4.6 Machining our gearwheel

Having described some machining processes, let's now consider whether they can be applied to the problem of making gearwheels for a food mixer. These wheels are quite complicated shapes. Could our gearwheel from the gearbox of the food mixer be made by machining? Of course, the answer must be yes because as discussed the outstanding virtue of machining is its versatility – almost any shape can be made by machining.

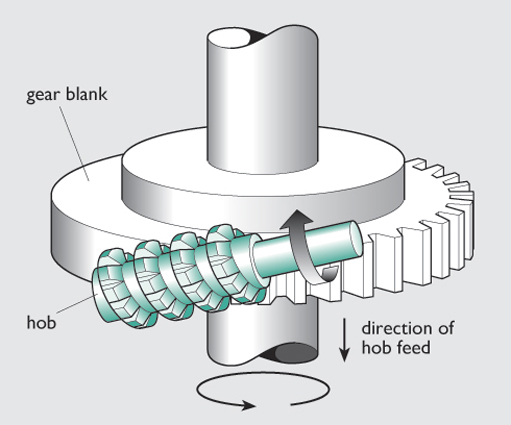

However, the complex shape means that a lot of waste material would have to be machined away if we cut it from a solid block of metal. Manufacturing a limited number of gearwheels by machining using these techniques is a labour-intensive process and would not lend itself to mass production. But for prototype manufacture, where only a few gears may be required, then this may be the most sensible option. In fact, a process called hobbing can be used for mass production of gearwheels as shown in Figure 46.

So machining can also be added to our list of candidate processes to manufacture our gearwheel. We also may need to use a machining process to finish gearwheels made by another process.

SAQ 9

If you were considering manufacturing ballpoint pens, do you think the machining option could be used?

Would machining be feasible for a mass-produced pen body?

Answer

Because of its versatility, machining could certainly be used to manufacture pens, but not as a mass-produced item. It would more likely be used as a limited production process at a high cost.