Week 8 Readings

| Site: | OpenLearn Create |

| Course: | Chinese Ceramics: Kilns to Smart Materials |

| Book: | Week 8 Readings |

| Printed by: | Guest user |

| Date: | Wednesday, 18 February 2026, 4:25 PM |

Table of contents

- 1. Hands-on workshop (optional)

- 2. Watch a video: Crafting Luxury The Secrets Behind China's Exquisite Porcelain

- 3. Watch a vdieo: Step into the millennium-old porcelain capital, witness the most beautiful porcelain, and experience the charm and elegance of a thousand-year-old porcelain culture! — Jingdezhen [CCTV Documentary]

- 4. Capstone Submission

- 5. Path A: Hands-on Workshop Hub (Full Details)

- 6. Path B: Home Video-based Making

- 7. Career and Job Market Overview

- 8. Acknowledgements

1. Hands-on workshop (optional)

This course includes an optional hands-on ceramic workshop pathway connected to Shaanxi, China. The workshop supports learners who want to implement a capstone work in a studio environment and strengthen practical skills in forming, surface design, glazing, firing strategy, and professional documentation.

Why the workshop details are hosted on IULS Moodle

OpenLearn Create focuses on open learning content. The workshop includes operational details such as:

- registration and capacity management

- preparation requirements and studio safety

- travel guidance and on-site scheduling

- updates that may change by season or local conditions

To keep that information accurate and manageable, all workshop logistics are hosted on IULS Moodle.

Remote alternative pathway

If you cannot travel, you can complete an equivalent learning outcome locally:

- produce the work (or prototype) in a local studio

- submit a documentation set (6+ photos with text descriptions)

- submit a 400–600 word artist statement (English or Chinese)

- participate in peer critique and Week 8 reflection

2. Watch a video: Crafting Luxury The Secrets Behind China's Exquisite Porcelain

Transcript: Watch a video: Crafting Luxury The Secrets Behind China's Exquisite Porcelain

This video documents the production process at Shenzhen Guoci Yongfengyuan Porcelain Industry Co., Ltd.

Guoci Yongfengyuan was established during the Qianlong era of the Qing Dynasty (1795) and has been passed down through five generations. It is a comprehensive ceramic enterprise integrating raw materials, research and development, design, production, marketing, and the promotion of ceramic culture.

The company employs over 4,000 people and produces household porcelain, gift porcelain, hotel porcelain, and collectible porcelain. With an annual output of approximately 30 million pieces, its products are exported to more than 40 countries and regions. The company has also undertaken research and design work for porcelain used at major national events.

Design and Research

Decal R&D Laboratory

Designers develop ceramic patterns and decorative styles.

Printing Workshop

Decorative designs are prepared for transfer application.

Glaze Formula Laboratory

Glaze recipes are tested and adjusted. Flow rate tests are conducted to ensure proper glaze consistency.

Raw Material Processing

Grinding and Mixing

Raw materials are ground and mixed in industrial grinders.

Bone China Grinding Workshop

Raw materials undergo ball milling, vibration screening, and filter pressing. The processed slurry is stored in underground tanks for thorough mixing and aging.

White and black slips are tested for flow rate. Slip from storage tanks is dewatered using filter presses, and clay cakes are removed for further processing.

Forming and Molding

Isostatic Pressing

Ceramic isostatic pressing machines enable automated production from feeding to forming.

Mold Manufacturing Workshop

Plaster molds are produced and stored. Plaster slurry is poured into molds, and vent rods are inserted to assist air release during demolding. After approximately three minutes, the plaster solidifies and the mold is trimmed.

Slip Casting

Slip is poured into plaster molds. After setting, excess slip is poured out. Once sufficiently firm, the molds are opened and the formed pieces are removed.

Jiggering Forming Workshop

Mechanical forming methods shape round ceramic forms.

Drying Ovens

Formed pieces are dried before firing.

