3.3.1 Wells and boreholes

Wells and boreholes can be described by their depth, or by the way they are constructed. They may also use different types of pump at the surface to raise the water.

Shallow wells

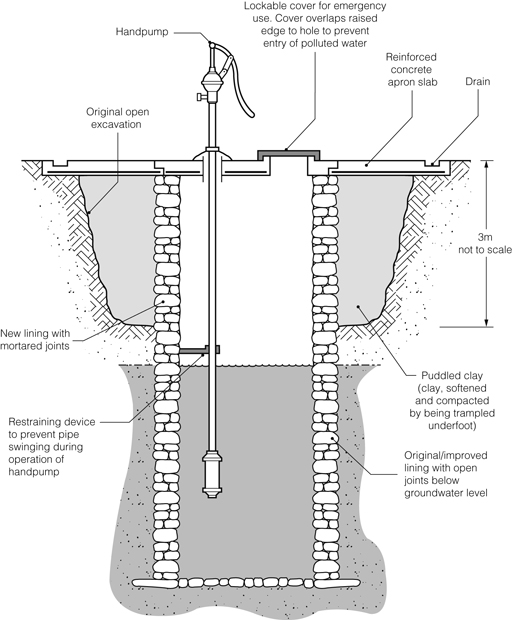

Shallow wells and boreholes usually have a depth of less than 30 m, although they can be as much as 60 m deep, especially in very dry areas of Ethiopia where the water table is low. Figure 3.4 is a diagram of a protected hand-dug well. Wells can be excavated by hand if the soil is not too hard or the water table is high. Hand-dug wells have a relatively large diameter because they have to be wide enough for a person to be able to stand inside and dig.

The inside wall of the top 3 m or so of the dug well should be made waterproof by constructing a well casing (lining). In small-diameter wells the casing can be a pipe, but in large wells the casing needs to be constructed in concrete from the top of the well down to a minimum depth of 3 m. The casing of the well should also be extended for a minimum of 60 cm above the surrounding ground level to prevent the entrance of surface run-off – that is, water that runs off the surface of the land, carrying debris, wastes and other pollutants with it as it flows. A concrete cover should be fitted over the well casing, as in Figure 3.5, to prevent dust, insects, small animals and any other contaminants from falling in.

Depending on the depth of the well, water may be drawn up by a bucket and rope or by using a pump. Hand pumps, such as the one in Figure 3.6, are built over the well and the concrete cover extends to cover the surrounding ground. The immediate area of the well should preferably be fenced to keep animals away. The area surrounding the well should be graded off (i.e. should slope away from the well) in order to prevent the flow of storm water run-off into the well. Any pipework associated with the pump that enters the well needs to have watertight connections so that it operates efficiently. The well, pump, pipework and associated structure should be regularly disinfected using chlorine solution to eliminate pathogens and ensure the water is safe to drink.

Water can also be drawn from a well using a rope pump (Figure 3.7). A long continuous loop of rope, with washers at regularly spaced intervals, runs around a wheel at the top of a well and around a smaller roller encased below the water line. The rope runs through a PVC pipe and, as the wheel is turned, water is drawn up the pipe by suction. A rope pump can be made from recycled parts, such as bicycle wheels, scrap metal and plastic, and it can be mended quickly and cheaply.

Deep wells or boreholes

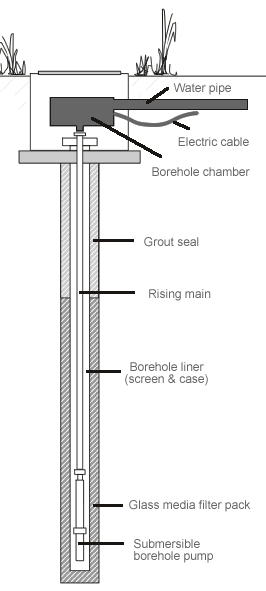

These are wells that have been sunk with drilling machines designed for constructing water extraction boreholes (Figure 3.8). These machines are able to penetrate through harder material that cannot be tackled by hand digging and can therefore pass through at least one impermeable layer of rock to a productive aquifer underneath. They typically obtain water from depths ranging from 30 to 60 m, but large urban supply boreholes can be much deeper than this. A casing of metal or plastic pipe is usually necessary to line the borehole and prevent the soil and rock from collapsing into it (Figure 3.9). The lower part of the casing must have suitable openings to allow water to enter the borehole from the aquifer, although in hard rocks – such as some of the volcanic aquifers of Ethiopia – the borehole can be left open and will not collapse.

At the surface, different types of pump may be used including hand pumps like the one in Figure 3.6. For larger boreholes in urban areas electric or diesel-powered pumps would be used.

3.3 Groundwater