2.2 Mashing

During the mashing process, the starches released during the malting phases are converted into sugars which can be extracted for use by the yeast in fermentation. The cracked malt is mixed with hot water to create a mash as illustrated at Hook Norton in Figure 9.

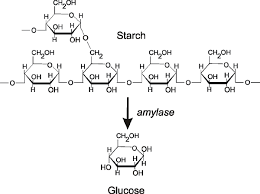

During the mash, naturally occurring amylase enzymes present in the malt convert the starches (long-chain carbohydrates) in the grain into smaller molecules or simple sugars such as glucose, needed by the yeast to ferment into alcohol (Figure 10).

Mashing results in the production of a substance rich in sugar known as the wort. The sugars produced need to be extracted so, during the process of sparging, hot liquor is sprayed onto the grain to wash the sugars along with the liquid into a copper kettle (Figure 11).