7.5 Physical vapour deposition

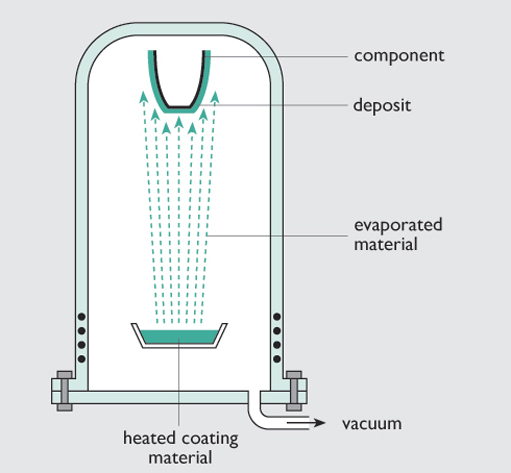

Physical vapour deposition (PVD) processes involve depositing a source material (which can either be from a solid, liquid or gas) onto the surface of the component. There may be a chemical reaction between the substrate and the coating material. One of the attractions of PVD methods is that the substrate can be at relatively low temperatures (in the range 50–500°C). Figure 56 shows a schematic diagram of the principles behind one common PVD method.

The component that is to be coated is placed in a vacuum chamber. The coating material is evaporated by intense heat from, for example, a tungsten filament. An alternative method is to evaporate the coating material by a complex ion bombardment technique. The coating is then formed by atoms of the coating material being deposited onto the surface of the component being treated.

The 'ion plating' method is used commercially to produce films of titanium nitride (TiN) such as the one used for coating kitchen knives.