Resource 3: Making pots

![]() Background information / subject knowledge for teacher

Background information / subject knowledge for teacher

An example using a pottery wheel Clay can be made into vessels because of its unique physical properties. The molecular structure of clay means it has a ‘plastic’ quality, allowing it to be shaped into an infinite variety of forms. Subject these forms to sufficient heat and they are altered into a rock-hard material, making them both functional and durable. Clay is composed of the most common elements found in the Earth’s crust and, as a result, is found throughout the world, beneath our feet. Clay was put to use by nearly every culture, often with extraordinary results. Pots can be made with bare hands using clay lubricated with water. |  Centering the clay on the kick wheel |

The potter, bearing down on the clay with their hands, then centres the clay. The fingers are used to first form the floor of the pot and then, to pull the walls of the clay up, typically into a cylindrical shape. Then the potter gently shapes the pot into the desired form, using the fingertips, as the wheel continues to spin. |  Opening up the clay |

Once fully formed, the pot is cut off the wheel head with a wire and removed. The process is then repeated with the next ball of clay. |  Shaping the clay |

When the work has dried to a leather-hard state, the pot can be trimmed. Handles are attached at this stage. Certain types of decoration can be added. Once pots are bone dry, they can be bisque-fired in a kiln. This produces a hard yet porous vessel. |  Pulling a handle for a mug |

Each pot is dipped directly into a bucket of glaze that has been mixed to the consistency of heavy cream. The stoneware glazes consist of a number of naturally occurring minerals such as feldspar, silica, whiting (limestone) and clay. Iron oxide is added in various amounts for colour. | |

Once the kiln is fully loaded, the door is bricked shut. The firing process takes 18 hours. The pots are gradually heated until they reach 1,250 °C, which is white heat. At several points during the firing, the kiln is starved of oxygen. This reduction atmosphere causes oxygen to be removed from the clay and the glazes. This process of reduction and reoxidation of the pots results in rich, earth-toned glazes. |

An example using pinch pot construction

With pinching gestures, you can mould clay into objects such as animals or make a bowl, a pot, a cup etc. While this form of pottery seems basic, you can get a feel for the clay you are working with and you will get to know the limits of your clay. (Does it bend easily? Does it dry fast? etc.)

To make a bowl, a pot or a cup, begin with a ball of clay. Push your thumb into the centre. Then pinch up the walls.

Turn the piece as you pinch. This will help you to keep an even thickness in the walls of the piece.

Gently pat the bottom on a flat surface to create a flat spot on the bottom of the piece.

Example of traditional pot – an African bracelet bowl used for storing bracelets

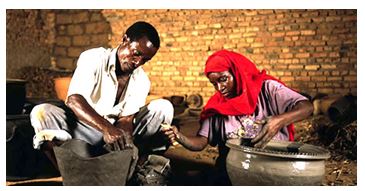

Rwandan arts and crafts

A wide range of traditional handicrafts is produced in rural Rwanda, ranging from ceramics and basketry to traditional woodcarvings and contemporary paintings. A good selection of crafted artefacts can be viewed in the main market or street stalls in Kigali, while an excellent place to peruse and purchase modern artworks is the capital’s Centre for the Formation of Arts.

A distinctively Rwandan craft is the cow dung ‘paintings’ that are produced by a local cooperative in the village of Nyakarimbi near the RusumoFalls border with Tanzania. Dominated by black, brown and white whorls and other geometric abstractions, these unique and earthy works can be bought in Kigali, but it’s worth seeing how the paintings are reflected in local house decorations.

Resource 2: Assessment sheet for research presentations