3.3 Thermal stresses

When the temperature of an object increases (say, by ΔT) it expands. According to the linear model of thermal expansion the length increase is described by

What if there is a temperature change, but some constraint prevents the proper thermal size changes? The constraint has to exert a force to prevent the change of size, so a thermal stress will be induced. There are many situations where thermal stress is made use of (for example, thermostat switches, toughened glass) or has to be worried about (cracked welds, bent rails, gas-tight seals).

Every case is in itself a problem of stress analysis, but there are essentially three kinds of situation – look at each, keeping in mind our interest in effects that might be used to make a thermal switch:

A homogeneous body (i.e. all the same stuff) subject to external constraint (fixed in some way) suffers a uniform change of temperature (it all gets hot together). This situation can cause buckling of railway lines and cracking of welds – see Box 4 Homogeneous body, uniform ΔT, external constraint.

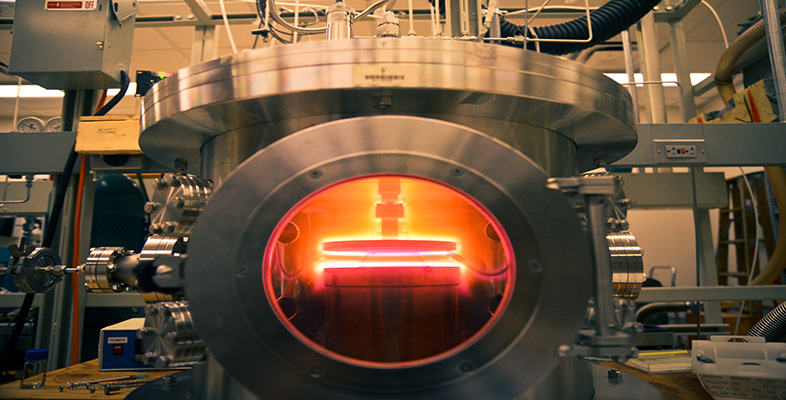

A composite body (i.e. made of at least two different materials) whose constituents have different properties generates internal constraint (each material interferes locally with the other) when T changes. Glass-to-metal seals needed in vacuum technology have to overcome this problem, as do pottery glazes – see Box 5 Composite body, uniform ΔT, internal constraint.

A homogeneous body again, but with non-uniform temperature change (i.e. different bits at different temperatures). When the temperature change is rapid the body is said to suffer thermal shock. This is what cracks glass bottles when you try to sterilise them by pouring in boiling water. How does your ceramic hob get on when your pour cold water on it? – see Box 6 Homogeneous body, non-uniform ΔT.

There are more complex cases as well – see Box 7 What about welding? for example.