7.3.1 Detecting leaks in water mains

Preventing leaks by using corrosion-resistant materials, following the correct procedures for pipe laying, and conducting regular checks and preventive maintenance is the best approach, but inevitably some leaks will still occur. The challenge is to find the leaks, which will probably be underground, and repair them as quickly as possible. This is active leakage control.

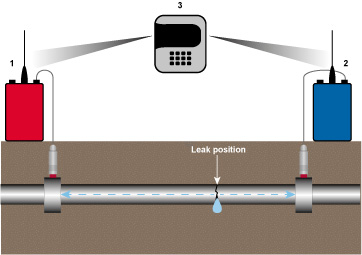

Leaks are usually detected from the sound generated by the escaping water. A device called a noise correlator (Figure 7.5) is used to listen to the leak from two different points and can pinpoint the exact location of the leak. The correlator can be used on both metal and non-metal pipes.

Typically, microphones or acoustic sensors (1 and 2 in Figure 7.5) are placed in contact with the pipe, at two points, to record the hissing sound emitted by a leak somewhere between the points. The sound data are sent to a noise correlator (3), which processes the information through a mathematical program to determine the difference in the times taken for the noise to travel from the site of the leak to each of the sensors. If the distance between the sensors is known, this timing information can be used to determine the location of the leak.

Leakage detection is best carried out at night when it is quiet and the use of water is minimal. Sections of pipe which have a high flow can then be closed off and investigated for leaks. In areas where there is only an intermittent supply of water, a water tanker can be used to put water into a section of pipe and pressurise it. Any leakage can then be easily detected.

Alternatively, devices called acoustic loggers (Figure 7.6) can be attached to pipes using magnets. They record and analyse the intensity and consistency of noise in the pipe. A significant change in the noise will signal a leak. This device has been used in Harar to detect leaks (Mohammed, 2015). A combined correlator-acoustic logger is also available. This reduces the time for detecting and pin-pointing a leak.

Another device is ground-penetrating radar, which reveals leaks by identifying disturbed ground or cavities around a pipe. It can be used to locate leaks where a correlator would be impractical due to noise created by pumps, etc.

Contrary to common belief, large leaks that spray water into the street, like the one in Figure 7.4, are not the major cause of water loss, since they are obvious and thus quickly found and repaired. The small leaks, which discharge water under the ground, are not obvious and can remain undiscovered for years, with the concomitant loss of a large amount of water. However, in a pressurised system, small leaks are noisy and can be detected easily, once suspicion is aroused about a possible leakage.

When carrying out a leak detection programme, it is best to concentrate on parts of the distribution system that are most likely to have a leak. These would be:

- areas where there have been leaks before

- areas where there is heavy traffic, because this would exert a load on the pipes, and also the vibrations caused by the traffic can cause damage.

Once a leak is discovered it has to be repaired quickly, so that wastage of water and money is avoided. Public opinion is also important – water seen gushing out onto the street for a long period quickly leads to accusations that the water utility is being complacent!

Special collars that fit around the pipe are used to repair small leaks. For large leaks, a smaller-diameter pipe may be inserted into the section of pipe concerned, so that the water flows through this new pipe (effectively a pipe within a pipe). Alternatively, the pipe section itself can be replaced.

7.3 Leakage prevention, detection and control