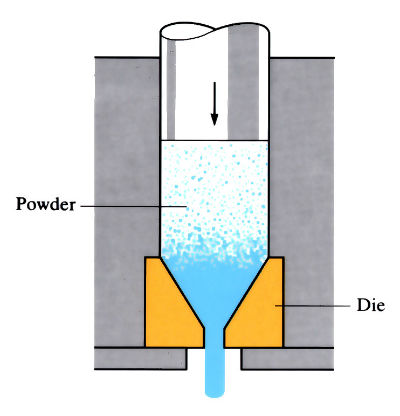

The cold extrusion of metal powder

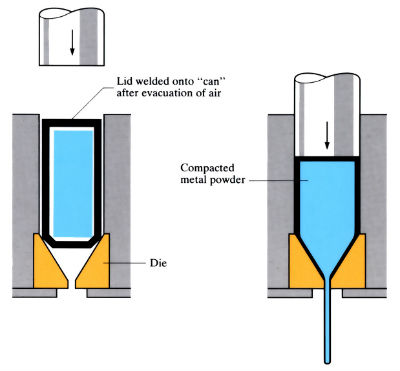

The hot extrusion of a "canned" refractory metal powder

Manufacture:

- Powders can be consolidated by cold or hot extrusion.

- Cold extrusion of powders requires a considerable amount of binder (up to 50%) such as paraffin waxes, starches, benzol, resins or shellac. This has to be removed during sintering of the cold extruded material, giving a large amount of porosity. The process is used for the production of carbide twist drills and cutters.

- Hot extrusion of powders is usually carried out by “canning” the powders in a mild steel can, which is evacuated and sealed at its end. This prevents oxidation of the powders at the high temperatures (which can be as high as 1400˚C for some of the refractory metals). High extrusion ratios can be achieved, leading to good densification to near theoretical density.

- Process is a batch type process and in some instances has been superseded by the hot isostatic and Conform techniques.

Materials:

- Cemented carbides are cold extruded with the addition of a suitable binder.

- The materials that are hot extruded in powder form include the following:

- SAP (sintered aluminium powder)

- refractory metals such as tungsten and molybdenum

- beryllium

- cermet fuel elements (UO2 in a stainless steel matrix)

- magnesium alloys

- nickel-based superalloys

- High temperature refractory metals have to be protected against oxidation by the canning technique.

- High strengths and good ductility can be achieved in hot extruded powder extrudates.

Design:

- Cold extrusion is mainly used to produce components with uniform cross sections, such as twist drills or milling cutter shapes.

- Hot extrusion is useful for the production of long lengths of rods, bars, tubes and other shapes.

- Canning technique necessitates removal of mild steel skin by machining or chemical techniques, and allowance should be made for the reduction in component dimensions.

See Also: Hot isostatic pressing, Powder forging, Hot extrusion and Conform Process.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews