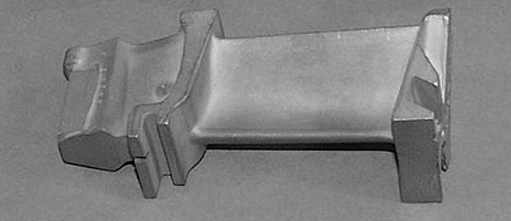

This method is used to make moulds for casting high melting-point alloys like those used for jet engine turbine blades (Figure 19). A model (the pattern) of the blade is made in wax. The pattern is then coated in a thick slurry containing ceramic particles. The slurry dries, and is then fired in an oven: this hardens the ceramic (like firing a pot) and melts out the wax, leaving a hollow ceramic mould. The metal is then poured in to the mould, which is broken away after the metal has solidified and cooled.