Firing Processes

Bisque Firing

Ceramics are bisque-fired at temperatures between approximately 980°C and 1280°C. This process increases the mechanical strength of the ceramic body and reduces damage during glazing.

After bisque firing, pieces undergo inspection.

Glazing

Surface Preparation

Polishing and washing improve glaze adhesion.

Glaze Spraying

Interior glaze is applied to specific forms, such as liquor bottles.

In some cases, the ceramic body is preheated to approximately 100–120°C before glaze spraying. This promotes better glaze adhesion. After glazing, pieces undergo high-temperature glaze firing, typically above 1300°C.

After glaze firing, products are inspected again.

Decoration and Gold Application

Decal Application

Ceramic decals are applied to the glazed surface. After decal application, the pieces are fired again.

Gold Tracing

Artisans apply gold decoration using gold paste containing real gold. The uniformity of gold lines is inspected using focused lighting.

After gold decoration, the pieces undergo an additional firing.

Quality Control

Final Product Inspection

Finished products are carefully examined for defects.

Heavy Metal Testing

Laboratory testing ensures compliance with safety standards. An Atomic Absorption Spectrophotometer is used to measure the presence of metallic elements such as lead and cadmium.

Samples with decals are soaked in 4% acetic acid solution to produce leachate. The leachate is then analyzed to determine heavy metal content.

Packaging

Products that do not meet quality standards are discarded. Approved products are sent to the packing workshop for final packaging.

3. Watch a vdieo: Step into the millennium-old porcelain capital, witness the most beautiful porcelain, and experience the charm and elegance of a thousand-year-old porcelain culture! — Jingdezhen [CCTV Documentary]

4. Capstone Submission

Submit the following

-

Capstone proposal (use the template below)

-

2–3 sketches (image + short text description)

-

Risk plan (top 2 risks + mitigation)

-

Documentation plan (6-view list + key facts)

Capstone Proposal Template (copy/paste)

Title:

Concept (120–180 words):

Historical anchor (60–120 words): What tradition/form/glaze or visual logic are you referencing, and why?

Form plan: shape, approximate dimensions, how it is viewed/used

Surface plan: glaze/texture/decoration + how it supports meaning

Material/process plan: clay body category + forming method + firing plan (if known)

Property/performance note (optional): durability/heat resistance/response concept (no engineering required)

Risk management: top 2 risks + mitigation

Documentation plan: 6 required views + captions + accessibility text

5. Path A: Hands-on Workshop Hub (Full Details)

Path A is an optional China-based study tour and hands-on ceramics workshop in and around the Yaozhou kiln region (near Tongchuan, Shaanxi), with study visits in Xi’an and surrounding areas. The workshop combines:

-

Site-based learning (kiln ruins, heritage interpretation, museum objects)

-

Studio training with a National Intangible Cultural Heritage (ICH) master and teaching team

-

Firing your own work (subject to kiln schedule and safety procedures)

-

Portfolio-ready documentation aligned with Weeks 6–7 (six-view standard, captions, label, maker statement, risk log)

Important: Registration, fees, dates, visa guidance, health & safety policies, consent forms, and the final submission are hosted in the IULS Moodle Workshop space. This OpenLearn unit provides the learning structure; Moodle manages participation and assessment logistics.

Path A is suitable if you want:

-

in-person technique learning and critique

-

a guided introduction to Yaozhou kiln heritage

-

a complete “field-to-studio” experience you can document for applications and professional portfolios

-

a collaborative learning community during the trip

You do not need advanced ceramics experience. Beginners are welcome if you can commit to careful practice, safety, and documentation.

Learning goals (what you will be able to do)

By the end of Path A, you will be able to:

-

Apply evidence-based object reading in museum and site contexts (observe → suggests → question).

-

Use a structured workflow to plan, make, and finish a ceramic work under supervision.

-

Practise at least one Yaozhou-related technique (e.g., carving/decoration planning, surface control).

-

Document your making and learning using a portfolio pack (six views + captions + label + maker statement + alt text).

