Example 1 Assessing risk

An employee is working on a machine floor workshop where oil spillages could occur. The oil is slippery and the workshop floor is concrete. Use the matrix in Table 2 to rank the risk and determine the need for remedial action.

Solution

The likelihood of slipping on oil and having an accident could be quite high in these circumstances, hence the likelihood could be rated at 4 or 5. However, in a well-regulated workshop, 3 would be a reasonable value.

The question of severity is even less clear-cut. It could range from a minor bruise (rated 1) through to a fall leading to a broken leg that results in several weeks’ loss of work (rated 4).

Taking the optimistic view where the severity is considered to be 1, the risk is given by 3 × 1 = 3, requiring no immediate action but review. On the other hand, the pessimistic approach (where a fracture is a real possibility) gives a risk of 3 × 4 = 12. This calls for the implementation of controls and safe systems of work to minimise the risk. For instance, it might initiate the construction of a simple bund (a barrier to contain the spill) round the storage tanks, machines and other areas where spills might occur. This would prevent the spills from being a hazard, potentially reducing the risk to 1 × 1 – a most desirable outcome.

If experience of the workshop justifies an even more pessimistic view, the likelihood could be increased to 5 and the severity to 4. This would give a risk of 20, meaning that work should stop until improvements in practice and control measures are implemented.

Activity 1 Assessing risk

A new system has been built in a factory to provide steam for industrial cleaning operations. Steam is stored under pressure in an insulated vessel and released when needed through a valve. If this valve were to fail, the vessel would vent rapidly and cause fatalities if people were nearby. People do not normally work near the vessel but walk past it on their way to other parts of the building. Out of every 10 000 valves made, one is expected to fail during its 20-year design lifetime. How would you assess this risk?

Discussion

The valve will have a severe impact if it fails when someone is close by, so the severity of failure has to be rated at 5. Evaluating the likelihood of failure is more complex. If 1 in 10 000 valves fails during its design lifetime, it could be argued that this is a rare event (likelihood of 2); equally, the event could be classed as ‘could occur but is not common’ (ranking of 3). This gives a risk rating of between 2 × 5 = 10 and 3 × 5 = 15.

Taking the prudent approach, a rating of 15 means that the activity should not take place. In the short term, use of the vessel should cease while measures are put in place. This could involve relocating the system outside the building or in an isolated room, finding an alternative to steam cleaning or steam storage, or installing a higher-specification valve.

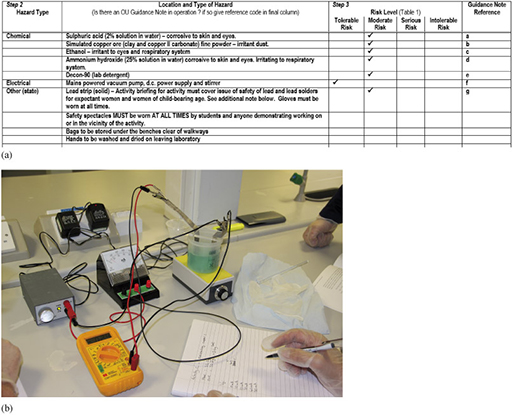

This matrix method of assessing risks is widely used in many industries. Figure 3(a) gives an example of its use in assessing one of the laboratory activities carried out by Open University engineering students during a residential school, as shown in Figure 3(b).

This type of assessment is fine for most normal workplaces. In industries where the results of an incident can be far more severe (such as oil and gas production, chemical manufacture, nuclear power generation), a more complex evaluation system is used, but it is still based on combining likelihoods and severity.

The fact that risks need to be assessed does not mean that all risks must be eliminated – indeed, that would be impossible. The aim is normally to reduce risk as far as is reasonably practicable (discussed in Section 2), which means that the risk in a particular activity or environment can be balanced against the time, trouble, cost and physical difficulty of taking measures to avoid that risk. Normally a variety of calculations are used to decide what is practicable. These are not covered in this course, but would generally include an economic assessment of reducing a risk against accepting the risk, and use an equation linking the severity of a risk and its likelihood.

When it comes to evaluating an environmental risk, the calculation might be a little different. In this scenario, evaluation would not normally cover the risk of one event or one consequence. Instead, there may be many inputs over an extended time period that go into the calculation of risk, and many outcomes – some related to harm to humans, but others concerning harm to the environment. This could include impacts on water courses, on air quality, or perhaps on neighbouring industries including farms or other food production. Such assessments might involve considering threats of serious or even irreversible damage on a large scale.