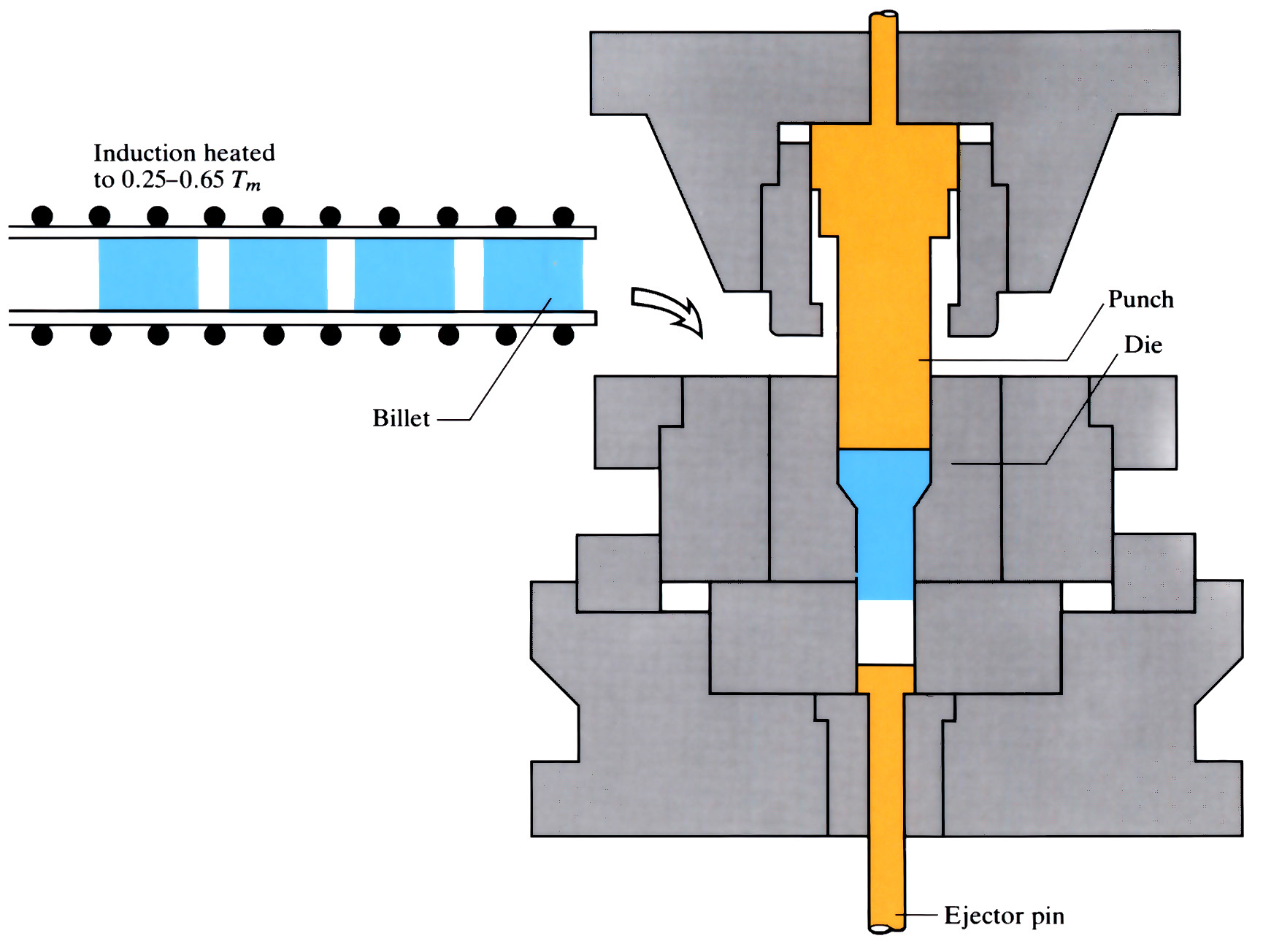

Warm forging of steel suction valve

- Requires accurate billet (±1 g).

- Billet does not need to be annealed unless combining cold and warm operations.

- Billet is heated by induction heater to 0.25–0.6 Tm (500–800°C for steel).

- Billet is lubricated with graphite (no need for phosphate/soap lubricants).

- Billet is warm forged in totally enclosed heated dies at lower loads than for cold forging.

Manufacture:

- Warm forging is used as an alternative process to cold forging, or is combined with cold forging.

- Usually applied for difficult-to-cold-forge materials such as alloy steels for induction hardening applications containing 0.4–0.5 wt% C.

- Requires accurate weight control of billets (±1 g).

- Billets are heated by induction heaters to temperatures of 0.25–0.6 Tm (e.g. steels are warm forged at 500–800˚C).

- The billets are then coated with graphite for lubrication during warm forging.

- These are then forged into totally enclosed dies with no flash formation.

- Hot work die steels are used for punches and dies.

- Lower forging loads are required than with cold forging, hence smaller-capacity presses can be used: e.g. maximum punch pressures for steel are:

cold forging (62% reduction) 2000 MPa

warm forging (62% at 600˚C) 1450 MPa - Any critical dimension might need to be tightened by the addition of an extra coining or sizing operation.

Materials:

- Generally the main advantage of warm forging over cold forging is that the range of materials can be extended from the soft metals into higher alloyed materials, which cannot normally be cold forged because of excessive forging loads on punches and dies.

- Low and medium alloy steels can be warm forged for higher duty applications or for applications requiring a change in post-heat treatment schedules (e.g. the change of low carbon case hardening steels to medium carbon (0.4–0.5% C) steels for induction hardening applications).

- Cr-Ni-V steels are used to produce socket heads for socket sets.

- Only a slight improvement in material properties compared with cold forging.

Design:

- Dimension and tolerance control is not as good as for cold forging.

- Tolerances:

- diameter 0.3–0.6 mm

- length 0.8–3.5 mm

- flange thickness 0.3–0.5 mm

- Surface finish: slightly oxidised on steel. 1.25–2.5 μm Ra.

See Also: Cold forging, hot forging (closed die) and Orbital forging.

This article is a part of Manupedia, a collection of information about some of the processes used to convert materials into useful objects.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews