4.2 Cutting processes

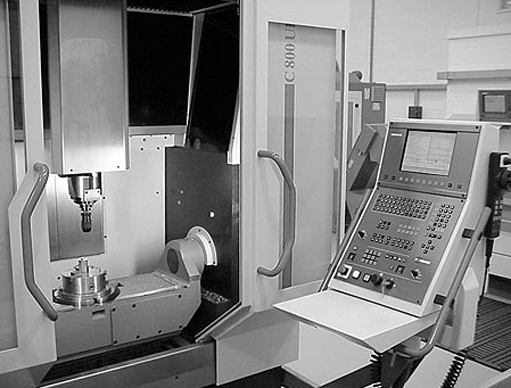

The most common cutting operations are carried out on electrically-driven machine tools; hand tools, which include electric drills, orbital sanders and the like, are also used extensively, but because of the limited number of items that can be produced economically it is not a viable manufacturing method for mass production. In industry, cutting was traditionally performed on large machines with a whole host of specialist names such as lathes, mills, broachers, shapers and many others. Each type of machine was capable of one particular method of cutting. Somewhat confusingly, these cutting machines are collectively known as machine tools and the processes are known as machining. The skilled operators of these machine tools had a significant influence on both engineering practice and labour relations for many years. However, the last few decades have seen substantial growth in the use of flexible, computer controlled machining centres (Figure 41) that incorporate both tool- and workpiece-changing facilities. The introduction of such machines, together with their reduced need for a skilled workforce to operate them, have reduced operating costs so that cutting can now be considered for production volumes that would previously be considered uneconomic.