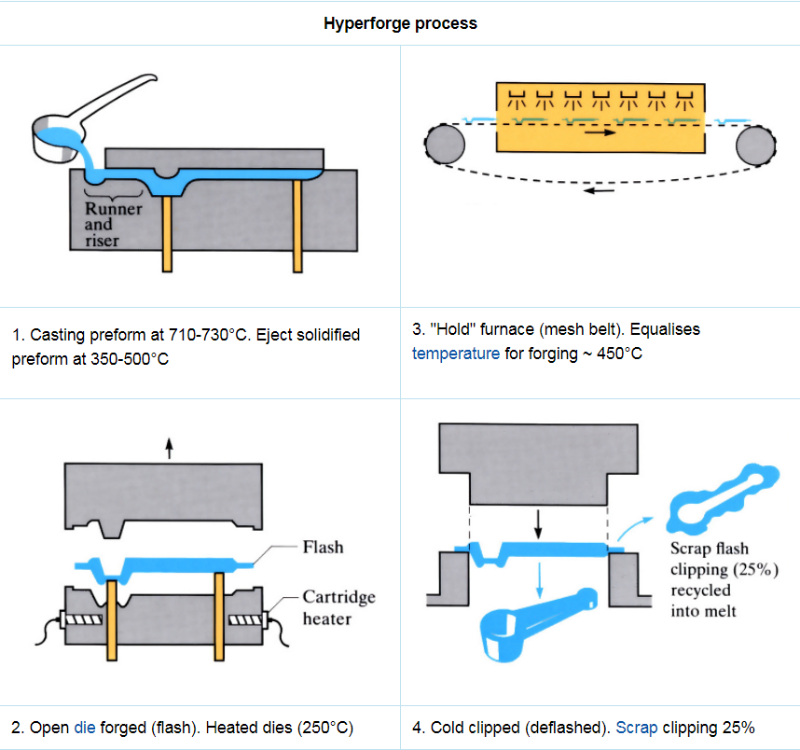

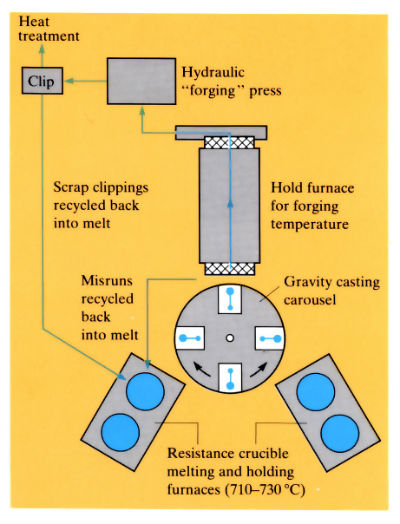

Manufacture:

- An alternative to die casting, forging and the “Acurad” process, with a high yield of >98%.

- Water-cooled (<60˚C) Cu-2%Be moulds coated with graphite every 50 castings. Mould life is exceptionally good.

- Fe-5%Cr hot work steel forging dies are coated with graphite before each forging and pre-heated to 250˚C using cartridge heaters. Die life in excess of 300,000 forgings.

- Medium to high production rates of 180–250 components h-1.

- Typical products include spider cranks for bicycles and small connecting rods for internal combustion (IC) engines.

Materials:

- Low cost ingot feedstock is up to half the price of bar stock used for conventional forging.

- Similar materials to those used for squeeze casting, i.e. aluminium casting and forging (6082/2014A) alloys.

- Rapid cooling and grain refining lead to a fine equiaxed grain structure which imparts anisotropic properties.

- UTS, 0.2% proof stress and percentage elongation compared favourably with fully heat treated wrought alloys. Typical “Hyperforge” properties for heat treated (T6) alloys are:

| Alloy |

Elongation at fracture (%) |

Tensile strength (MPa) |

0.2% proof stress (MPa) |

Fracture strength at 5 x 108 Hz (MPa) |

|

6082 |

8 | 310 | 280 | 124 |

| 2014A | 6 | 435 | 370 | 170 |

5. Fatigue and impact properties only slightly less than for wrought alloys.

Design:

- Design limitations are those of conventional forging processes, i.e. no re-entrant angles and small draft angles of approximately 5˚.

- Surface finish is dependent on die condition but is typically in the range 3.2–12.5 µm Ra.

- Dimensional tolerances of ±5 mm m-1.

- Clipping of forging leaves a “witness mark” which requires removal by finishing.

See Also: Low pressure die casting, cold forging and Acurad process.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews