Use 'Print preview' to check the number of pages and printer settings.

Print functionality varies between browsers.

Printable page generated Thursday, 5 February 2026, 5:54 AM

Study Session 6 Operation and Maintenance of Water Treatment and Supply Systems

Introduction

Urban water supply involves a number of components: the water source, treatment plant, service reservoirs and the distribution system. Water utilities are responsible for the operation and maintenance of water treatment plants and distribution networks, crucial for ensuring reliability and quality of supply. This study session begins by considering the organisational structure of a typical water utility in Ethiopia, and then concentrates on how adequate operation and maintenance of the water treatment and supply system can be undertaken through proper planning and implementation. You will also consider measures that may be put in place to cope with natural disasters such as floods.

Learning Outcomes for Study Session 6

When you have studied this session, you should be able to:

6.1 Define and use correctly all of the key words printed in bold. (SAQ 1.1)

6.2 Describe the organisational structure of a typical water utility in Ethiopia. (SAQ 6.2)

6.3 Describe the main features of successful operation of a drinking water treatment and supply system. (SAQ 6.3)

6.4 Describe how effective maintenance can be achieved in a drinking water treatment and supply system. (SAQ 6.4)

6.5 List options for coping with flooding in order to protect water supply. (SAQ 6.5)

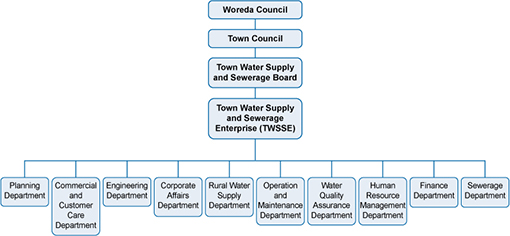

6.1 How water utilities are structured

Water utilities are part of the organisational structure for water supply in towns and cities. In Ethiopia each woreda has a Council, and each town in the woreda has its own Town Council. Under each Town Council there is a Town Water Board, and under it is the water utility, which may also be termed the Town Water Supply Enterprise. In some towns the water utility is also responsible for the collection and disposal of sewage, in which case it is referred to as the Town Water Supply and Sewerage Enterprise (Figure 6.1) and reports to the Town Water Supply and Sewerage Board. The water utilities have a duty to provide the water supply (and sewerage services) promptly, at appropriate cost, and with a high quality.

The Town Water Board is a committee made up of individuals who are specialists in water treatment and supply, representatives of other sector offices such as Health and Education, and other stakeholders (in this context, representatives of people who would be affected by the water utility’s actions). Importantly, two members of the Board are democratically elected community representatives. At least one of these has to be a woman. The term of office of the Board members is five years. The function of the Board is to ensure the effective performance of the water utility. In particular it is responsible for ensuring that the water delivered to the public conforms to quality standards. The Board is also responsible for determining the utility’s vision, mission, aims, objectives and values, together with approval and monitoring of the utility’s budget and work programme, recruitment of the utility’s General Manager, and approval of appointment of Heads of Department.

A water utility may have several departments (Figure 6.2):

- The Planning Department plans for the growth in services provided.

- The Commercial and Customer Care Department handles queries and complaints from commercial and domestic customers.

- The Engineering Department is responsible for major engineering works, such as refurbishment or expansion of facilities.

- The Corporate Affairs Department takes care of public relations and communications such as publicity campaigns to encourage efficient use of water.

- The Rural Water Supply Department ensures that water supply is extended to cover the rural population.

- The Operation and Maintenance Department ensures the smooth running of the water treatment and supply system.

- The Water Quality Assurance Department monitors the quality of delivered water to ensure that it is up to standard.

- The Human Resource Management Department looks after the recruitment and training of staff.

- The Finance Department manages the water utility’s budget and makes sure that all financial transactions are recorded, and that revenue is collected for water supplied.

