2.6 Casting plastics

Injection moulding is used mainly for thermoplastic polymer materials. When heated, thermoplastics do not become as fluid as metals so they cannot be shaped by gravity-fed casting methods. The injection moulding process has been developed specifically for thermoplastics.

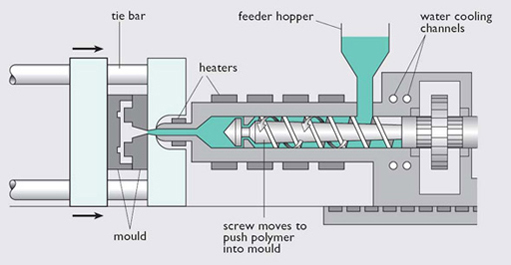

The process is illustrated in Figure 24, which shows the main features of an injection-moulding machine. The raw polymer, in the form of solid granules, falls under gravity from a hopper into a cylinder where it is propelled along by a rotating screw into an electrically heated section. As the material is heated, it softens and flows. When the cylinder contains enough material to fill the mould, the screw action is stopped. In the final stage, the screw moves axially, acting as a ram, injecting the material through a small nozzle, and down channels (runners) into the shaped cavity within a cooled mould. When heated, most polymers start to degrade before they reach a sufficiently high temperature to fill a mould adequately under gravity alone. Injection moulding imposes high shear flow rates on the polymer as it is squirted at high pressure into the die. This tends to align the long polymeric molecules and increase the fluidity of the polymer substantially. This shear thinning of the molten polymer is essential to injection moulding and can only be achieved if high injection pressures are used.