-

Reflect on iteration: diagnose results and propose a revised version based on evidence.

Format and location

Core locations

-

Xi’an: museum-based learning and cultural study visits

-

Yaozhou kiln region (near Tongchuan, Shaanxi): kiln heritage visits + studio learning + firing

5.1. 14-day Itinerary

A 14-day immersive study program based in Shaanxi (Xi’an + Tongchuan/Yaozhou Kiln area, Chenlu Ancient Town), combining:

-

Cultural adaptation + museum study in Xi’an (Days 1–2)

-

7-day deep immersion in Yaozhou ceramics in Tongchuan/Chenlu (Days 3–9)

-

Xi’an historical/cultural extension and reflection (Days 10–13)

-

Departure + safe packing of fired work (Day 14)

Best timing: The plan recommends May or June for comfortable weather and outdoor-friendly practice.

Day-by-day schedule

Day 1 — Arrive in Xi’an: Welcome & Orientation

Morning / Afternoon

-

Airport pickup; check in to a city hotel; rest and adjust after travel.

Evening

-

Welcome dinner featuring Shaanxi cuisine.

-

Briefing / opening ceremony: full itinerary, safety notes, and cultural etiquette.

Daily focus: settle in, reduce jet lag, prepare energy for intensive days ahead.

Day 2 — Xi’an Museum Study + Free Exploration

Morning

-

Guided deep visit (3–4 hours) to Shaanxi History Museum Qin-Han Hall or Shaanxi Archaeology Museum (choose one).

Afternoon

-

Free time for time-zone adaptation and exploring Xi’an at your own pace.

Figure 1 Qin-Han branch of the Shaanxi History Museum

Day 3 — Travel to Tongchuan / Chenlu: First Encounter with Yaozhou Kiln

Morning

-

Travel from Xi’an to Tongchuan / Chenlu Ancient Town; check in.

Afternoon

-

Guided learning visit: Yaozhou Kiln Museum, Tang–Song kiln sites, and Tang sancai site to understand the kiln’s long history and major achievements.