- Finally, if relevant, the Sewerage Department looks after the sewer network and sewage treatment. (Note that sewage is the water-carried faecal waste from toilets, sewers are the pipes carrying this waste and sewerage refers to the infrastructure that conveys sewage. It encompasses components such as receiving drains, manholes, pumping stations and screens.)

While all the above departments are important, an effective and efficient Operation and Maintenance Department is vital to ensure that people receive good-quality water continuously each day. This function will be the focus of the next section.

6.2 The basics of operation and maintenance

Operation and maintenance of a water supply system refers to all the activities needed to run the system continuously to provide the necessary service. The two words are very frequently used together and the abbreviation ‘O&M’ is widely used. The overall aim of operation and maintenance is to ensure an efficient, effective and sustainable system (Castro et al., 2009). ‘Efficient’means being able to accomplish something with the least waste of time, effort and resources; ‘effective’ means being successful in producing the intended result; and ‘sustainable’ means able to be maintained at the best level over time – in this case, the supply of water.

6.2.1 Operation

Operation refers to the routine activities and procedures that are implemented to ensure that the water supply system is working efficiently. The activities that contribute to the operation of a water utility are undertaken by technicians and engineers who have responsibility for controlling the functions of the system (Figure 6.3).

The components of the system that they look after, such as the treatment plants, process units and all the equipment and facilities (for example, offices and laboratories) are called the assets. For each asset there will be operating guidelines to follow. For instance, a water pump should only be operated for a limited number of hours per day and this must not be exceeded, otherwise it will be exposed to overheating and eventually to failure. The pump should also be run long enough to fill the service reservoir (which you learned about in Study Session 1). If not, there will not be enough water for distribution to customers.

What are service reservoirs?

They are reservoirs of water that serve to balance the fluctuating demands of users. They also serve as a back-up supply in case there is a breakdown at the water treatment plant that cuts the production of clean water.

6.2.2 Maintenance

Maintenance (Figure 6.4) refers to planned technical activities or activities carried out in response to a breakdown, to ensure that assets are functioning effectively, and requires skills, tools and spare parts (Carter, 2009). There are two types of maintenance:

- Corrective or breakdown maintenance: this is carried out when components fail and stop working. Breakdown is common in many utilities in Ethiopia and occurs as a result of poor preventive maintenance (explained next).

- Preventive maintenance: this is a regular, planned activity that takes place so that breakdowns are avoided. Examples of preventive maintenance would include servicing of equipment, inspecting equipment for wear and tear and replacing as necessary, cleaning and greasing moving parts of equipment, and replacing items that have a limited lifespan. Preventive maintenance is important because it ensures that the asset fulfils its service life. It also prevents crises occurring and costly repairs (in terms of time and money) being needed.

If you consider the example of the pump mentioned in Section 6.2.1, regularly checking the electrical parts, the components of the switch/operating board and inspection of power lines are tasks that can be regarded as preventive maintenance. If the pump fails due to operational problems or lack of preventive maintenance, it will have to be repaired or replaced – an example of breakdown maintenance.

Preventive maintenance ensures that the different components of the water supply system perform correctly over their service life (their expected lifetime). This in turn avoids the occurrence of a major fault or breakdown in the water supply system that calls for corrective maintenance that is many times more expensive. In some cases, the problem may require full replacement of a costly item of equipment, which also takes a significant amount of time to achieve. As a result, the service level of the water supply system will reduce or even be interrupted over the period of maintenance, causing significant inconvenience to users and reducing the income of the water utility.

Utilities should always ensure that an adequate level of preventive maintenance is in place for all of their assets in the water supply system. This requires that adequately skilled persons are employed as operators or maintenance crew, and that they are provided with the proper tools. A strict and regular schedule of work is also required to ensure that preventive maintenance is carried out at the appropriate time. The next section considers strategies and plans for maintenance.

6.3 Maintenance strategy

Utilities with a strong focus on the preventive maintenance of assets can save substantial time and costs, avoid service interruptions, and increase their revenue.

