6 Making the gearwheel

6.1 Introduction

Our short review of manufacturing processes is now complete. There are many processes which have been omitted, but in the main they are variations on or adaptations to the major processes that have been examined. As you have discovered, the gearwheel that has been used as an example through this part could have been made by any of the processes, albeit with considerable difficulty in some cases! So let's see how the gearwheel is actually made.

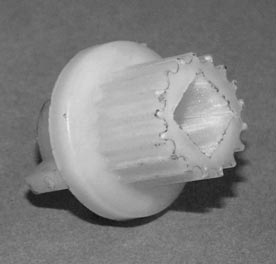

For some years, the gear in Figure 10 has been made from sintered iron powder, in which form it gives trouble-free service (Figure 49). This design replaced an earlier one in which a wheel of identical shape was made from injection-moulded nylon (Figure 50). There were some cases of fracture in the plastic wheels due to overloading in service (some owners must have liked particularly stiff dough for their pizzas), so it was decided to use a stronger material. This illustrates that redesign after service experience can be crucial to the success of a product. In this instance, actual service conditions revealed a basic flaw in the original design: the original estimate of the strength required by the gear proved to be somewhat inadequate. Stress analysis may be an exact science, but the estimation of forces from use and abuse is not and must be based on experience.