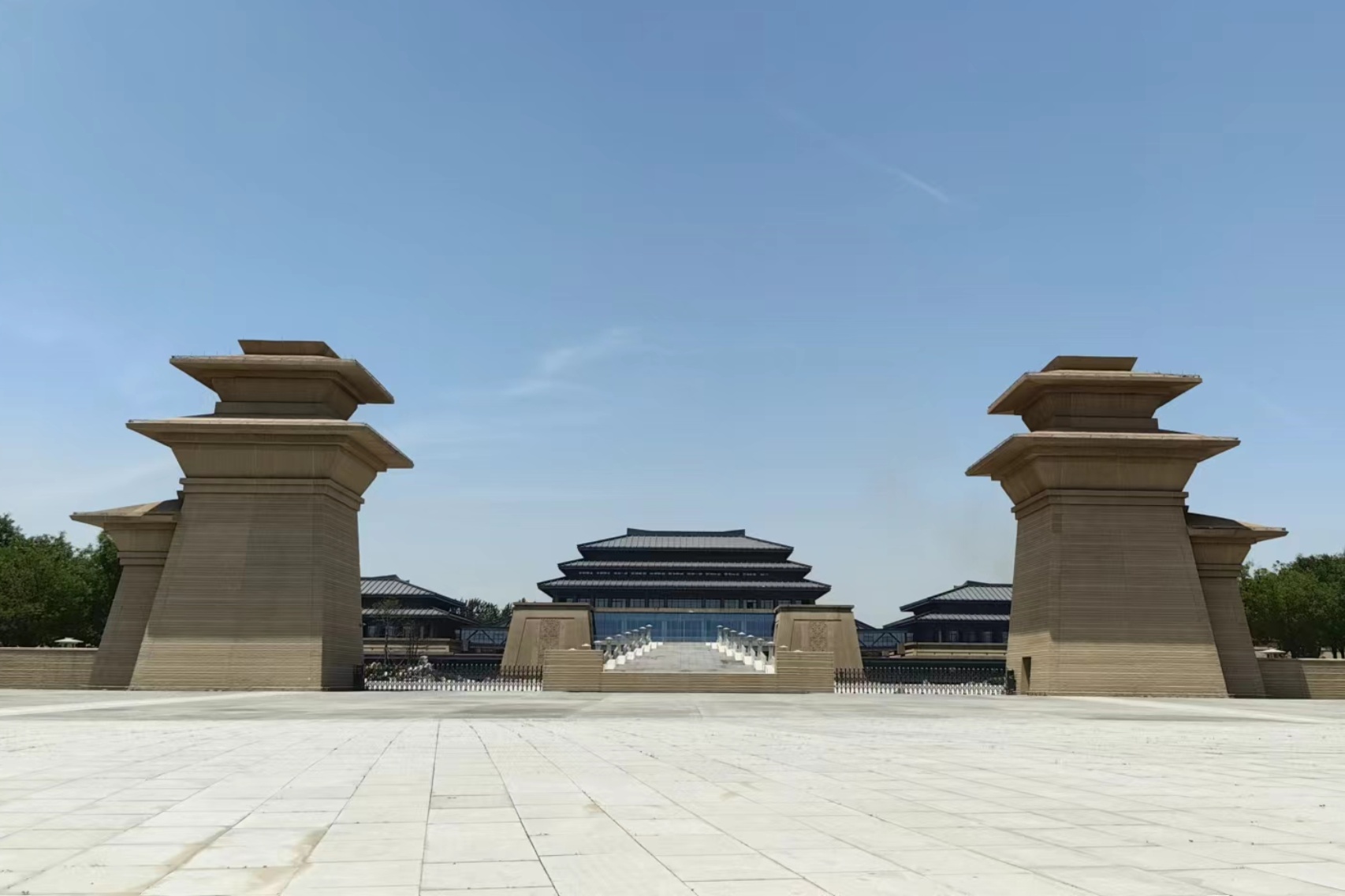

Figure 2 Yaozhou Museum

Day 4 — Chenlu Deep Visit + Studio Familiarisation

Morning

-

Deep tour of Chenlu Ancient Town (including local museums and workshops).

Afternoon

-

Workshop base orientation: meet hosts, understand studio workflow, safety, and local tools/materials.

Community element

-

Cross-cultural making & sharing (international learners co-create and exchange perspectives).

Days 5–9 — 5 Days of Ceramic Practice Courses (6–8 hours/day) + Showcase

These are your core studio days: intensive hands-on learning, daily practice, and guided critique.

Daily structure (recommended)

-

Block A (2–3 hours): Wheel-throwing / forming

Learn clay preparation and throwing fundamentals (centering, opening, pulling forms). -

Block B (2–3 hours): Carving / Yaozhou motif practice

Practice classic patterns such as peony, lotus, wave motifs; understand the Yaozhou “knife into clay” aesthetic. -

Block C (process rotation): Full ceramic workflow (17 steps)

Experience the full chain from raw material handling through forming, trimming, carving, bisque, glazing, and firing—building a complete mental model of ceramic production. -

Master class (scheduled within Days 5–9): Intangible Cultural Heritage (ICH) inheritor session

On-site teaching + dialogue with master artisans; demonstration and close observation of high-level skills. -

High-temperature firing experience

The plan highlights high-temperature kiln firing (1320°C) as part of the process experience. -

Mini exhibition / outcomes showcase

The program includes outcomes display as part of the practice block.

Figure 3 A master making ceramics

Day 10 — Return to Xi’an: Ancient–Modern Culture Connection

Morning

-

Return from Tongchuan to Xi’an; hotel check-in; reset.

Evening (choose one)

-

Beilin Museum (Stele Forest Museum) or Datang Everbright City (modern cultural district) to experience “ancient art meets contemporary life.”