A good maintenance strategy will detail:

- how the maintenance activities will be organised (on a regional and area basis)

- how maintenance will be carried out (using own technicians, or outsourcing to skilled technicians outside the utility, or both)

- clear descriptions of how the assets are expected to function with proper maintenance

- information and documentation requirements, for example a log of parts replaced, inspections made, recording of any incidents (unexpected events)

- prioritisation of assets for routine inspection and maintenance (the more important items, such as main pumps, needing more frequent inspection and maintenance).

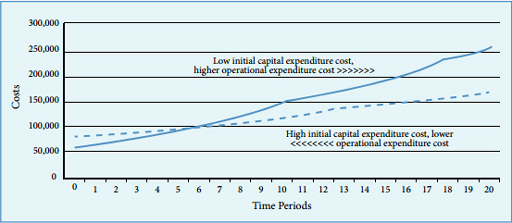

At times key decisions have to be made to replace old or damaged equipment. Adept utility managers plan and decide in advance which assets require replacement and when. These decisions may be made based on past experience or on the opinions of individuals, although this may be unwise because experience and opinions vary from one individual to another. One technique that can assist in making objective decisions uses the concept of life-cycle cost. (An objective decision is one based on facts, unlike a subjective decision, which is one based on personal feelings or opinions.) The life-cycle cost of an asset is the sum of its one-time, non-recurring costs (for example, its purchase and installation costs) and its recurring costs (such as its operating cost, maintenance cost and disposal cost) over the life of the asset.

Look at Figure 6.5, which shows two life-cycle cost trends. The solid line shows the trend for an asset with a low purchase cost but high operating cost over time, whereas the broken line shows the trend for an asset which has a high purchase cost but low operating cost over time. Note that both graphs show cumulative costs (the total costs accumulated over the time period shown). The graph demonstrates that a high initial cost does not mean an asset has the highest life-cycle cost. Similarly, a low initial cost does not mean lowest life-cycle cost. Utility managers and technicians can use graphs such as these to help take decisions when replacing assets or acquiring new ones.

6.4 Maintenance plans

Maintenance plans are prepared based on the maintenance strategy that has been formulated. The plan will outline the maintenance activities, their timing or frequency and the information needed for the record for each asset. It will also take into account the current condition of the asset, and its criticality (degree of importance) for the water supply system. Based on the plan, activities such as inspections, parts replacement and preventive maintenance will take place.

Retta is drawing up a maintenance schedule for various items at his water utility. In terms of criticality, how should he rank the following items?

- The computer used for billing customers.

- The pump at the water intake.

- The vehicles used by the leak detection team.

- The control system for the rapid gravity filter.

A recommended ranking would be (starting with the most important):

- The pump at the water intake.

- The control system for the rapid gravity filter.

- The vehicles used by the leak detection team.

- The computer used for billing customers.

6.4.1 Spare parts

Many water treatment and supply systems fail because of a lack of spare parts. Managers should be proactive and order adequate quantities of the parts that fail frequently. Doing this has the benefit of allowing repairs to be undertaken immediately, instead of time being spent going to the market to search for the appropriate part.

Standardisation (meaning keeping everything the same) of equipment and parts benefits operation and maintenance because fewer types of each part need to be stocked (thus making stock management easier), and purchasing bulk quantities of the same type of part brings savings. Standardisation also reduces the number of skills required to install and maintain equipment, so that more members of staff would be able to carry out the work(Barreto Dillon, n.d.).

6.4.2 Asset register

An asset register is a listing of all the fixed assets of an organisation and information pertaining to the assets. For a water utility the assets would be a list of all the equipment and buildings. For a piece of equipment the following information would be recorded: a description of the item, with technical drawings, its acquisition date, its service life, location and cost; the manufacturer’s details; the serial number of the item; details of the warranty and insurance; operating instructions; and maintenance requirements. Details of failures that occur when the asset is in use, and how they were caused, are also useful as they help in drawing up supplementary guidance on operation and maintenance, based on experience with the equipment.

