3.3.2 Innovation in processing

An example of development and innovation in processing is the story of iron and steel. Although wrought iron was well known for centuries (since the so-called Iron Age), it needed heavy working by blacksmiths in order to shape it into usable products. It was also rather soft and susceptible to corrosion (rusting). Harder products such as swords could be made by repeated working and folding, but steel as we know it today was unknown until the 1850s.

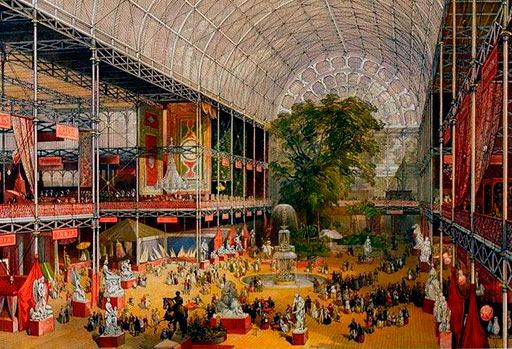

Large-scale production of iron was only achieved relatively recently, by Abraham Darby in the 1750s (see The Darby family and cast iron ). So-called 'cast' iron became the structural basis of the first phase of the British Industrial Revolution, being widely used for large structures such as bridges (e.g. the Coalbrookdale bridge: Figure 44), buildings (e.g. the Crystal Palace: Figure 45) and for a host of applications in industrial machinery.

The Darby family and cast iron

The development of cast iron as an engineering material is very much the story of the Darby family, who developed large-scale methods of making this valuable material.

The key step in smelting iron ore to raw metal is the reducing agent used: a reducing agent is a chemical that reacts with the iron oxides in the ore to release the iron in metallic form. Charcoal (produced by partial burning of wood) had been used for two millennia for making wrought iron in small quantities, but it was the development of the coal industry that prompted Darby to try coke (made by controlled heating of coal in the absence of air) as a more effective fuel than charcoal. This development in 1708 led to the cast iron industry founded on the banks of the River Severn at Coalbrookdale. Coal itself cannot be used for the iron-making process because of impurities such as sulfur, which impair the qualities of the iron produced. Consequently it was coke that was the key step in developing a furnace capable of making cast iron on a large scale. The Old Furnace (shown in Figure 46) was the forerunner of the modern blast furnace, and was used to make the members of the first cast iron bridge, spanning the River Severn at Coalbrookdale (Figure 44).

Coke, together with limestone and iron ore, was fed in at the top and fueled by air fed in lower down (not shown); the molten cast iron was extracted at the base. The air was fed in by tuyères – pipes leading in about halfway up the furnace, which 'blasted' a draught of hot air to the charge. The mechanical properties of the coke were important because the mixture had to be both porous enough for the reduction to proceed smoothly and strong enough to resist the weight of material above. The molten iron could then be tapped and run directly into moulds. This furnace was especially important for making the key parts of steam engines. Some of the carbon of the coke dissolved in the iron (about 4%), which gave the material its relatively low melting point, but also made it very brittle.

It was a key discovery: that the amount of carbon present in the iron controlled not only its melting point but also its properties. By controlling the addition of carbon through the use of coke, a form of iron was made that could be cast on an industrial scale. When we talk of iron as the material used for a range of engineering use, we are almost always referring to an alloy of iron that contains some carbon.