Background (Determining a spring force constant)

Background

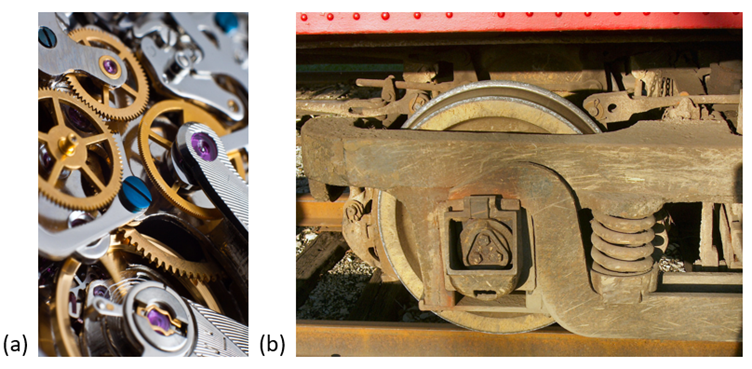

Springs are found in most mechanical devices from the propelling mechanism used by a simple mechanical pencil, to the source of energy storage in a wind-up clock and the shock absorbers in the suspension of trucks and trains (Figure 1).

Figure 1 (a) a spring used as an energy store in a mechanical clock (the spring is located in the lower portion of the image); (b) a spring used as a shock absorber in the undercarriage of a train.

A key property of a spring is that when it is either compressed or extended by the application of a force, it will return to its original shape and length once that force is removed. This property is call elasticity. Forces that stretch or pull a spring are called tensile forces and those that compress a spring are called compressive forces.

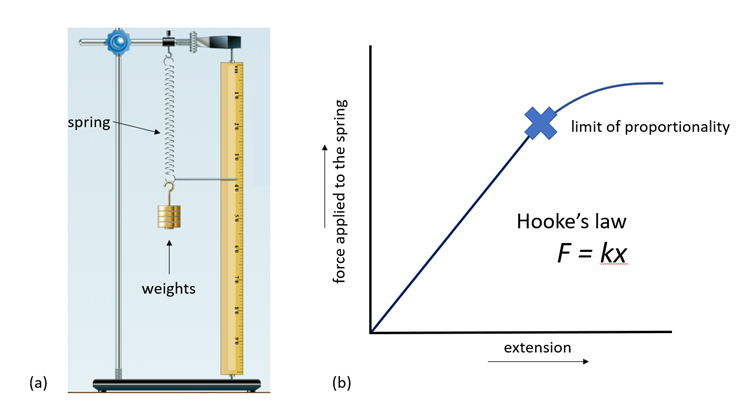

Metal springs are elastic because the bonds between the metal atoms are also elastic. The elasticity and stiffness of a spring is determined by the type of metal or metal alloy it is constructed from and the thickness and shape of the wire. Figure 2 shows the characteristic behaviour of a coiled spring, which extends as more weight is added to it.

Figure 2 (a) a spring mass system used to measure the extension of a spring as more weights are added to it; (b) a graph showing the extension of a spring with increasing force.

|

What type of force is being applied to the spring shown in Figure 2? |

The graph of extension against applied force in Figure 2 shows that the initial change in the length of the spring is linear and proportional to the force applied. However, as more force is applied the elastic limit of the spring is reached, after which point, if more force is applied the spring will have been stretched beyond its ability to return to its original length, and inelastic deformation of the spring occurs. The point at which the amount of extension is no longer proportional to the applied force is called the limit of proportionality, as indicated in Figure 2 (b). The graph in Figure 2 shows that beyond the limit of proportionality the spring resists extension, however in some instances a spring might undergo a sudden increase in extension before breaking. The point at which this sudden increase occurs is called the yield point.

The spring force constant of a spring is a measure of its stiffness up to the limit of proportionality and the behaviour of a spring during the region of proportionality is described by Hooke’s law:

F = kx

Where F is the force applied in newtons (N) to a spring; k is the spring constant and x is the extension of the spring in metres (m). You will discover how weight (mass) is converted to newtons in the ‘Practical activity’ section of this lesson.

By rearranging the Hooke’s law equation, it is possible to calculate the spring force constant if both the force and extension are known:

k = F/x

As force is measured in newtons (N) and the extension in metres (m), the units for the force constant are N/m:

k (N/m) = F (N)/x (m)

In this lesson you will use a spring mass system to measure the force constant of three different springs with varying degrees of stiffness.

Previous: Lesson objectives Next: Practical activity