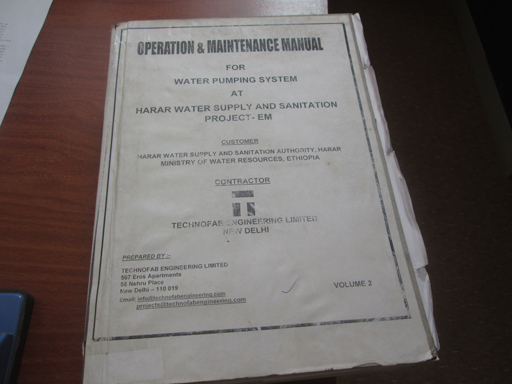

6.5 The Operation and Maintenance Manual

A key element of ensuring timely and adequate maintenance of water treatment and supply systems is the Operation and Maintenance Manual (Figure 6.6). This manual is prepared immediately after construction begins and before operation starts, and is the basis for the day-to-day running of the system.

A well-prepared Operation and Maintenance Manual contains the following:

- A detailed description of the system, with drawings.

- Health and Safety advice for all aspects of the water treatment and supply operation, ranging from how to lift heavy objects to what to do if someone is exposed to chlorine gas.

- Instructions for starting up and operating each of the water treatment processes and the system (e.g. of pumps) for delivery of the water, with details of the various parameters that need to be controlled (such as the flow rate through a rapid gravity sand filter, maximum flow rate permissible through the delivery system, etc.). These instructions are often referred to as standard operatingprocedures or SOPs. Essentially, a standard operating procedure is an established procedure to be followed in carrying out a given operation.

- The procedure to adopt in emergencies that can occur during the water treatment and supply process (for example, what to do if the inlet pump at the water intake point stops working). Plant operators should be trained in emergency procedures (such as how to overcome the emergency, who to contact, etc.) and mock emergencies should be enacted to allow staff to practise emergency procedures and be thoroughly familiar with what to do when a real emergency happens.

- Lists of tasks to be undertaken and at what frequency. There should be separate lists for daily tasks and weekly, monthly and annual tasks. Box 6.1 shows a typical list of daily tasks and, for comparison, example annual tasks are shown in Box 6.2.

Box 6.1 Example daily tasks in running a water treatment plant

- Check water meter readings and record water production.

- Check and record water levels in storage tanks.

- Check chemical solution tanks and record amounts used.

- Inspect chemical feed pumps.

- Check and record residual chlorine at the chlorine contact tank and in the distribution system.

- Inspect inlet pumps, motors and controls.

- Record inlet pump running times and pump cycle starts.

- Complete a daily security check.

Box 6.2 Example annual tasks in running a water treatment plant

The schedule for these tasks is spread throughout the year with some allocated for January, some for February, etc. so that workload is managed sensibly. Some of these tasks may need to be completed three or four times a year.

- Overhaul chemical feed pumps.

- Inspect and clean chemical feed lines and solution tanks.

- Calibrate chemical feed pumps.

- Operate all valves inside the treatment plant and pump-house. Maintain log continuously throughout the year.

- Review emergency response plans.

- Inspect chemical safety equipment and repair or replace as needed.

- Inspect, clean and repair control panels in pump house and treatment plant.

- Inspect storage tanks for defects and deficiencies, and clean if necessary.

- Flush the distribution system and exercise/check all fire hydrant valves.

- Perform preventive maintenance on treatment plant and pump house buildings.

6.6 Training and capacity building

It is essential that members of staff are adequately trained to operate and maintain the water treatment and supply system. The training can begin with a classroom-based introduction (Figure 6.7) to the whole system, which is then followed by a structured training programme, where the trainee is exposed to different parts of the water treatment and supply system, and is given on-the-job training. Here, the trainee works alongside an experienced staff member until he or she is familiar with components and comfortable to conduct the desired operation and maintenance independently. Where the management of the water utility observes a lack of capacity, immediate measures must be taken to build the required technical skills of the operators and maintenance crew.

