5 Transport biofuels: biodiesel and bioethanol

Biodiesel is an alternative fuel to diesel, and bioethanol can be used in place of petrol. Biodiesel cannot be used on its own in traditional internal combustion engines but can be blended with traditional petroleum fuel. Bioethanol can be used on its own or in a blend. Overall, biofuels make up 5% of the petroleum blend in the UK. The UK Government set a target that 5% of road transport fuel should be from renewable (non-fossil fuel) sources by 2010.

Biodiesel is produced from oil-seed crops, such as oilseed rape, sunflower oil, palm oil and soybean oil. Oilseed rape is the main oil crop in the UK and yields approximately 1300 litres of biodiesel per hectare planted. The fuel is synthesised from the oil seeds by mixing them with two industrially sourced chemicals, methanol and either sodium hydroxide or potassium hydroxide. This reaction causes the formation of fatty acids and glycerol, with the fatty acids reacting further to produce biodiesel. Most biodiesel production is currently in Europe, but it is not limited to the developed world. Tanzania, for example, has started producing biodiesel from the nuts of the croton tree (Croton megalocarpus), a plant native to Africa. Several countries, notably India, are using biodiesel obtained from Jatropha curcas oil as a fuel; indeed the trains that run between Mumbai and Delhi now use diesel that contains 15% biodiesel obtained from Jatropha. This plant has several advantages as a source of biofuel: it can tolerate drought conditions, and it grows on poor land that is unsuitable for agriculture and so does not compete with food production.

Germany used significant quantities of bioethanol as a biofuel during the Second World War, but recently interest in this fuel source has spread. Currently, countries using bioethanol include Brazil, France, the USA, the UK, Argentina and South Africa. In Brazil use has been particularly widespread; however, this has been at the expense of large tracts of natural vegetation including rainforests. It is estimated that one-third of cars in Brazil run entirely on bioethanol and the remaining two-thirds use a mixture of bioethanol and petrol (gasoline). Bioethanol is produced by fermenting plant sugars, or it can be made by taking starch-rich plant material, treating it to convert the starch to sugars, and then fermenting them. A third, less productive, method is to take stems or leaves and convert the tough cellulose from cell walls into sugars for fermentation; but this requires additional steps, including treating the plant material with sulphuric acid and heating to convert the cellulose into sugars, or using enzymes to do this. Both sulphuric acid and the necessary enzymes have to be produced by industrial means and this incurs an extra cost.

Question 18

List some of the crops used for biodiesel production.

Answer

Oilseed rape, sunflower, palms, soybean, croton tree nuts and Jatropha curcas.

Question 19

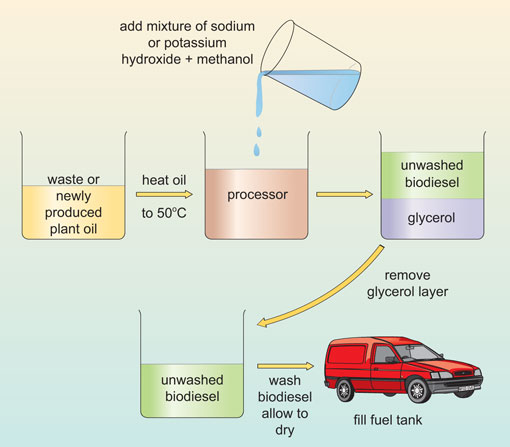

Figure 14 shows the stages involved in making biodiesel, summarise these stages in your own words.

Answer

Oil is extracted from the crops and heated to 50 °C in a processor before being mixed with sodium or potassium hydroxide and methanol. The oil is allowed to separate into unwashed biodiesel and glycerol and the glycerol layer is then removed. The biodiesel is washed with water and allowed to dry. The washed biodiesel is stored until it is used.

Question 20

In Figure 15, there is a step labelled fermentation, what is the product of this step?

Answer

The product is bioethanol.

Bioethanol is currently produced by the fermentation of sugar by microbes. Microbes use the sugar as a food source and convert it to ethanol. In order for the ethanol to be used as fuel it needs to be separated from the other components of the fermentation reaction, usually by the process of distillation. Typically the mixture is heated and, as the ethanol boils at a lower temperature than the other components, it is transformed into a gas first and this gas can be collected and then condensed (transformed back to liquid bioethanol). The purified and bioethanol can be mixed with petrol for use in car engines.