2 Microbes in sewage treatment

All living things, including ourselves and microbes, need food to grow, maintain and repair their cells, and to provide a source of energy for life. However, we cannot digest all of the food we eat and what remains undigested, ends up in the sewage system. About 10 billion litres of sewage are produced every day in England and Wales and this has to be treated to remove harmful substances and pathogenic microbes before the waste can be safely released into the environment. The main component of sewage is organic matter (undigested food) but there are other substances such as oil, heavy metals, nitrogen and phosphorous compounds (from artificial fertilisers and detergents) which also have to be removed. Here you will consider the important role of microbes in the sewage treatment process.

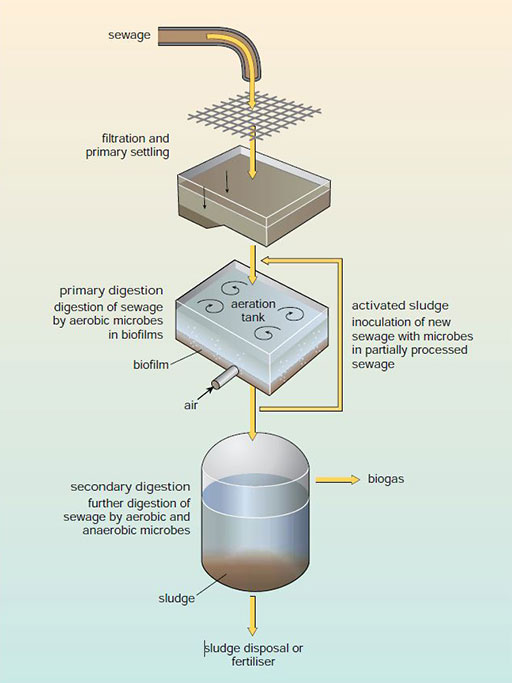

Sewage is actually a mixture of all types of waste water, including rain water and domestic water from toilets, baths and sinks. When sewage arrives at a treatment works (shown schematically in Figure 5), it is first filtered to remove large objects (e.g. condoms, tampons and cigarette ends) which have got into the system. These usually go to a landfill site or incinerator. The remaining material is then allowed to ‘settle’so that much of the solid material drops to the bottom of a tank. This solid material is then removed and usually buried in landfill, burnt or, after further treatment, used as fertiliser on agricultural land.

What then remains is the liquid portion, or effluent, which is rich in suspended organic matter and some pathogenic microbes. This liquid portion will ultimately be released into rivers or the sea but it is vital to first reduce the organic matter content and eliminate harmful microbes. To do this the liquid is fed into an aeration tank containing a complex community of microbes. The contents of the tank are mixed mechanically with air or air is bubbled through the tank. The microbes then use the organic material in the sewage as their source of carbohydrate for respiration.

The oxygen in the air allows the microbes to respire aerobically.What are the products of the aerobic respiration of carbohydrates like glucose?

Aerobic respiration can break down carbohydrates completely, producing just carbon dioxide and water (together with energy needed for the microbes to stay alive).

Aerobic respiration is the most efficient way of breaking down organic matter although some compounds in the effluent are not broken down completely. The tanks often contain porous solid materials, on which biofilms can develop, increasing the numbers of microbes and so the efficiency of the breakdown process. During this process, a fairly solid material known as activated sludge is formed. This contains a mix of microbes and undigested material. Since it contains all of the essential microbes to break down incoming waste, some of it is added to batches of new sewage (Figure 5). After this aerobic digestion, and a variety of other purification procedures, the liquid portion of the sewage is usually safe to discharge into rivers or the sea. The remaining activated sludge material is subjected to various other types of biological processes to reduce further the amount of organic matter it contains. Anaerobic bacteria are often used in this subsequent stage, since, although they grow more slowly, they can break down more complex materials that are difficult to degrade using microbes that respire aerobically. The gases produced in this anaerobic process are carbon dioxide and methane, a mixture called biogas, which can be collected and subsequently burned for energy production.

Sewage processing reduces the concentration of potentially harmful bacteria such as E. coli and Salmonella in the original sewage as many of them die during the processing because the conditions are not appropriate for them. It is also important to reduce the amount of organic compounds in the effluents released into rivers from sewage works. If this is not done, then microbes naturally present in the river use the organic compounds as a source of energy and reproduce in huge numbers. Since they respire aerobically, they use up much of the oxygen dissolved in the water, leaving little for other organisms such as invertebrates or fish, many of which will die. Sewage must therefore be treated to reduce the amount of organic matter, and thus reduce the Biological Oxygen Demand or BOD, defined as the amount of oxygen required by the aerobic microbes to decompose the organic compounds in a sample of water.

