1.2.2 Disposable pens and mass production

The idea of writing – setting language into a visible and permanent form through a set of symbols – is young relative to the age of our species, only a few thousand years. Among its earliest forms was the cuneiform script. The writing was a series of wedge-shaped (that's what cuneiform means) indentations in tablets of damp clay. When fired, the clay became solid, making a permanent record (Figure 6). Tonnes of these have been excavated by archaeologists and deciphered to reveal the records of the bureaucracy of the Sumerian and other Mesopotamian civilisations.

The Egyptians invented paper – the word derives from 'papyrus', the reed of the Nile which they used for paper making – so inks were needed in order to make a mark on the paper, with a 'pen' to carry the ink onto the paper in just the right quantity for legibility. In China the pen was a bamboo stick, shredded at one end to make a brush. Thanks to the skill of some brush users, calligraphy became an art form. Another simple pen was the quill, just a large feather cut across the stem at an angle and split to form a nib.

But now, as I scribble with a ballpoint pen, engineering has come onto the writing scene. Pens are manufactured and sold rather than home-made. My ballpoint pen is so cheap that when it is empty of ink I shall throw it away and get a new one – an example of how developments in engineering have led to the possibility of products that have a short life and are then discarded. As issues of sustainability grow in importance our priorities may change to make disposable items a rarity, but for now the interesting engineering question is how to make the pen so cheaply that we don't mind throwing it away.

Again, it starts with design. Obviously the thing must be designed to function as a pen, but the cost of its materials and its manufacturing process must be carefully thought about in order to get its cost very low. How is it done?

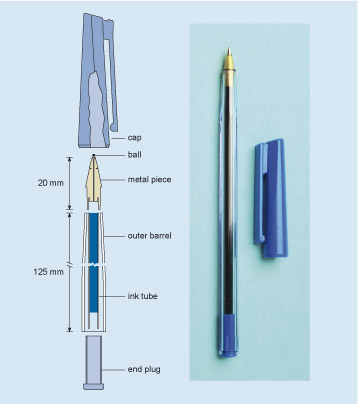

The right-hand part of Figure 7 is my pen; the left-hand part is a longitudinal section (see Engineering drawings ). It is not a unique design, and you will know that there are many similar designs in use. Indeed, it is one of the interesting features of design that many solutions can be conceived within the boundaries of a specification. What all such designs have in common is the use of a ball to transfer ink to the paper as the ball rolls across the page.

Engineering drawings

Figure 7 gives an example of a cutaway drawing: a representation of what you would see if, in this case, you were to slice the pen through the middle. It's easier to illustrate the different parts on a diagram like this than it would be using a photograph, or just words. It also allows us to show clearly the dimensions of the various parts, by marking these on the diagram, and it is used to communicate all the necessary information from the engineer who designed the component to the person who will eventually make it. You should not find diagrams like this difficult to decipher.

The pen in Figure 7 is made of six solid parts plus the ink. The outer barrel and a lid which fits over it are made of two different types of plastic. The metal piece contains the ball, and both the outer barrel and the ink tube fit its other end. The plastic end-plug prevents ink loss from the back of the pen and holds the far end of the ink tube. Each part has to be made separately and then they have to be assembled.

Activity 4 (exploratory)

- a.What are the problems that must be overcome in order for a ballpoint pen such as the one in Figure 7 to work successfully? Put yourself in the position of an engineer who has been given the basics of the design: ball, ink, and barrel, and has to solve the problems to enable it to be made. See if you can come up with three of these problems.

- b.What changes could you make to the design of the disposable pen to reduce potential environmental impact? Suggest one change that would make it easier to reuse and another that would improve recyclability.

Answer

This is what I came up with.

- a.The ball must fit sufficiently tightly that the ink doesn't ooze out. On the other hand, the ink must not be completely blocked. Also, the ball must not be damaged during the assembly process. (Maybe that counts as three problems, rather than one.)

The ink must not be too fluid or it will leak from the pen. (In many pens the end of the ink holder is open; you may have carried such a pen in a pocket, and discovered that the ink becomes more fluid at body temperature, leading to an unfortunate accident.)

The join between the metal top and the ink holder must be a good seal.

You may have come up with equally valid problems which need to be addressed for the product to work successfully.

- b.To reuse the pen a method must be provided for replenishing the ink supply. This might be done by supplying the ink tube (perhaps in combination with the end cap) in the form of a removable cartridge. The cartridge would need to be sealed before use, so that the ink does not leak: fountain pen cartridges typically use a small glass ball, or a very thin layer of plastic, for this purpose. The seal is broken when the cartridge is pushed onto the nib.

Recyclability could be improved by reducing the number of different materials involved, and making them easy to separate. The cap, outer barrel and end piece could be made from the same type of plastic. The nib section and the ball could be made from the same metal and be easily detached from the plastic parts. The ink tube would probably have to remain disposable.

