5.2.1 Screening

To protect the main units of a treatment plant and to aid in their efficient operation, it is necessary to use screens to remove any large floating and suspended solids that are present in the inflow. These materials include leaves, twigs, paper, rags and other debris that could obstruct flow through the plant or damage equipment. There are coarse and fine screens.

Coarse screens (Figure 5.3) are steel bars spaced 5–15 cm apart, which are employed to exclude large materials (such as logs and fish) from entering the treatment plant, as these can damage the mechanical equipment. The screens are made of corrosion-resistant bars and positioned at an angle of 60º to facilitate removal of the collected material by mechanical raking.

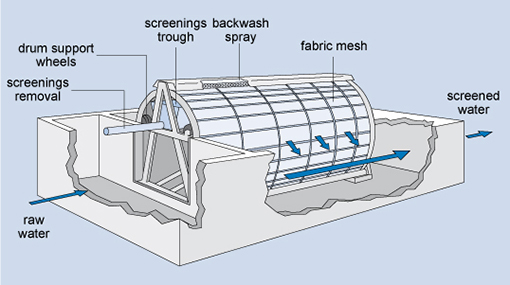

Fine screens, which come after the coarse screens, keep out material that can block pipework at the plant. They consist of steel bars which are spaced 5–20 mm apart. A variation of the fine screen is the microstrainer (Figure 5.4) which consists of a rotating drum of stainless steel mesh with a very small mesh size (ranging from 15 µm to 64 µm, i.e. 15–64 millionths of a metre). Suspended matter as small as algae and plankton (microscopic organisms that float with the current in water) can be trapped. The trapped solids are dislodged from the fabric by high-pressure water jets using clean water, and carried away for disposal.

5.2 Stages in large-scale water treatment