3.5 Extrusion

The principle of this process is very similar to squeezing toothpaste from a tube. Material is forced through a shaped hollow die in such a way that it is plastically deformed and takes up the shape of the die. The hole in the die can have almost any shape, so if the die is circular, for example, a wire or rod is produced (Figure 29).

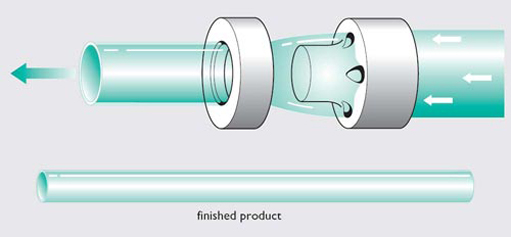

It is also possible to produce hollow sections using extrusion. In this case, the die contains a short piece (or mandrel) in the shape of the hole. This mandrel is attached to the die by one or more 'bridges'. As the extruded material encounters the bridges it is forced to separate, but it flows around the bridges and joins up again, much the same as water flowing around the piers of a bridge. Figure 30 shows such a 'bridge die'. This works successfully even for processing of solid metals.

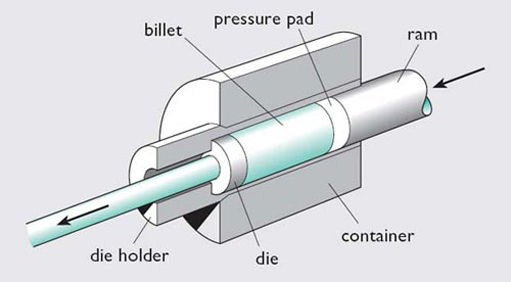

Extrusion can be used on most materials that can plastically flow as a solid, and solid metals and alloys are frequently extruded. To reduce the stresses required, and therefore the size and cost of the extrusion machine, and also to ensure hot working conditions, a metal is usually extruded at a high homologous temperature, usually between 0.65 and 0.9. This allows large changes in the shape of the material – and hence large strains – without fracture. During metal extrusion the raw material in the form of a metal ingot, known as the billet, is heated and pushed through the die by a simple sliding piston or ram.

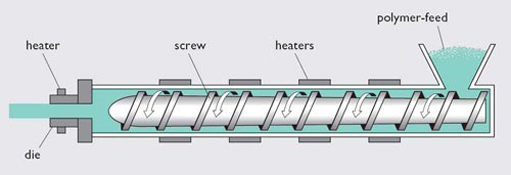

The mechanism for extruding thermoplastics is illustrated in Figure 31. In this case a rotating screw is used to transfer the raw material in the form of granules through a heated cylinder to the die, just like in the case of injection moulding for polymers. The thermoplastic granules are compressed and mixed by the screw (the granules may contain a second constituent such as colouring). The material softens and melts as the temperature rises due to heating through the walls of the cylinder, and also from the heat generated within the thermoplastic as it is sheared by the screw. The thermoplastic flows through the die and emerges with a constant cross section in the shape of the die aperture. An almost infinite variety of cross-sectional shapes can be produced.

SAQ 6

Could extrusion be used for the following products?

-

The body of a food mixer.

-

Copper pipe for a central heating system.

-

The body of a pen.

Answer

-

The body of the food mixer has a complex 3D shape, so it certainly could not be extruded.

-

Copper pipe is ideal for manufacturing by extrusion, using a bridge die to extrude the hollow shape.

-

The ink tube in the pen has probably been extruded. But the bodies, even the cheaper ones, vary in diameter along their length and are typically closed off at one end. This would suggest that the pen body is not extruded.