6.7 Coping with natural disasters

Some towns in Ethiopia are located in areas prone to natural disasters. What are the natural disasters that have been experienced in Ethiopia?

Flooding is a problem in many parts of the country and earthquakes have also been experienced.

Water utilities in areas with a history of flooding or earthquakes should prepare adequately so that water supply is not affected. In 2014 there were serious floods in Gambela, Afar, SNNPR and Somali regions (Figure 6.8).

At times of natural disasters, the need to provide adequate and clean water to communities is crucial. There are good reasons for this. Other services such as electricity supply and transportation will be affected, limiting people’s access to safe food and health services. If clean water is also not available, the health of people will be at serious risk. Utilities must therefore plan and be prepared for such eventualities. Mock emergency exercises should be carried out on given water supply systems to develop detailed lists of actions to ensure that resilient systems that can withstand difficult conditions are in place to serve the community.

The following are some key points to consider to ensure resilience during floods.

- If wells are the source of water, the topmost reach of the well-casing should be raised above any known level of past flooding. Back-up generators should be installed on a stable foundation at a height that minimises damage by flood water.

- The well should have protective structures around it to prevent damage and avoid infiltration of contaminated surface water into the well.

- In treatment plants, sand bags should be available as flood barriers around buildings that house equipment, and windows should be boarded up.

- Switchboards and other electrical components should be installed at a height where floodwater cannot reach them.

It is not possible to protect water systems completely from all forms of natural disaster, for example earthquakes, but by forward planning and preparedness, it is possible to mitigate the worst impacts.

Summary of Study Session 6

In Study Session 6, you have learned that:

- Water utilities have many different departments, each with specific responsibilities. The Operation and Maintenance Department is vital for ensuring the continuous supply of good-quality water.

- Operation refers to the activities and procedures needed to keep a system running.

- Maintenance is the planned technical activity, or an activity taken in response to a breakdown, to keep a system operating. The former is referred to as ‘preventive maintenance’ and the latter as ‘breakdown maintenance’.

- Preventive maintenance contributes to continuity of water supply, thus reducing disruption to service, which can be costly to put right. It also ensures that the full service life of equipment is achieved and consequently saves money for the water utility. Continuity of service further means that the income from the sale of water is not interrupted.

- Life-cycle costing is a means of arriving at an objective decision when considering the purchase of assets.

- Maintenance schedules for assets should be based on their criticality to the water supply system.

- Having a stock of spare parts enables repairs to be carried out quickly.

- Standardisation of equipment and spares simplifies stock management, reduces purchase costs, and reduces the range of staff skills required for repairs, thus increasing the chances of more people being able to undertake repairs and maintenance.

- The Operation and Maintenance Manual is the guide by which the water supply system is run, and contains a description of the system, Health and Safety advice, instructions for starting up and operating equipment, emergency procedures, and listings of the required tasks, with timings.

- Staff should be adequately trained in operation and maintenance, and technical capacity should be built up in the water utility.

- Measures must be in place to ensure that natural disasters do not affect water supply.

Self-Assessment Questions (SAQs) for Study Session 6

Now that you have completed this study session, you can assess how well you have achieved its Learning Outcomes by answering these questions.

SAQ 6.1 (tests Learning Outcome 6.1)

In the paragraph below there are gaps for words. Insert the appropriate word from those listed here:

asset register; assets; criticality; life-cycle cost; operation and maintenance manual; regular maintenance; resilient; stakeholders; standardisation; standard operating procedures.

