19.2.1 Human waste management

The basic requirements expected from a human waste (excreta) disposal method are:

- Surface water must not be contaminated.

- There should be no contamination of groundwater that may, in turn, contaminate springs or wells.

- Excreta should not be accessible to flies or other animals.

- There should be no handling of excreta; where this is unavoidable, it should be kept to a minimum.

- There should be no odours or unsightly conditions.

- The method used should be simple and inexpensive in construction and operation.

- The method should last for at least five years to be cost-effective.

In Study Session 18 you were introduced to some of the sanitation technologies that are used for human waste management. You may recall that WCs and pour-flush facilities were classed as wet or water carriage systems, also called drop-flush-and-discharge systems. The aqua privy or water privy is another in this group. Aqua privies consist of a latrine constructed above a watertight tank containing human waste and water. The wastewater from these systems is usually discharged to a septic tank or to sewers which carry it to a liquid waste treatment plant. The presence of adequate water is essential for all wet systems. For this reason, and also because of the cost involved, they are not recommended in most rural places where there is inadequate running water. For such areas, the recommended methods of sanitation are dry or non-water carried systems where there is no water needed to carry the waste offsite. In Study Session 20 you will learn more about the construction of pit latrines and other dry systems. Pit latrines are the most common type of latrine in Ethiopia.

Sanitation facilities have been classified in a different way by the WHO/UNICEF Joint Monitoring Programme (JMP), as ‘improved’ or ‘unimproved’.

Improved sanitation services or methods include:

- WC or flush toilet to piped sewer system or septic tank

- pour-flush latrine

- pit latrine with slab

- ventilated improved pit (VIP) latrine

- ecological sanitation (a type of latrine that converts human waste into useful material without damaging the environment or endangering human health).

These improved sanitation methods are described in Study Session 20.

Unimproved sanitation methods are all those that do not ensure there is no human contact with human excreta (see Figure 19.1). They include:

- service or bucket latrines (where excreta are manually removed)

- pit latrine without slab

- open latrines

- excretion in the environment (or simply, open field defecation).

Pit latrines may be classed as either improved or unimproved depending on the presence of a slab. Why does the presence of a slab make this important difference?

The slab that covers the pit is essential for ensuring there is no contact between the waste in the pit and the person using the latrine. This defines the difference between improved and unimproved sanitation.

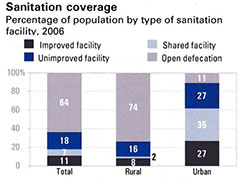

Figure 19.2 shows the sanitation data for Ethiopia and indicates the relative proportions of the population with access to improved and unimproved facilities. In this graph, open defecation is classified separately from unimproved methods. A fourth category, shared facilities, means sanitation that is otherwise acceptable but is shared between two or more households.

From Figure 19.2, what percentage of the rural population does not have access to improved facilities? How does this compare to the urban population?

74% of rural people use open defecation and a further 16% only have access to unimproved facilities. Therefore, a total of 90% of people in rural areas of Ethiopia do not have access to improved sanitation facilities. In urban areas, 38% of people (11% + 27%) do not have access to improved facilities.

19.2 Management of liquid waste