4.4 Hardness

Hardness is related to the strength of a material and is a measure of a material's resistance to plastic deformation by scratching or indentation. Scratching the point of a pin across a material can be used to give a rough indication of hardness, but this is purely qualitative as it indicates only whether the material is harder or softer than the pin.

Hardness is one of the oldest ways of comparing the properties of materials. German mineralogist Friedrich Moh originally developed a scale for minerals which ran from 1 to 10 based on which would scratch each other. On this scale, diamond, the hardest, ranked 10 and talc, the softest, ranked 1, with other minerals in between. This scale is sometimes still used but its drawback is that the steps in between the different minerals are too large to be useful to discriminate between similar materials and the steps are not equal.

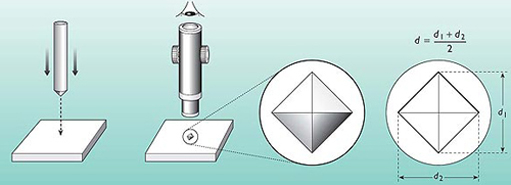

Thus, a range of other techniques to measure hardness have been developed. Some of these are based on pressing an indenter of a known geometry, such as a hardened steel ball or a pyramid, into a surface under a known load and then measuring the size of the residual impression. One of the more popular methods for both metals and plastics is the Vickers hardness test (Figure 43). This test uses a pyramid-shaped diamond to indent the surface, the size of the indent being related to the hardness; the softer the material the larger the indentation. The Vickers hardness number, HV, is the force divided by the surface area of the indentation. The values of HV for a range of materials are shown in the appendix.