You may have come up with other valid suggestions. Of course these changes may well make the pen more expensive, or compromise some other aspect of performance, so the different demands need to be weighed up against each other.

The engineering secret that enables such a thing to sell in the shops for 20 pence is to devise machinery that will make millions of pens. A million pounds invested in machinery that will make fifty million pens gives a unit cost of 2 pence per pen. That leaves 18 pence for materials, distribution costs and profit. My sums are probably in the right ballpark, but much more complete and accurate costings would be done in reality. For instance, exactly how long a period should the tooling costs be spread over? What about buildings and labour costs? And how do issues such as taxation come into the equation?

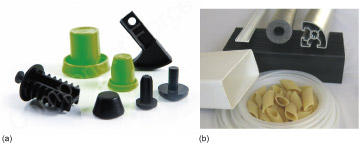

With the advent of low-cost plastic materials provided by the chemical industry, typically using oil as the raw material, such cheap, disposable objects have become open to manufacture (see Plastics and polymers ). Thermoplastics, which are a type of polymer that soften when heated and solidify when cooled, can be moulded rapidly and relatively easily to close dimensional tolerances (in an engineering context, tolerance refers to the limit of acceptable deviation from an intended value). The outer barrel, cap and end plug will be made by moulding. The ink tube is also plastic, but being of constant cross section, can be made even more rapidly by extrusion (that is, squeezing through a suitably shaped gap – think of toothpaste coming out of a tube). The tube can then be filled with ink and cut to length. Both these processes involve molten plastic being forced into a die which produces the required shape (Figure 8).

Plastics and polymers

The oil-based plastics referred to in the main text are a small subset of an important class of materials known as polymers. Polymers include a huge range of materials, both natural and synthetic, with a very wide range of properties. The one thing that they all have in common is that the molecules (two or more atoms held together by chemical bonds) from which they are made are very large, consisting of hundreds, thousands or even millions of sub-units, chemically joined together to form long chains.

A long chain can take up many different arrangements. Think of the different things you can do with a piece of string: you can stretch it out, coil it up neatly, knit it into a sheet, knot it into a net or tangle it up randomly … The possibilities are endless and each will result in a different type of structure, with different properties. The same applies to polymers: the arrangements that the chains adopt are influenced by the length of the chain, by the chemical nature of the sub-units and by the processing conditions, and can lead to materials with very different physical properties. A few examples are shown in Figure 9.

The correct chemical name for the PE in HDPE (and its close relation LDPE) is 'polyethene', but you will also find it referred to as 'polyethylene' (an older but commonly used version) or 'polythene' (a trade name). All three names may be used in this course.

The term 'plastic' tends to be reserved for synthetic polymers derived from oil, such as polyethene (PE, usually sub-divided into high density HDPE and low density LDPE) or polyvinylchloride (PVC). Many of these are thermoplastics: they soften when heated and solidify when cooled, making them relatively easy to process. The word plastic actually pre-dates the discovery of polymers by a few centuries, and originally referred to the capacity of certain materials, such as clay or wax, to be moulded or shaped. 'Plastic', in this original sense, describes the properties of some, but not all, polymer materials.

The writing end is more tricky to make. A typical ballpoint pen will inscribe many kilometres of writing during its use, hence the material for the ball needs to be hard, so that it does not wear away too quickly. Fortunately, tungsten carbide (a hard ceramic material) is often used for ball bearings, and these can be made to a very close tolerance. That is, they can be made with a high degree of accuracy, with very little variation in diameter observed across a batch of ball bearings. Thus the balls for the pen can be bought ready-made from a ball bearing manufacturer.

The pen maker has to make the metal piece to receive the ball with just enough clearance to allow the ink to flow round the ball. It can be turned on a lathe from a metal bar. If this were to be done by hand, the pen would become expensive simply because of the labour cost involved. So it is likely that a computer-controlled lathe would be used. To enable the machining to be done at high speed, for rapid output, a material that can be easily cut, and that is not brittle (so it won't chip) must be chosen. Brass (an alloy of copper and zinc) meets this requirement, but is quite an expensive material. The design/costing exercise thus has to balance material costs against tooling costs. The balance will depend on the quantity of brass used and the time needed to machine each piece. The metal piece that holds the ball at the end of my cheap ballpoint pen is indeed a yellowish metal: brass.

A production sequence is needed that will provide the top metal part, insert the ball and reduce the diameter of the end to trap the ball (Figure 10). Finally, all the parts have to be assembled. Once again, a machine must do this in order to maintain a high production rate. So a critical factor is that all parts of each sort must be interchangeable. It would be useless, for example, if a batch of end plugs that came to the assembly machine were too big to fit into the outer barrel. So this brings us on to the key part of these case studies: mass production.