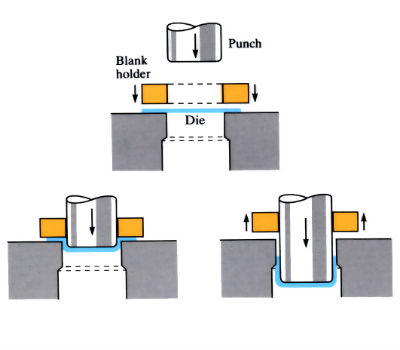

"Single-acting" die assembly

The blank is produced on a separate press. The blank holder pressure prevents wrinkling.

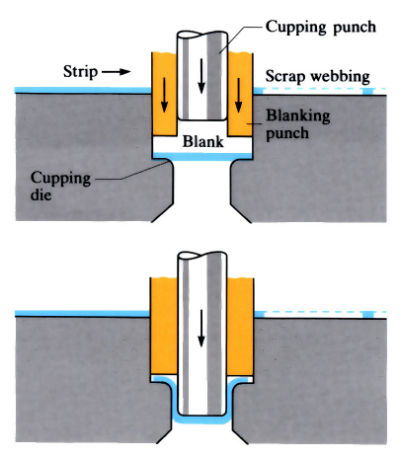

"Double-acting" die assembly

The blank is produced in the same die. The outside punch acts as a blank holder.

Manufacture:

- Drawing is a process of forming flat sheet blanks into hollow shapes by means of a punch that causes the metal to be formed into the die cavity. If the depth is one or more times the diameter of the final shape, then the process is called deep drawing.

- The simplest method of producing cup shapes is to employ a “single-acting” machine that is fed by hand or automatically, with blanks that have been produced on a separate blanking press.

- Modern “double-acting” or “triple-acting” cupping machines blank out and cup the metal strip in one press action. The strip is automatically fed into the die area. Often the machines are design to blank and cup several components at a single stroke using multiple punches and dies.

- Multi-stage transfer presses (either mechanical or hydraulic) with up to 10 stations are used for long production runs (> 50,000 parts year-1) of small-to-medium sized artefacts such as brass caps for electric lights.

- Mainly mechanical presses up to 1000 tons in capacity are used for deep drawing.

- In some high speed operations, lubrication of the blank is required: usually soap or graphite in tallow.

Materials:

- Deep drawing is usually associated with the more ductile metals and alloys.

- 70-30 brass is deep drawn into cartridge cases.

- Aluminium and some of its alloys are deep drawn into a wide variety of shapes such as cans, milk churns and washing-machine tubs.

- Other materials include cupro-nickel, copper, titanium, iron and nickel-based alloys. Nimonic alloys require lubricating oils with small additions of molybdenum disulphide.

Design:

- The deformation limit or the limiting draw ratio (LDR) is the maximum blank diameter that can be drawn into a cup without failure.

- The draw ratio or the percentage reduction up to 48% on first draw, are considered achievable in most ductile materials.

- Embossing the bases of deep drawn components with beads adds rigidity and strength, and prevents the phenomena of dishpanning.

See Also: Stretch forming, Fluid and rubber die forming, Superplastic forming and Vacuum forming.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews