2 The brewing process

Have you ever been to a brewery? If not, now’s your chance! In order to illustrate the brewing process, you will now visit (virtually, of course) the Hook Norton Brewery located in the village of Hook Norton, Oxfordshire (Figure 7).

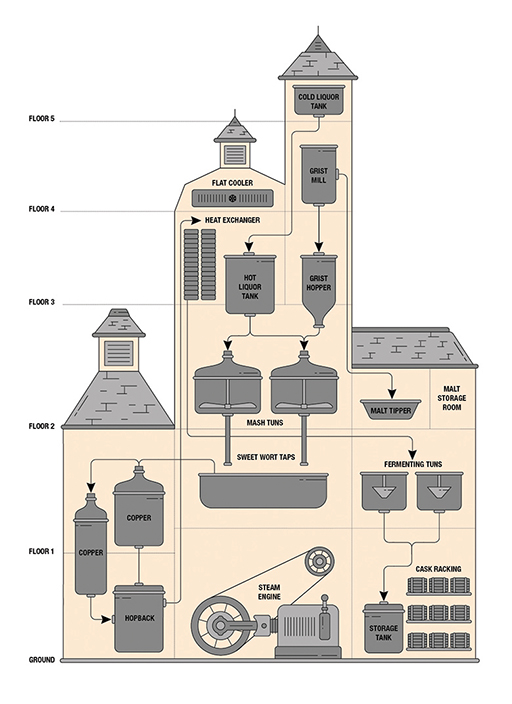

Hook Norton Brewery (referred to colloquially as ‘Hooky’) dates back to 1849 and is referred to as a ‘tower house’ brewery. This means that the stages of the brewing process flow logically from floor to floor, as illustrated in Figure 8.

In the following video you will learn from Mark Graham about why Hook Norton uses a tower house brewery.

Transcript

Now watch the actual brewing process utilised by Hook Norton.

Transcript

Activity 1 The order of the brewing process

After watching the video can you list the different constituents of the brewing process in order?

Discussion

The constituents are:

- malting

- mashing

- boiling

- fermentation.

These steps are summarised in the following sections.