Day 11 — Terracotta Army Research Visit (Optional add-on)

-

Visit the Qin Shi Huang Terracotta Army Museum to study Qin-era art, technology, and military culture.

(Optional project; separate budget may be required.)

Day 12 — Traditional Culture Experience Day (Optional modules)

Choose a set of cultural practice experiences, such as:

-

Calligraphy

-

Tea ceremony

-

Hanfu experience (traditional clothing)

Day 13 — Closing Reflection + Farewell Dinner + Certificates

Morning

-

Reflection sharing session: learners present what they gained across 14 days—skills, cultural learning, cross-cultural insights.

Evening

-

Farewell dinner; certificates and souvenirs.

Day 14 — Departure + Safe Packing of Ceramic Works

-

Pack luggage with support to ensure ceramic works are safely protected for travel.

-

Free time for local cultural/creative souvenirs (optional).

-

Airport transfer to Xi’an Xianyang International Airport; support with check-in and departure.

Fee:

The estimated cost for the 14-day China hands-on study tour is around USD 1,250, depending on exchange rates. This budget is calculated for a group of up to 20 participants and is designed as an all-in local package, covering in-country transport (coach with driver, fuel and tolls), accommodation (shared twin rooms in a standard hotel), meals (daily breakfast plus two main meals, with both Chinese and Western options), ceramics practice tuition and materials (5 days of hands-on making, including clay, carving/decoration and firing for a set number of works), course and activity costs (master instruction, study visits/entry tickets where applicable, and local learning support), and basic insurance and incidentals.

Please note that international flights, visa fees, personal spending, and optional add-ons are not included, and the per-person cost may increase if the group size is smaller than 20.

The programme also includes service and safety arrangements such as coordinated logistics, professional guidance during study visits, an emergency plan, and a 24-hour contact mechanism for participant support.

5.2. What you must prepare before you travel (Required)

Complete these items before arrival to ensure safe and productive learning:

1) Learning plan (from Week 7)

-

Choose your project direction (tableware OR vase)

-

Identify two risks + mitigation actions

-

Prepare a one-sentence limitation statement (ethical clarity)

2) Documentation plan (from Week 6)

-

Prepare your six-view shot list

-

Draft two captions and one alt text example

-

Draft a first version of your maker statement (120–160 words)

3) Required admin steps (in Moodle)

-

Registration form

-

Payment/fees

-

Passport/visa guidance acknowledgement

-

Health & safety + consent forms

-

Emergency contact details

-

Photo/video consent options

-

Workshop submission enrolment

(All admin steps are completed in Moodle.)

What to bring (practical checklist)

Essentials

-

passport/visa documents (as required)

-

suitable studio clothing (closed shoes; clothes that can get dirty)

-

notebook or digital notes system

-

phone/camera for documentation

Recommended

-

basic protective items (mask if you are sensitive to dust; follow local studio rules)

-

small measuring tape/ruler (for scale notes)

-

a folder for printed travel/insurance documents

-

personal medication and any required health items

Do not bring

-

restricted materials or tools not allowed by the workshop site (see Moodle rules)

5.3. Assessments and submissions (Moodle Workshop)

Path A submissions are completed in the IULS Moodle Workshop (not on OpenLearn). You will submit a portfolio-style pack aligned with Weeks 6–7.

What you will submit (Path A Workshop Pack)

Part A — Field + site learning

-

Site evidence notes: 5 observations + 2 “may suggest” hypotheses

-

One 90-word label for a museum/site object (with Harvard reference)

Part B — Studio process

3) Process log (bullet timeline: what you did each day)

4) Risk log (at least 2 risks + mitigation + evidence)

Part C — Portfolio pack (final)

5) Six-view documentation (photos or a complete plan if photos limited)

6) Captions (6 one-line captions)

7) Maker statement (120–160 words)

8) Process + limitations note (60–90 words)

9) Alt text for 2 images (1–2 sentences each)

Part D — Reflection

10) 250–400 word reflection: what changed between your plan and your results, and what you would revise next.