The process of sewage treatment can be thought of as a complex form of composting. The compost heap which you may have in your garden is like a miniature sewage treatment works. The centre usually becomes anaerobic as existing oxygen is used up. Closer to the top of the heap aerobic processes take place. Apart from the raw material, the other big difference between a sewage treatment works and a compost heap is that inside a compost heap, temperatures become high – well above 60 °C – which is detrimental to most species of microbes, but in which some can flourish.

Sewage works rely on the diverse capabilities of microbes for the complete process to be effective. Name three types of microbial activity that are used in the process and one that is not.

Aerobic and anaerobic respiration and fermentation play an important role in sewage treatment. Photosynthesis is generally not used in the sewage works because it is a process that builds organic compounds from carbon dioxide, whereas the objective of sewage works is to break down organic compounds.

Many of the microbes used in food and in industry are anaerobic so that they must be cultured in conditions without oxygen. In principle, anaerobic culturing is very similar to aerobic culturing. However, it does involve some specialist equipment and procedures which are described in Box 1.

Box 1 Growing anaerobic microbes and large-scale culturing

Why do you think anaerobic culturing would be more challenging than aerobic culturing?

Although some anaerobic microbes can tolerate small amounts of oxygen, many are obligate anaerobes, which means they are killed by oxygen. When culturing them, special efforts must be made to ensure that at no time during their manipulation using aseptic techniques are they exposed to oxygen.

Microbiologists have devised a range of methods for culturing anaerobic microbes. One of the most important pieces of equipment is a cabinet flushed with a gas such as nitrogen which allows manipulations to be carried out in an oxygen-free environment. The operator carries out the work through rubber gloves connected to the inside which prevents oxygen from entering the cabinet. When anaerobic microbes are cultured on Petri dishes, the dishes are also stored in airtight containers that are constantly flushed with nitrogen or carbon dioxide to keep them anaerobic. Many anaerobic organisms also need some unusual elements to grow, and these are added to the culture media.

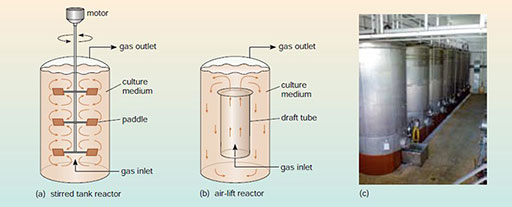

Growing anaerobic microbes on a large scale is essential for the industrial processes of brewing beer, making wine and carrying out other types of fermentation and for producing large quantities of microbes, for example yeast for bakeries. This is often done in giant metal vats called fermentation reactors which can hold many hundreds or thousands of litres of microbial culture (Figure 6c). The vats are provided with sensors to measure temperature and nutrient levels that allow computers to control the conditions within the reactors to ensure maximum growth of the microbes. One of the difficulties with such cultures is preventing the microbes from settling to the bottom of the vats.

Why is this likely to be a problem?

Those microbes which settled first would be covered by those settling later and therefore would not be able to access the nutrients in the culture medium. They would probably die and decompose, and their breakdown products could then contaminate the culture, as well as resulting in a lower yield of microbes from the whole vat.

To prevent settling, the vats can be stirred mechanically by large paddles (Figure 6a) or oxygen-free air (mostly nitrogen) can be bubbled through to circulate the contents of the vat (Figure 6b). If aerobic microbes are being cultured, then similar vats are used but air or oxygen is bubbled through.

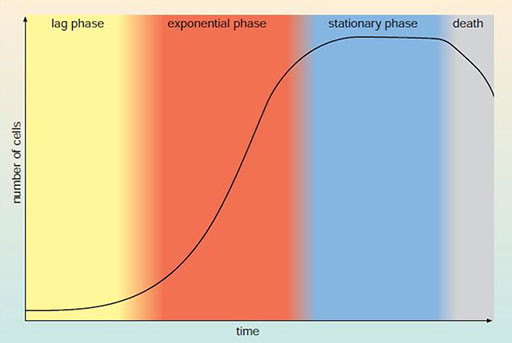

The growth of populations of microbes in the fermentation reactors (and in all other situations too), follows the basic pattern shown in the growth curve in Figure 7. When microbes are first added, they begin growing and dividing slowly as their enzyme systems adjust to the presence of new nutrients. This is referred to as the lag phase. After a period of time the microbes begin to grow and divide very rapidly to take advantage of the favourable growth conditions – the exponential phase. There may then come a point at which the microbes have used up some vital nutrient in the growth medium and they are no longer able to divide – the stationary phase. Eventually the microbes become old and start to die – the death phase. These growth stages are important for industrial processes. To produce the maximum amount of microbes and microbial products, they must be constantly provided with new nutrients to prevent them entering the stationary phase, hence the valves and tubes entering the fermentation reactors in Figure 6c. These are then harvested by being extracted from the medium in which the microbes are growing.