6.4.3 Mechanical-biological wastewater treatment

Wastewater treatment can be undertaken using a sequence of processes in a mechanical-biological system (Figure 6.12). This treatment is faster than using natural systems such as waste stabilisation ponds or reed beds and requires less space. These factors make it desirable for sewage treatment in towns with large populations where there is not enough land for natural systems. However, mechanical-biological systems are more expensive because of the equipment required and the need for skilled personnel to operate them.

These systems typically have three main stages: preliminary, primary and secondary treatment.

Preliminary treatment

In this first stage screens (Figure 6.13) remove large items such as pieces of wood, metal, rags, paper or plastic that have got into the sewerage system. Removing them protects the structures and equipment in the wastewater treatment plant. Paper and rags in the wastewater flow are sometimes shredded by comminutors, which are rotating, slotted drums equipped with cutting blades. The shredded material can then be returned to the flow further downstream without causing harm.

Small stones and grit have to be removed from the flow. Grit is comprised of very small pieces of sand, stone and possibly also glass and metal. All these materials can increase the rate of wear of mechanical equipment and can also settle easily in pipes, causing blockages. The grit settles out in grit channels (Figure 6.14) and can be removed daily by manual or mechanical means and dumped at a landfill site.

Primary treatment

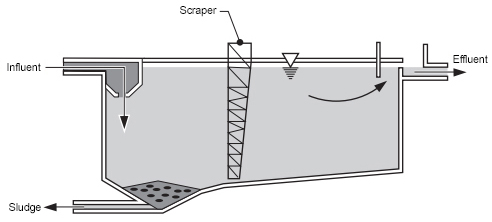

In the primary treatment stage, fine solids in the wastewater are removed by settlement in a sedimentation tank (Figure 6.15). A properly designed and well-operated primary sedimentation tank will reduce the suspended solids content of the wastewater by between 50 and 70%, and the biochemical oxygen demand (BOD) by between 25 and 40% (Crites and Tchobanoglous, 1998).

Secondary treatment

This is the biological stage of treatment. In secondary treatment the organic matter in the sewage is biodegraded by micro-organisms using oxygen. Oxygen levels are increased artificially by various means to ensure removal of organic matter. Also in this stage, ammonia in the sewage is converted to nitrate. This is followed by a second sedimentation stage to remove solids produced by the microbial activity. The treated effluent should be clear, free of pathogens and safe to discharge into a river or possibly be reused for irrigation.

6.4.2 Reed beds