A water supply scheme is being planned in a town in Benishangul-Gumuz Region, in western Ethiopia. Different groups of people, referred to as ………………, who will be affected by the scheme, are called for a meeting. Their main worry is that floods will affect the new treatment plant but the Planning Engineer assures them the plant will be ……………… They are also worried about costs and whether decisions will be made objectively. The Finance Manager at the water utility tells them they use a technique based on ……………… that will help them make the right choice. The equipment and buildings, often referred to as ………………, will be well looked after through ……………… The frequency of maintenance will be decided by considering the ……………… of each asset. For the benefit of new members of staff, full details of all the assets are kept in the ……………… New plant operators and technicians will have the ……………… available to guide them in the ……………… of the water supply system. Within it are ……………… to use when starting up and operating equipment. A major issue is spare parts, since the town is several hours from Asosa, the Region’s capital. Again, this has been considered – the water utility has opted for ……………… of all its equipment and parts to make stock keeping and maintenance much easier, thus ensuring continuity of water supply.

Answer

Here is the completed paragraph.

A water supply scheme is being planned in a town in Benishangul-Gumuz Region, in western Ethiopia. Different groups of people, referred to as stakeholders, who will be affected by the scheme, are called for a meeting. Their main worry is that floods will affect the new treatment plant, but the Planning Engineer assures them the plant will be resilient. They are also worried about costs and whether decisions will be made objectively. The Finance Manager at the water utility tells them they use a technique based on life-cycle cost that will help them make the right choice. The equipment and buildings, often referred to as assets, will be well looked after through regular maintenance. The frequency of maintenance will be decided by considering the criticality of each asset. For the benefit of new members of staff, full details of all the assets are kept in the asset register. New plant operators and technicians will have the operation and maintenance manual available to guide them in the operation of the water supply system. Within it are standard operating procedures to use when starting up and operating equipment. A major issue is spare parts, since the town is several hours from Asosa, the Region’s capital. Again, this has been considered – the water utility has opted for standardisation of all its equipment and parts to make stock-keeping and maintenance much easier, thus helping to ensure continuity of water supply.

SAQ 6.2 (tests Learning Outcome 6.2)

Put the names of the Departments alongside the following water utility activities.

| Activity | Department responsible |

| Interviewing candidates for the role of operator | |

| Distributing information on how customers can reduce their water consumption and save money | |

| Repairing a sewer pipe that has been broken by a developer digging a trench to lay telephone cables | |

| Checking that the water that goes to the consumers is safe | |

| Making sure that the water supply is continuous | |

| Helping Ayinabeba, a new customer, to process the paperwork for water supply at her house | |

| Sending water bills out to customers |

Answer

| Activity | Department responsible |

| Interviewing candidates for the role of operator | Human Resources Management |

| Distributing information on how customers can reduce their water consumption and save money | Corporate Affairs |

| Repairing a sewer pipe that has been broken by a developer digging a trench to lay telephone cables | Sewerage |

| Checking that the water that goes to the consumers is safe | Water Quality Assurance |

| Making sure that the water supply is continuous | Operation and Maintenance |

| Helping Ayinabeba, a new customer, to process the paperwork for water supply at her house | Commercial and Customer Care |

| Sending water bills out to customers | Finance |

SAQ 6.3 (tests Learning Outcome 6.3)

Which of the following is not the duty of an operator at a water utility?

- a.Checking that the inflow to the treatment plant matches water demand.

- b.Monitoring the various water treatment operations for efficiency.

- c.Planning for the increased demand of water due to population growth.

- d.Measuring the residual chlorine level of the treated water leaving the plant.

- e.Making sure there’s an adequate stock of water treatment chemicals on site.

- f.Ensuring that wastes from the plant are properly disposed of.

Answer

The answer is c. Planning for increased demand of water is done by the Planning Department.

SAQ 6.4 (tests Learning Outcome 6.4)

Distinguish between the two types of maintenance at a water utility and give reasons why one of them is better.

Answer

The two types of maintenance are breakdown maintenance and preventive maintenance. Preventive maintenance is better because it helps prevent breakdowns and ensures that the assets can be used until the end of their service life. By undertaking preventive maintenance, crises – which are costly – can be avoided.

SAQ 6.5 (tests Learning Outcome 6.5)

How should electrical equipment be protected from floodwaters?

Answer

All electrical equipment should be installed at a height that the floodwaters are unlikely to reach.