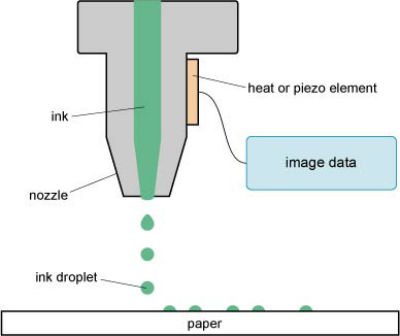

As the name suggests, the process works similarly to traditional 2D printing. Material is added drop by drop rather than layer by layer, by controlling the flow of material using piezoelectric flow restrictors similar to those used in standard desktop inkjet printers. As drops are deposited on top of previous drops, three-dimensional structures can be formed.

Manufacture:

The process can be summarised as follows:

- A control system positions the print head above the position requiring material addition.

- Droplets of material are deposited from the print head onto the surface where required.

- As material is added and solidified drop by drop the first layer is created.

- Further layers are built up on top of previous layers by increasing the height of the print head.

- After deposition, post processing often includes removal of support material or UV curing.

Materials:

- Proven for a limited range of polymeric materials. The formation of a droplet depends on sufficient viscosity in the polymer melt. This limits application to specific polymers. Fortunately, several common and popular polymers fit into this requirement. For instance:

- polypropylene

- HDPE

- PS

- PMMA

- PC

- ABS.

Design:

- Specific benefits include:

- Capable of multiple material and multiple colour printing.

- Extremely fine drop production permits very fine detail to be printed.

- Component design is limited by:

- Strength and thoroughness can be influenced by many factors including time of build, atmosphere and even polymer colour.

- Overhanging regions need extra designing.

- Support structures can only be placed where they can be removed (i.e. not inside internal voids like those required to create a ball).

See Also: Direct metal deposition (DMD), Fused deposition modelling (FDM), Selective laser melting (SLM).

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews

just to start people off if not Why NOT??? the OU can make Good Money from this...