How grading/feedback works (overview)

-

You will receive feedback through the Moodle Workshop process (peer + instructor, depending on settings).

-

The focus is on evidence-based learning, safe practice, clear documentation, and reflective improvement.

Professional value (why this helps careers)

Completing Path A gives you a strong set of outputs for:

-

portfolio submissions (residencies, workshops, courses)

-

studio applications and collaborative projects

-

education/outreach roles (clear labels and public summaries)

-

communicating design decisions (form/surface/process) to international audiences

5.4. How to join (Path A)

To attend Path A, you must use IULS Moodle for registration and workshop submission:

- Open the IULS Moodle link for Week 8 Path A

- Path A IULS Moodle link: https://class.lifesci.education/mod/feedback/view.php?id=14530

- Please send an email to support@lifesci.education to apply for an IULS Moodle account first.

- Complete the registration form + required documents

- Complete the pre-travel learning plan and upload the required drafts

-

Attend the workshop and submit your Workshop Pack in Moodle

6. Path B: Home Video-based Making

This pathway is for learners who will not travel to China. You will implement a small ceramics project at home using the video resources and a safe, realistic workflow. You may work with clay if available, or complete a prototype and planning submission if firing is not possible.

Step 1 — Choose ONE project

- Option 1: Tableware (cup / bowl / small plate)

- Option 2: Vase (coil-built or slab-built recommended)

Step 2 — Watch videos (select 3–6)

Watch at least 3 videos from the Week 7/8 home-making list and take notes:

- method used (pinch/coil/slab)

- joining strategy (score/slip/compress)

- drying strategy (how they prevent cracks/warping)

Step 3 — Make or prototype

- If you have clay: complete the forming + controlled drying steps

- If you do not have clay/kiln: complete a full plan + prototype mock-up + documentation plan (still valid)

Step 4 — Submit your Home Implementation Pack

Submit:

- Home-making plan (250–350 words)

- 2–6 photos of process/prototype (or sketches) + text descriptions

- Risk log: top 2 risks + mitigation

- Documentation plan: 6 required views for a final piece

- Short reflection (150–200 words): what changed in your making decisions after watching videos

Food safety note (important):

Functional tableware typically requires proper kiln firing and appropriate glaze/body maturity. This course does not certify food safety. Focus on safe planning, evidence-based learning, and clear documentation.

7. Career and Job Market Overview

This section is an educational overview to help learners understand possible pathways. Job titles and demand vary by country/region, and no employment outcome is guaranteed.

A. Art ceramics and creative industries

- studio practice and teaching (community studios, workshops)

- product development and craft-based small production

- cultural institutions support (museum education, exhibition assistance, collections support)

B. Industrial ceramics and materials-related pathways

- ceramic manufacturing and process roles (forming, firing, quality control)

- advanced ceramics support roles (testing, prototyping, production coordination)

- supply chain contexts for sensors, insulators, wear parts, and harsh-environment components

C. Transferable skills strengthened by this course + workshop

- object-based reasoning and evidence-based interpretation

- planning and risk management for making processes

- professional documentation (images + specs + writing)

- cross-cultural communication and critique practice

D. Neutral career preparation tips

- build a portfolio with process + final outcomes

- create repeatable “process cards” (steps, risks, results)

- if aiming for industrial pathways, strengthen basic materials literacy and quality mindset

8. Acknowledgements

This course includes third-party materials (images and videos). Every effort has been made to ensure that these materials are used with appropriate permission and that they are acknowledged correctly. If you believe any content has been used without appropriate permission, please contact the course team so we can review and, if needed, remove or replace it.

Figure 1 Qin-Han branch of the Shaanxi History Museum © Wikimedia

Figure 2 Yaozhou museum © Shaanxi University of Science and Technology

Figure 3 A master making ceramics © Shaanxi University of Science and Technology