2.2 Producing synthetic and semi-synthetic antibiotics

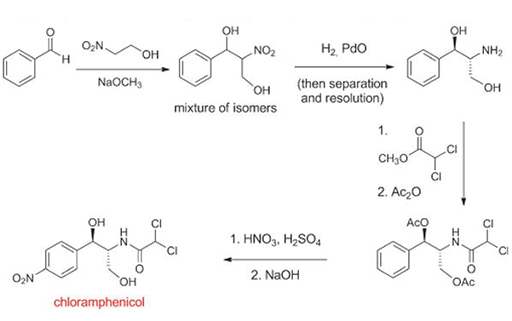

Antibiotics are very complex molecules. Synthetic compounds that resemble or mimic a natural antibiotic are rarely made for this reason. An exception is chloramphenicol (Figure 3). Novel synthetic antibiotics can be made in laboratories from scratch using a multi-step process that starts with the requisite chemical building blocks and ends with the pure compound. However, this process involves considerable development time and production costs.

Semi-synthetic antibiotics represent a half-way house. They are made by chemically modifying the active part of a natural antibiotic to create a single new molecule. A large amount of natural antibiotic is produced by batch fermentation. Then it is purified and chemically modified to create new antibiotics with enhanced therapeutic activity. Promising compounds identified by screening chemical libraries can similarly be modified to enhance activity and safety.

Next, you will find out how many existing antibiotics are still effective against bacterial infection.